EN

FAQ - English

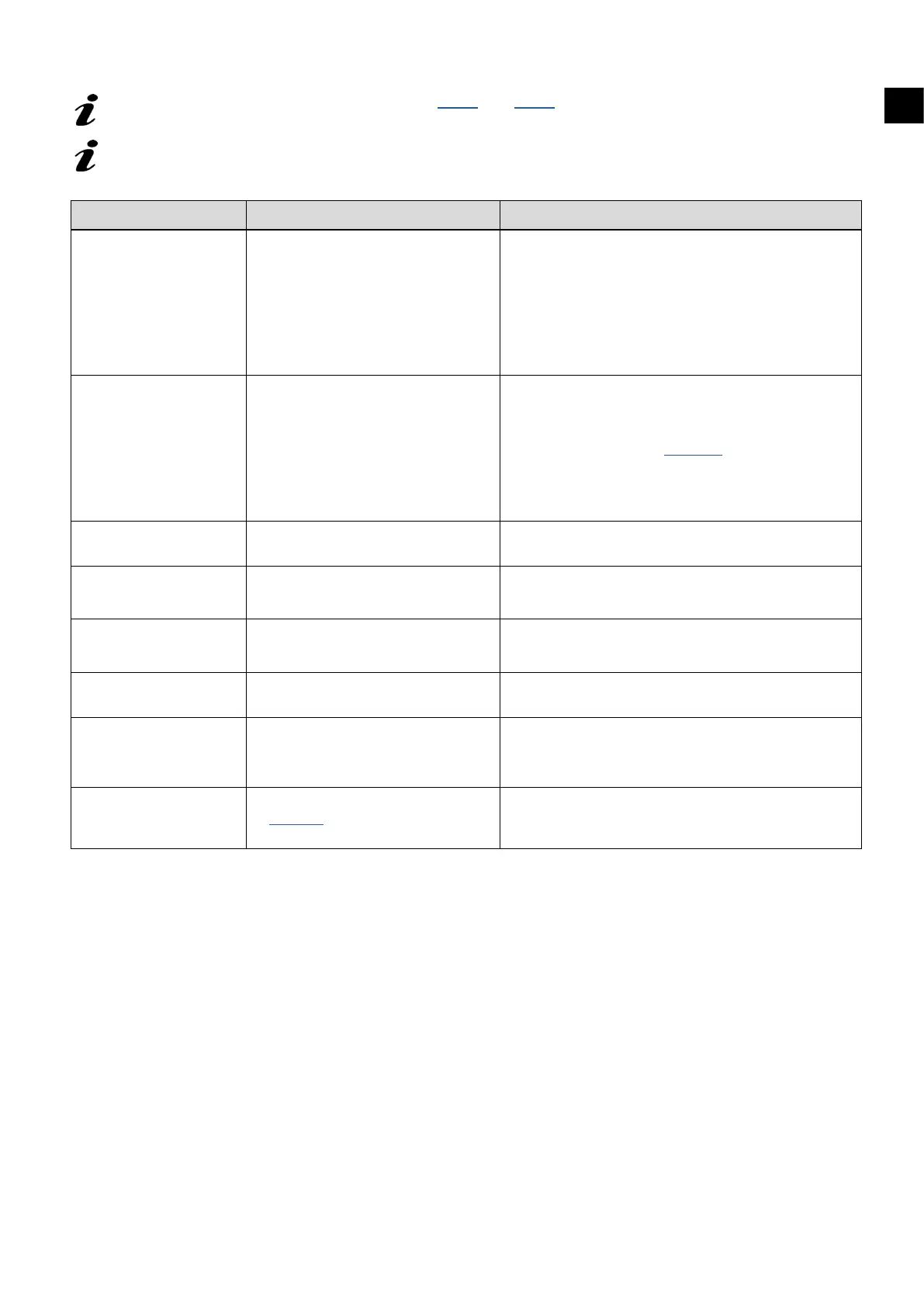

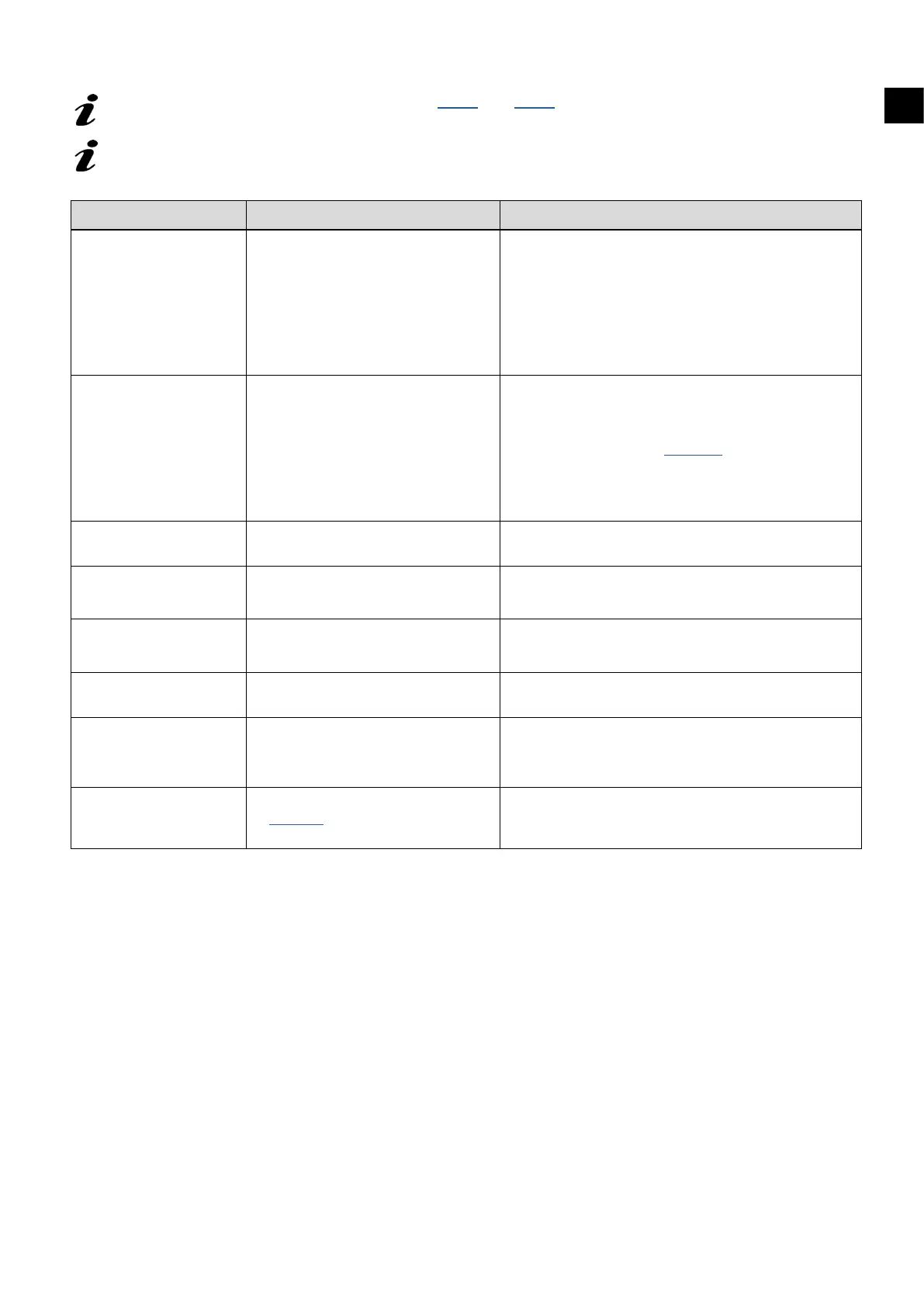

For information on operating elements, see Fig. 1 and Fig. 2 on page 2 of this document.

For chapter indications, refer to the complete instruction manual on the internet.

Problem Possible cause Corrective action

No air and no abrasive. • Blasting nozzle blocked at the hand-

piece.

• Foot switch connecting lines kinked.

• Tank selection switch in an interme-

diate position.

• Unscrew the nozzle from the hand-piece and blow it

out.

• With the nozzle removed, blow out the blasting hose

by activating the foot pedal.

• Inspect / correct the connection lines.

• Turn the switch until you feel it click into place.

Only air, no or very

little abrasive.

• The dosage nozzle in the mixing

chamber is blocked due to contami-

nated or moist sand.

• Mixing chamber lter combination

blocked.

• Abrasive contains impurities or is

moist.

• Cleaning the dosing nozzle, see chapter 6.5.

• Change lter cartridge (17, Fig. 1) (wrench SW14).

• Replace the abrasive.

Pressure control can-

not be adjusted.

• The pressure control button is

locked.

• Pull the pressure control button upwards to unlock.

Unit blasts continu-

ously.

• Foot switch connected incorrectly.

• Valve in foot switch is defective.

• Inspect / correct the foot switch connection.

• Replace foot switch.

Lamp is not alight. • Power cord not plugged in.

• Illumination defect.

• Plug the power cord into the wall outlet.

• Change light using the service or see spare part list.

Compressed air leaking

from the foot switch.

• Pneumatic hoses reversed. • Reverse the connections.

Foot switch fails to

switch on.

• No pressure at the compressed air

connection.

• Pneumatic hoses are kinked.

• Inspect the compressed air lines and/or the compres-

sor.

• Reposition the hoses.

Foot switch hoses can-

not be disconnected

from the unit.

• Push-in connection is not released

(Fig. 2 / 3).

• Press the push-in connection ring on the hose side

rmly while pulling on the hoses.

- 1 -

Loading...

Loading...