9.

System Requirements

NFPA (National Fire Protection Association) 13 titled “In-

stallation of Sprinkler Systems”, specifies that Accelera-

tors (quick-opening devices) are required in dry systems

having capacities of more than 500 gallons. However, ex-

ceptions permit the omission of quick-opening devices for

larger systems when water can be delivered to the inspec-

tor’s test connection in less than 60 seconds.

• Reliable’s Accelerator is UL Listed for system volumes to

1500 gallons. This capability is also approved by FM.

• System pneumatic pressure must be maintained at a

minimum of 15 psi in order for the Accelerator to be

effective.

It must be cautioned that accelerator operation and water

delivery at the inspectors test connection does not occur

at the same time. There is a delay while the air is being

expelled through the inspectors test connection ahead of

the water. This time delay depends on the piping configu-

ration system size, available water supply and other factors

which are beyond the control of the accelerator and restrict

the system’s capability to deliver water in the 60 second

time requirement. While field installation experience will

aid in the determination of system size limitations, it is rec-

ommended that the Reliable Technical Service Department

be consulted when large volume systems are encountered.

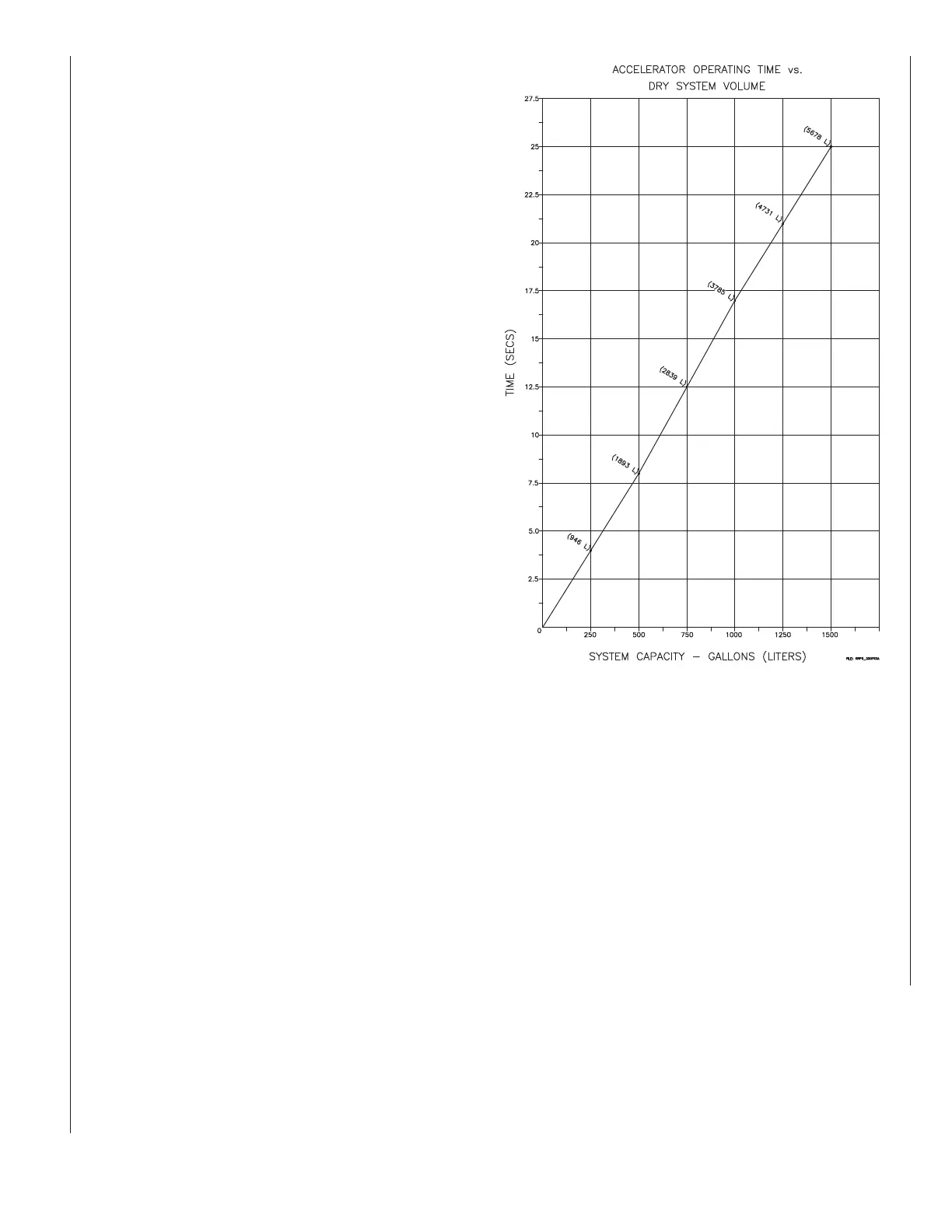

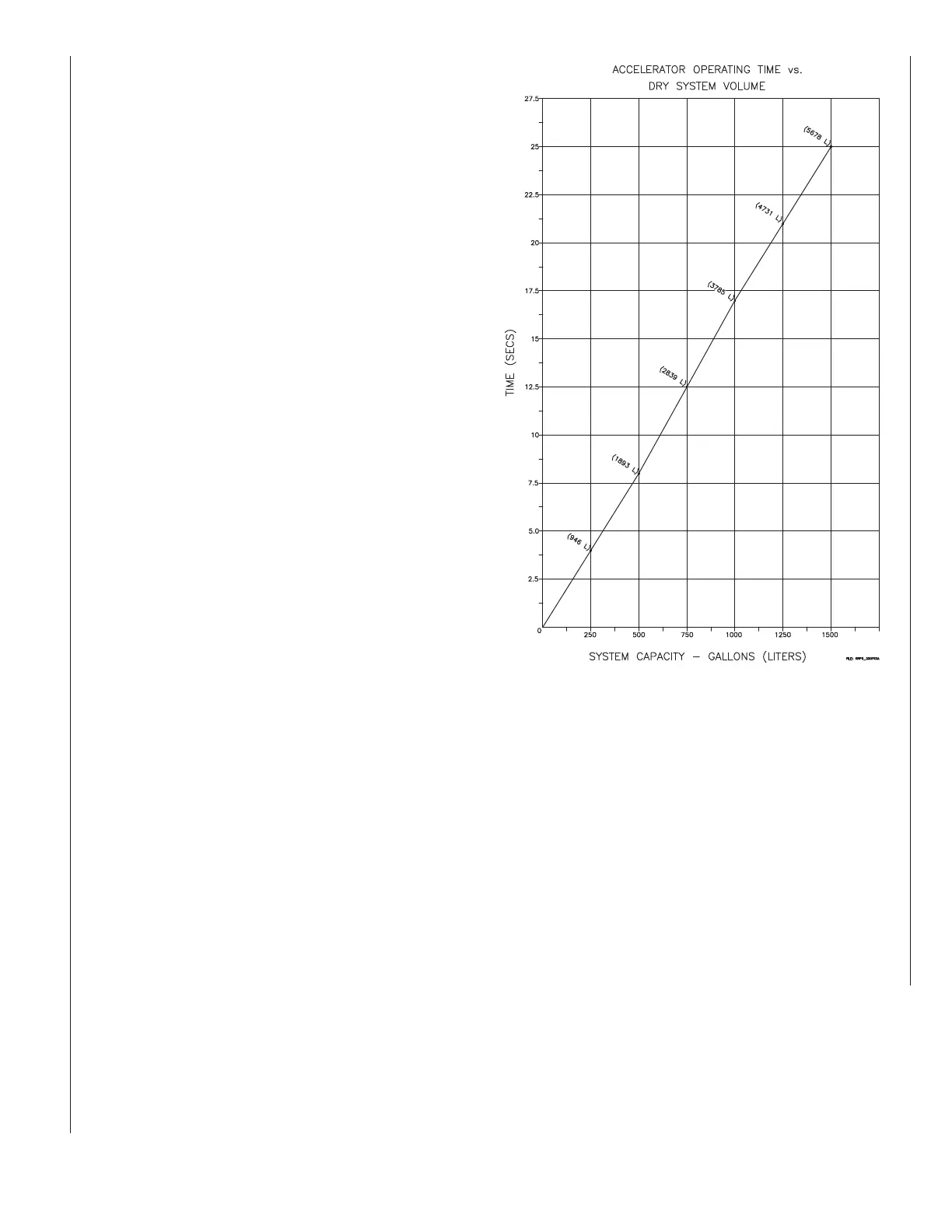

Figure 7 provides an approximate graph of actual Accel-

erator operating time versus system size when one sprin-

kler head opens. The time of operation of the Accelera-

tor is relatively unaffected by inlet pressures so the graph

applies for all normal dry system pressures from 25 psi to

50 psi (1.7 bar to 3.4 bar). As described in the following

section, water delivery time will significantly exceed the ac-

