192

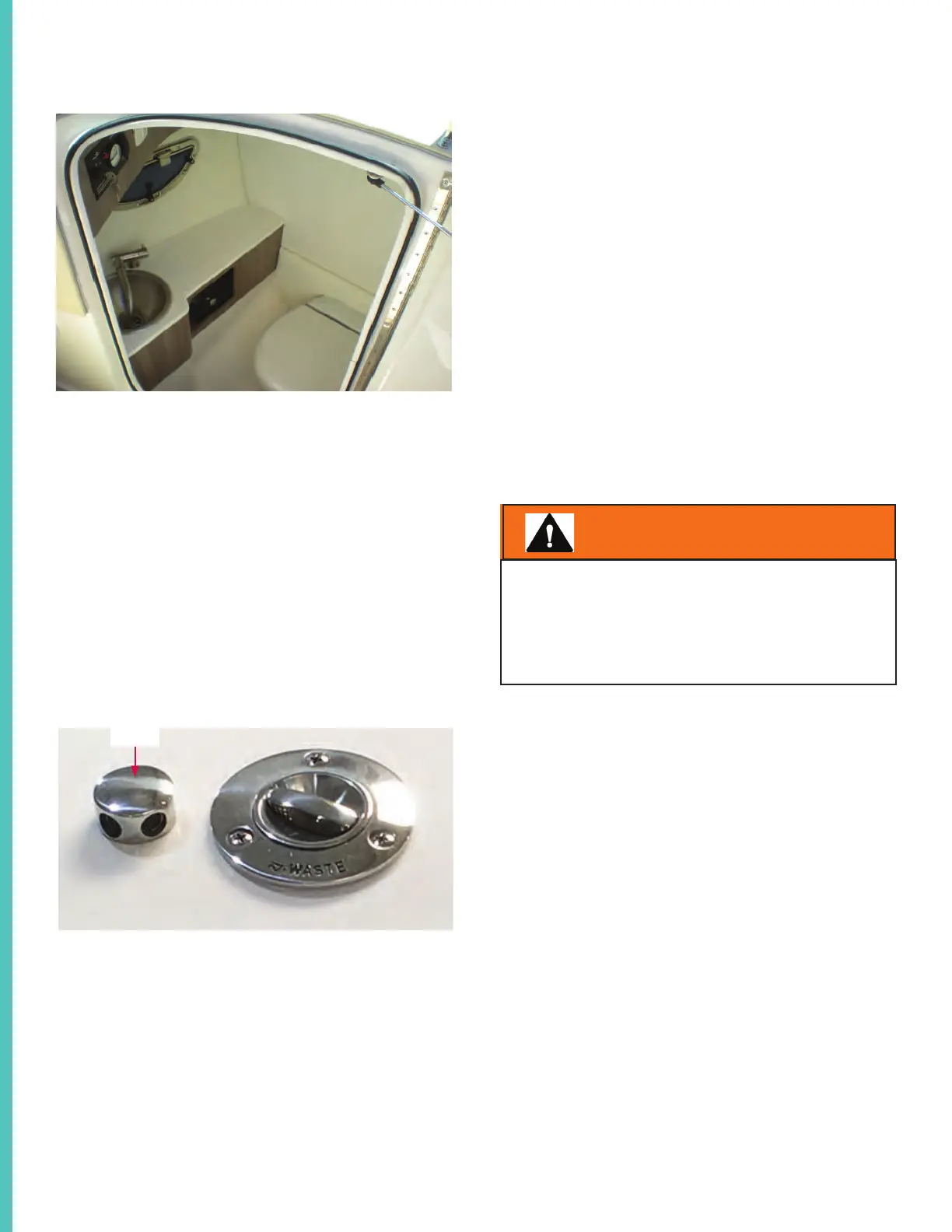

Toilet- Electric (Typical)

Introduction

If installed the electric toilet (head) uses turbine

technology to produce a clog-resistant, powerful

fl ush. It integrates an effi cient small footprint re-

sulting in the same features of larger units.

The toilet draws clean water from the fresh wa-

ter tank through a solenoid to fi ll the bowl. A wall

rocker type switch operates toilet fl ushing cycle.

