Adjustment

Nut

Closed

Open

Fig. 8 Opening and Adjusting a Quick Release

Step 2: Front Wheel & Front Fender Installation

2.1 Installing the Front Wheel

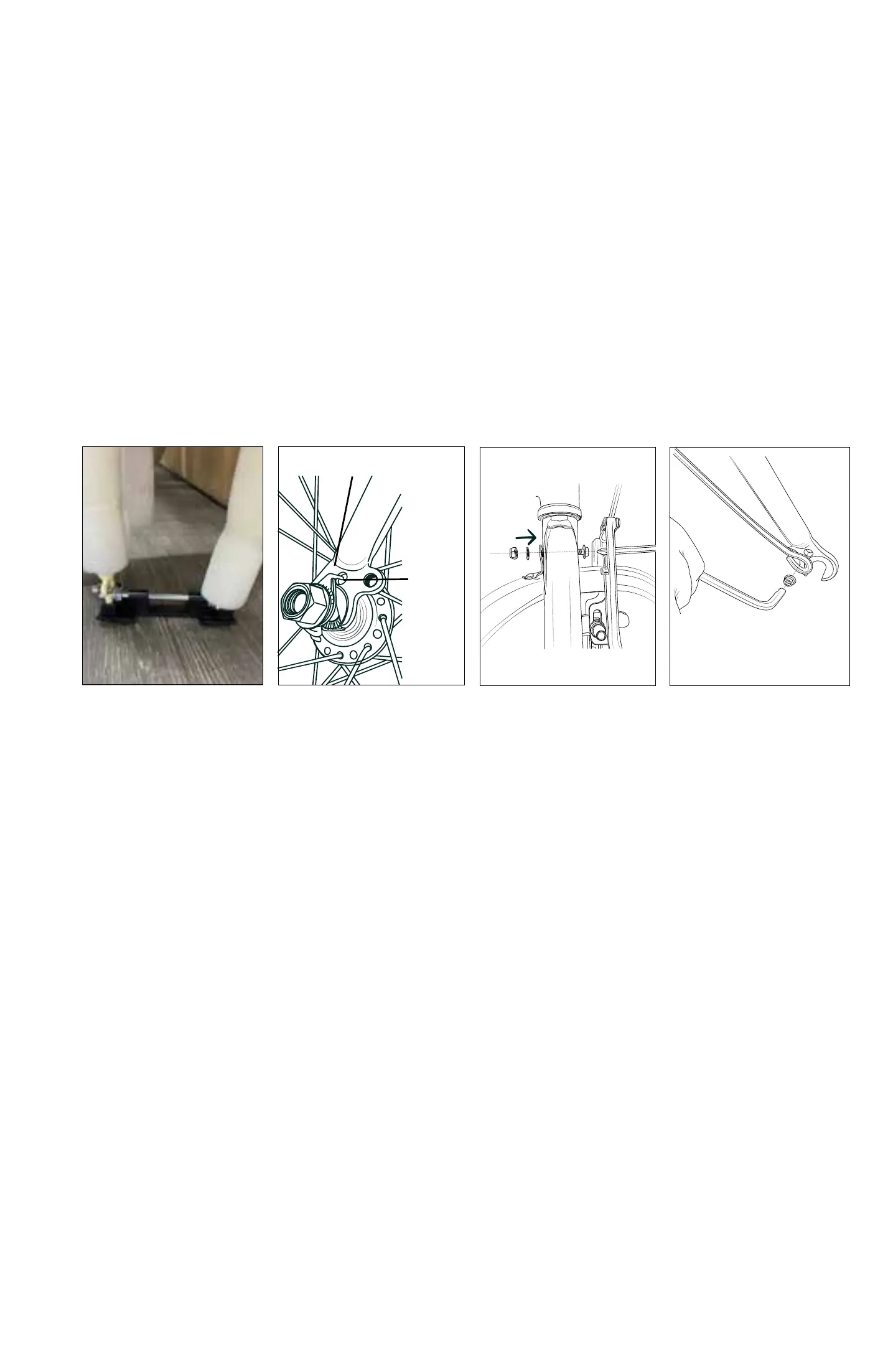

1. Remove the plastic dropout protector from the metal shipping axle. (Fig. 6)

2. Unscrew and remove the metal shipping axle from the fork dropouts. use photo

attached. You can discard or save this device in case you ship or transport your bike

with the front wheel removed. Suggest you inate the tire to make centering the wheel

in the fork easier (point 4 below).