celerator operating times shown is Figure 7.

Resetting Procedure For Model D Dry Pipe

Valve Systems (Refer to Figs. 1 & 2)

1. Isolate the Accelerator by closing the valves A and

C, Fig.

2. Close the air and water supply valves to the dry pipe

valve. Drain and fully reset the dry pipe valve in ac-

cordance with its technical bulletin.

3. Re-close the main water supply control valve and

then re-open the dry pipe valve’s drain valve.

4. Remove Plugs B and E, Fig. 2.

5. Remove the body drain plug from the lower section

of the Accelerator, Item #3, Fig 1.

6. Remove the top chamber drain plug, Item #3, Fig.

1, from the side of the Accelerator. If water is pres-

ent in the top chamber, disassemble the Accelerator,

and clean and dry the top and middle chambers and

diaphragm assembly using a clean lint free cloth. Re-

assemble the Accelerator. Replace the top chamber

drain plug using new thread sealant.

7. Remove the Accelo–Check Body, Item #19, Fig. 1,

and gently lift the Accelo–Check Diaphragm Assem-

bly, Item #22, Fig. 1, to verify venting of the middle

chamber. Carefully reinstall these parts.

8. Partially open Valve A, Fig. 2, gently purging any

water which may be in the trim lines. Close Valve A.

Re- place Plugs B and E, Fig. 2. Partially open Valve

A and gently purge. Close Valve A and replace the

body drain plug at the lower section of the Accelera-

tor, Item #3, Fig. 1.

9. Pressurize the Accelerator by opening Valve A, Fig.

2. Open Valve C and check for leakage at the Ball

Drip Valve D, Fig. 2. The top chamber pressure of the

Accelerator should equal the system pressure.

10. Slightly open the main water supply control valve.

Close the main drain valve when water flows, then

fully open the main supply valve. The system is now

ready for service.

Fig. 7

Loading...

Loading...