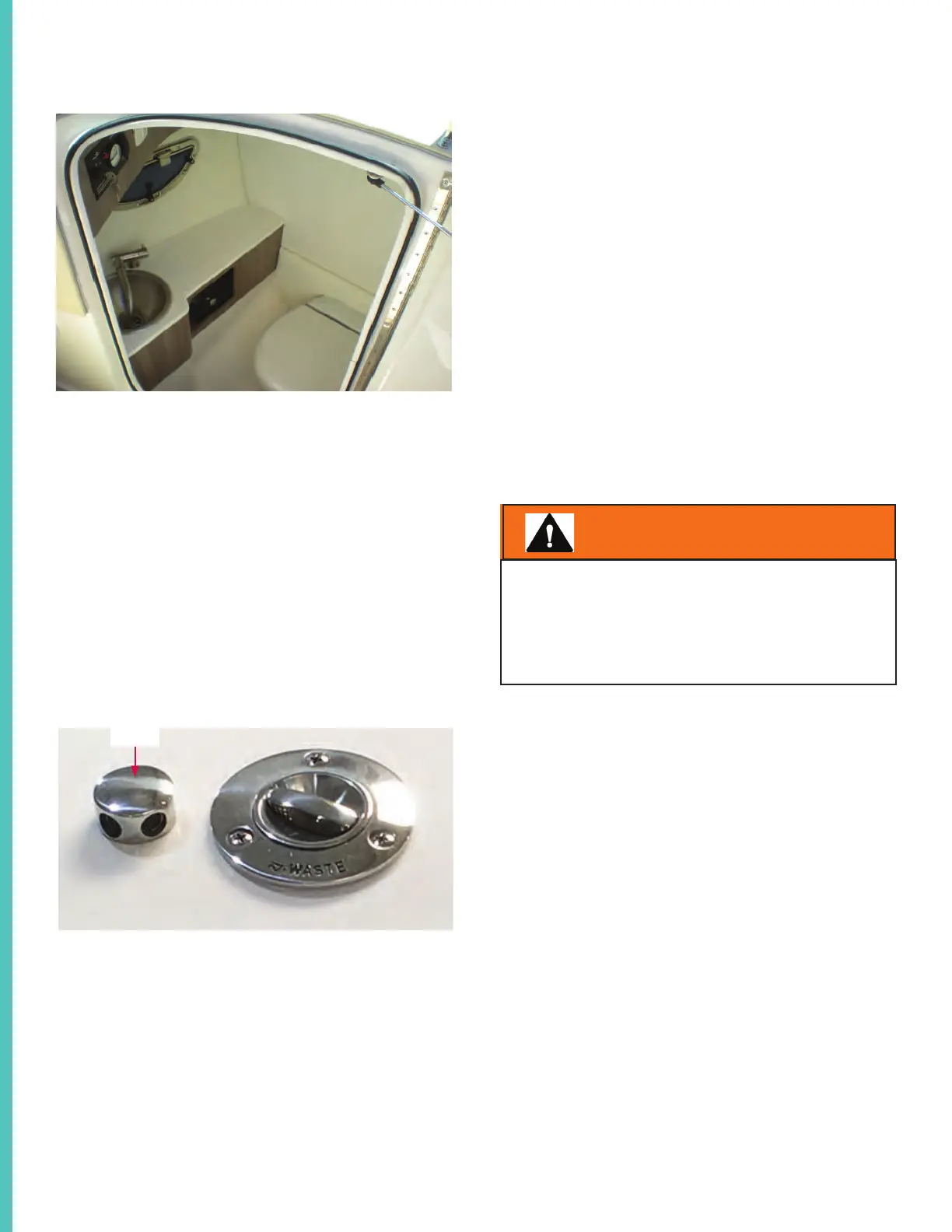

As an option a deck mounted pump-out fi tting is

used and is labeled “waste”. When the holding

tank is full as indicated by the wall rocker switch

a marina or pump out station can attach a hose

to the waste fi tting. When activated a pump will

evacuate waste waste from the holding tank.

WARNING

ALWAYS CHECK WITH LOCAL, STATE AND

COUNTRY WASTE DUMPING REGULATIONS/

AUTHORITIES

BEFORE ATTEMPTING TO PUMP WASTE

OVERBOARD!

TYPICAL ELECTRIC TOILET OVERVIEW

If installed a macerator system featuring an over-

board discharge pump uses an impeller to grind

up waste and send it to the holding tank or through

the hull bottom via a seacock fi tting during the over-

board discharge process. Note the seacock must

be in the “open” position to use the overboard dis-

charge feature. It is recommended to secure the

seacock in a closed position after an overboard

discharge cycle. You might want to keep a pack

of zip ties in the bilge tied to the seacock for this

purpose. With the seacock secured closed it adds

an extral layer of protection for following discharge

regulations.

The macerator pump is integrated behind the toilet

lower base. The pump is replaceable.

The toilet (head) electrical system is connected to

the house battery system thus using a 12 volt

DC power supply. The head is protected by a 30

amp resettable breaker on the D.C. distribution

panel located at the battery management panel.

If installed the macerator (overboard discharge

pump) is protected by a 10 amp resettable breaker

on the D.C. distribution panel located at the bat-

tery management panel.

TYPICAL PUMP-OUT WASTE FITTING/VENT

VENT

Loading...

Loading...