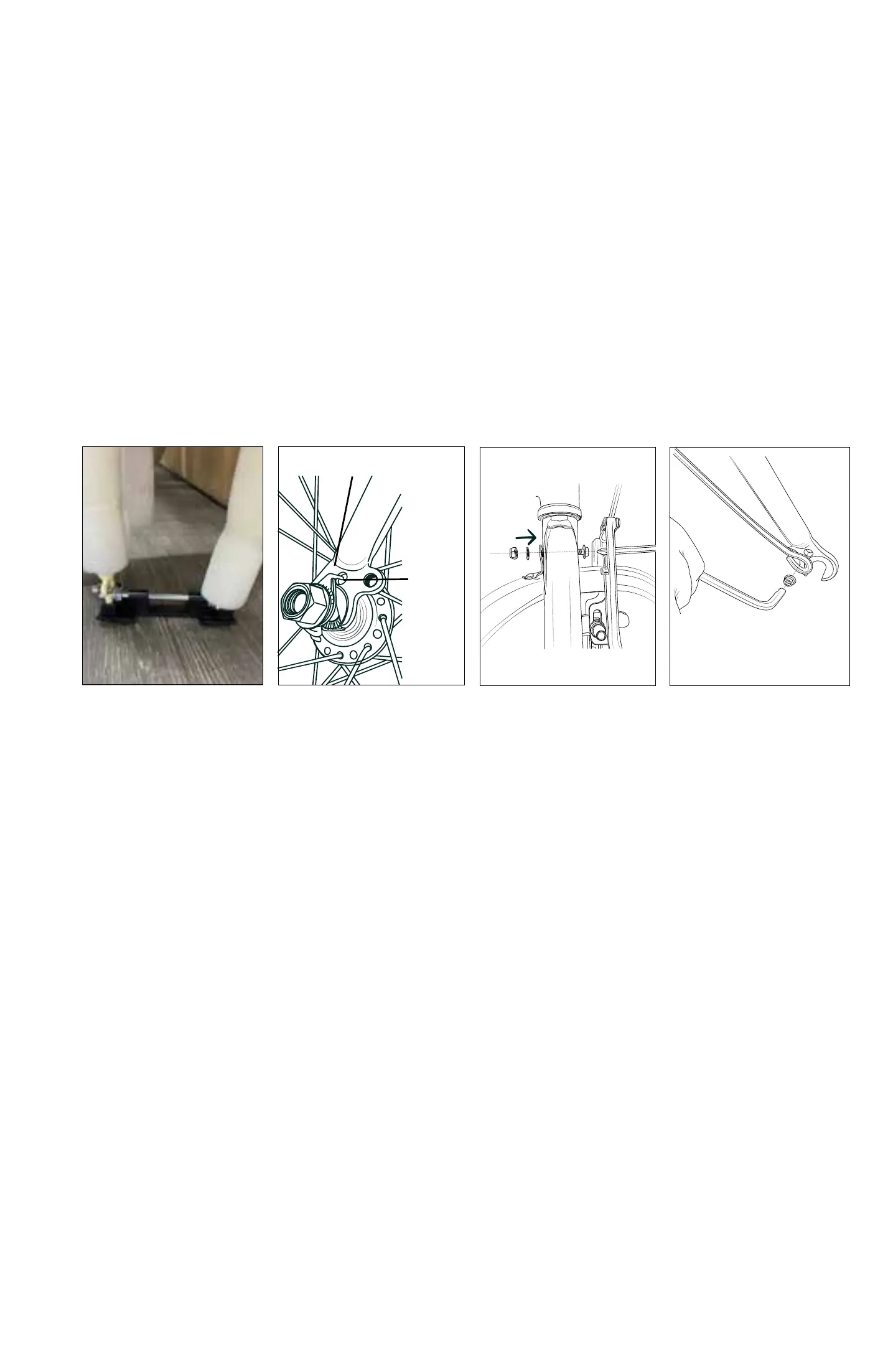

3. Loosen the axle nuts on the front wheel. Lift the front of the bike and insert the front

wheel into the fork dropouts (a helper can make this easier). Insert the tab of the safety

washers into the small holes on the outside of the fork dropouts. (Fig. 7)

4. Inspect the wheel to make sure it is centered in the fork. Tighten each axle nut a

little at a time (15mm or adjustable wrench), alternating between sides, until each axle

nut is properly tightened.

2.2 Installing the Front Fender

1. Locate the long bolt, washer, and nut which will either be in the parts bag/box or

inserted in the top of the fork.

2. Slide the fender in place from the back of the fork. Insert the long bolt through the

top/center fork hole from the front of the bike. At the rear of the fork hole, place the

bolt through the fender mounting tab with the washer and nut. While pushing the

fender tab up as far as it will go, tighten the bolt and nut to secure the fender to the

top of the fork (Fig. 8)

3. Position the fender braces to the mounting holes on the fork dropouts. It’s okay to

squeeze inward as these braces are designed to be pliable. Partially thread the screw

through the fender brace end hole and into the dropout - repeat for the other side.

When both braces are partially attached, tighten the brace screws to complete the

install (Fig. 9)

4. If the fender is not straight, or rubbing the tire, that’s okay! As mentioned above, the

fender braces can be bent to center the fender. Gently adjust the fender by hand until

it’s straight.

NOTE: Rear Fender Adjustment: The rear fender is installed at the factory and should

be good-to-go. However, it may require some small adjustment due to shipping. Follow

2.2 step 4 to straighten as necessary or a combination of loosening the brace end

