2.

Accelerator Operation

The Model B1 Accelerator is basically a normally-closed

valve with ½” NPT ports, that is highly sensitive to the rate of

air pressure change in a dry pipe sprinkler system. This de-

vice retains normal dry system air pressure in its top cham-

ber even though pressure in that system may be dropping

as a direct result from one or more sprinklers opening.

Fig. 1 illustrates a cross-section of the Model B1 Acceler-

ator in the “closed” position while being pressurized. Upon

initial setup, the Accelerator is filled by air from the dry pipe

system via a ½” NPT connection. Air passes through its

filter assembly (item #18) and passageway E to the de-

vice’s middle chamber. This air pressure also lifts the dia-

phragm assembly (Items #5 through #8) off of the push

rod (item #10) thereby opening up passageway G. The air

then completely fills the top chamber to the desired system

pressure level. When filled, the diaphragm assembly rests

on the push rod’s end and closes passageway G, except

for minor leakage which is designed to compensate for air

pressure fluctuations in the system.

Upon a significant air-pressure decay of the sprinkler

system piping (such as sprinkler activation), the retained

air pressure in the Accelerator’s top chamber exerts a net-

downward force across the diaphragm assembly (Items

#5 through #8). This forces the poppet (item #15) to open

thereby allowing system air pressure to pass out of the Ac-

celerator’s ½” outlet port and into the intermediate cham-

ber of the dry pipe valve (or to atmosphere depending on

the type of system to which it is installed). This in turn will

activate the dry pipe valve. Simultaneously, pressurized air

also passes through the Accelerator and closes the integral

Accelo-Check (items #11, #19 through #25) by pressuriz-

ing cavity H and preventing water and waterborne debris

from entering the internal restriction area in passageway

G. This increases the reliability of the Accelerator and re-

duces the maintenance which would otherwise be required

to clean it after each operation.