bolts, retightening, and centering.

Fig. 6

Fig. 7

Fig. 9

Fig. 8

Tip of Seat

Seat Clamp

Seat Post

Seat Tube

Seat Clamp Nut

Minimum

Insertion Line

Top Tube

Seat Post Binder

Bolt and Nut

Fig. 7 Seat Assembly

Fig. 10

WARNING! The seat post must be inserted into the seat tube at a depth where the

release lever. The tightness of the

lever is adjusted by rotating the

adjustment nut opposite the quick

release lever. Turn the nut by hand to

adjust the tension while holding the

lever stable.

Fig. 11

Safety Washer

Fork

Dropout

Small Hole

7 8

minimum insertion line is not visible!

3.2 Inserting the Seat/Seatpost Assembly Into the Frame Seat Tube, Quick-Release

Seatpost Clamp:

1. Open the seat post quick release lever (Fig.11). Insert the seat post into the seat tube

to sucient depth so that the minimum insertion line is no longer showing.

NOTE: The lever should require some force to close. If it closes too easily and does not

hold the seat post in place, or if the eort to close the clamp is too great, adjust the

clamping force by loosening or tightening the adjusting nut on the side opposite the

lever.

2. When you are satised with the height of the seat post, close the seat post quick

Step 3: Seat Assembly (Refer to Fig. 10)

3.1 - Assembling the Saddle onto the Seatpost:

1. Loosen the seat clamp nuts - both sides equally.

2. Insert the seat post into the seat clamp. Make sure the seat post is rm against the

seat clamp limit.

3. Re-tighten the seat clamp nuts equally on both sides (hand tight).

4. Insert the seat post into the frame seat tube and rotate the seat until the tip of

the seat is directly above and in-line with the top tube of the frame. You can nish

tightening the seat now or after Step 3.2. Do not sit, or test saddle until completing

Step 3.2!

Loading...

Loading...