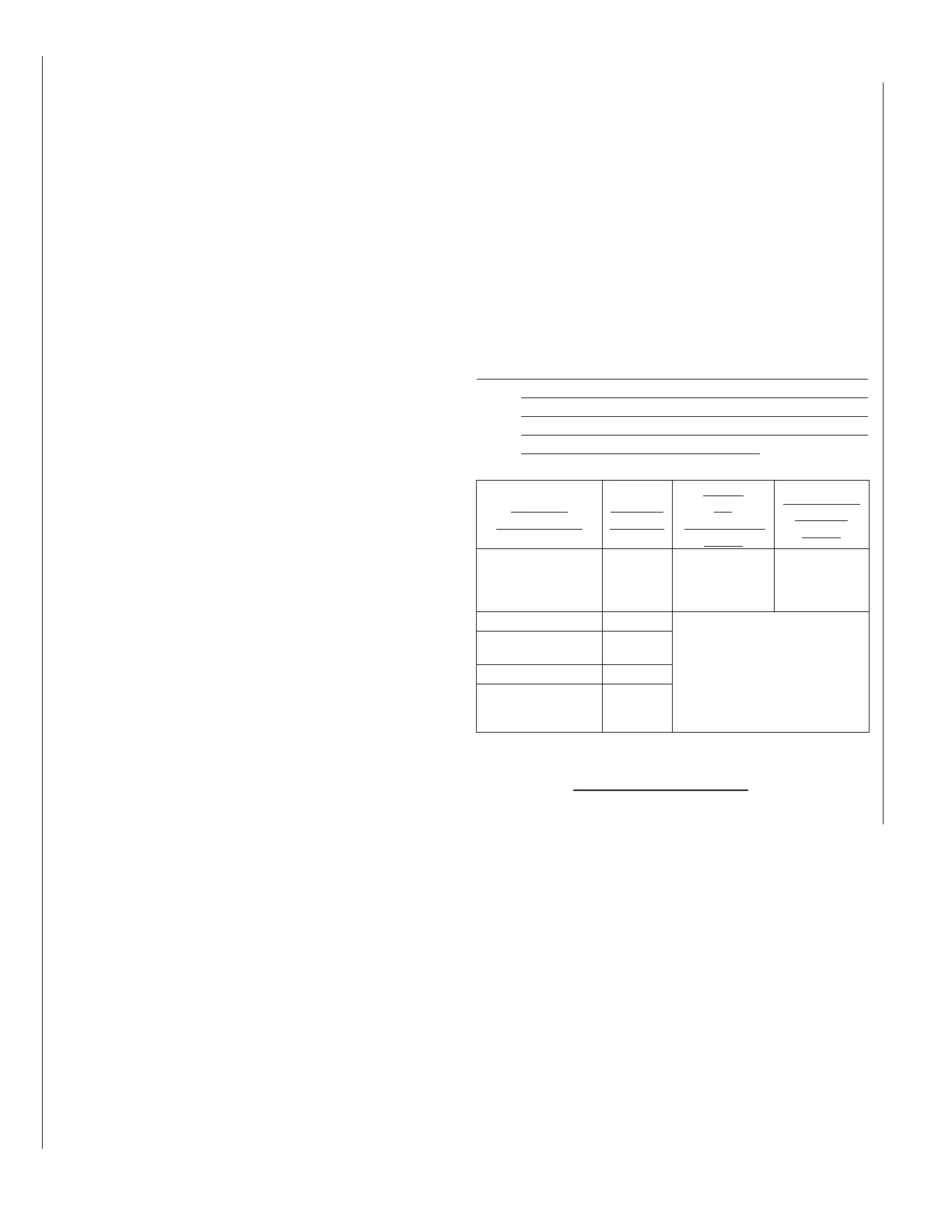

Installation

The Reliable Model B1 Accelerator is quickly attached

to the various Reliable-manufactured dry pipe valves/sys-

tems. The following table lists the figures in this technical

bulletin that illustrate the specific trim attachment locations

along with the complete component listing of their contents.

When installed into the basic trim of a Reliable Model D

Dry Pipe Valve (refer to Fig 2), the Accelerator’s ½” out-

let port should be directly connected to the intermediate

chamber of the dry pipe valve. In this specific application,

the Model B1 Accelerator is used like an exhauster that

directly assists the clapper of the dry pipe valve to open.

For installations into all other Reliable-manufactured dry

systems such as Models LDX, DDX-LP & EX (refer to Figs

3, 4 & 5), the Accelerator’s ½”outlet port should be vented

to the atmosphere. These other types of systems do not

utilize differential-type clappers that require additional air

pressure to operate. Instead, these systems all utilize a

Model LP Actuator to keep a push-rod chamber pressur-

ized to a certain level of air pressure. In these instances,

Dry Pipe

System Type

Refer to

Figure #

Model

B1

Accelerator

Part #

Accelerator

Trim Kit

Part #

Model D

(4” & 6”)

2 6301000300

6516000002

(Does not

include

Accelerator)

Model LDX (4” & 6”) 3

6516000003

(Includes Accelerator)

Model DDX-LP

(All Sizes)

4

Model EX (All Sizes) 5

Model DDX Type F

Preaction System

(All Sizes)

6

In addition and for more detailed instructions in connect-

ing the Model B1 Accelerator a specific type of system,

please go to www.reliablesprinkler.com and refer to the

pertinent technical bulletins describing those systems.

the Model B1 Accelerator speeds up the purging of the

air side of the Model LP Actuator, which in turn, vents the

push-rod chamber pressure of the main fire control valve

thereby causing its clapper to open and fill the system pip-

ing with water.

The ½” outlet port of the Accelerator should also be vent-

ed to atmosphere when installed into Reliable’s Model DDX

Type F Double Interlock Preaction systems (refer to Fig. 6).

As in the previously mentioned systems, the Accelerator

also helps to speed up the purging of air pressure in a

Model LP Actuator and the opening of the main fire con-

trol valve, however, no water will enter the sprinkler piping

until the normally-closed solenoid valve (installed in series

with the Model LP Actuator) of the trim becomes energized

open via some type of incoming detection signal(s).

Note: The Model B1 Accelerator may be capable of has-

tening the operation of non-Reliable-manufactured

dry pipe valves having intermediate chamber de-

signs. However, it has been tested and approved

only with Reliable Dry Pipe Valves.

Loading...

Loading...