Thomas

®

XTSR52 Installation and Maintenance

(Page 7 of 13) Sizes 494-5258

CP3-002

September 2017

Supersedes 09-2016

Rexnord

5555 S. Moorland Rd., New Berlin, WI 53151-7953

Phone: 262-796-4060 Fax: 262-796-4064 www.rexnord.com

Table 3 – Set Screw Tightening Torque

5. Straight Bore with Interference Fit

5.1 Accurately measure the bore and shaft diameters to assure proper fit.

5.2 Install the key(s) in the shaft.

5.3 Heat the hub in an oven until the bore is sufficiently larger than the shaft.

5.4 275°F (135°C) is usually sufficient for carbon steel hubs. Do not exceed 400°F (205°C).

5.5 With the hub expanded, install it quickly on the shaft to the desired axial position. A pre-set axial stop device can be helpful.

6. Taper Bore

6.1 Check for acceptable contact pattern between the hub and the shaft.

6.2 Put the hub on the shaft, keeping the keyways (if existing) aligned.

6.3 Lightly tap the face of the hub with a soft mallet. The resultant position will provide a starting point for the hub axial draw up.

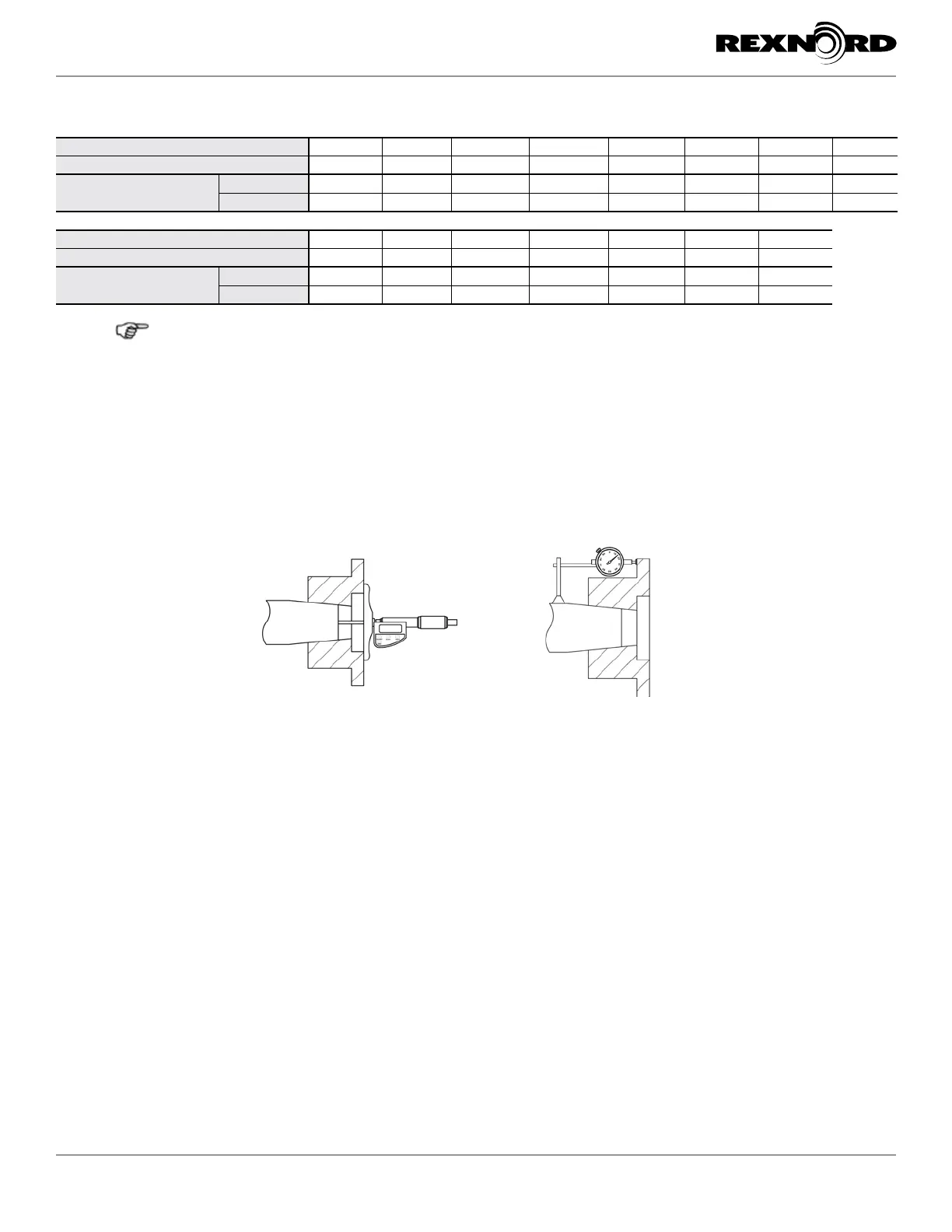

6.4 Use a depth micrometer to measure the distance from the shaft end to the hub face, as shown in Figure 5. Record the dimension.

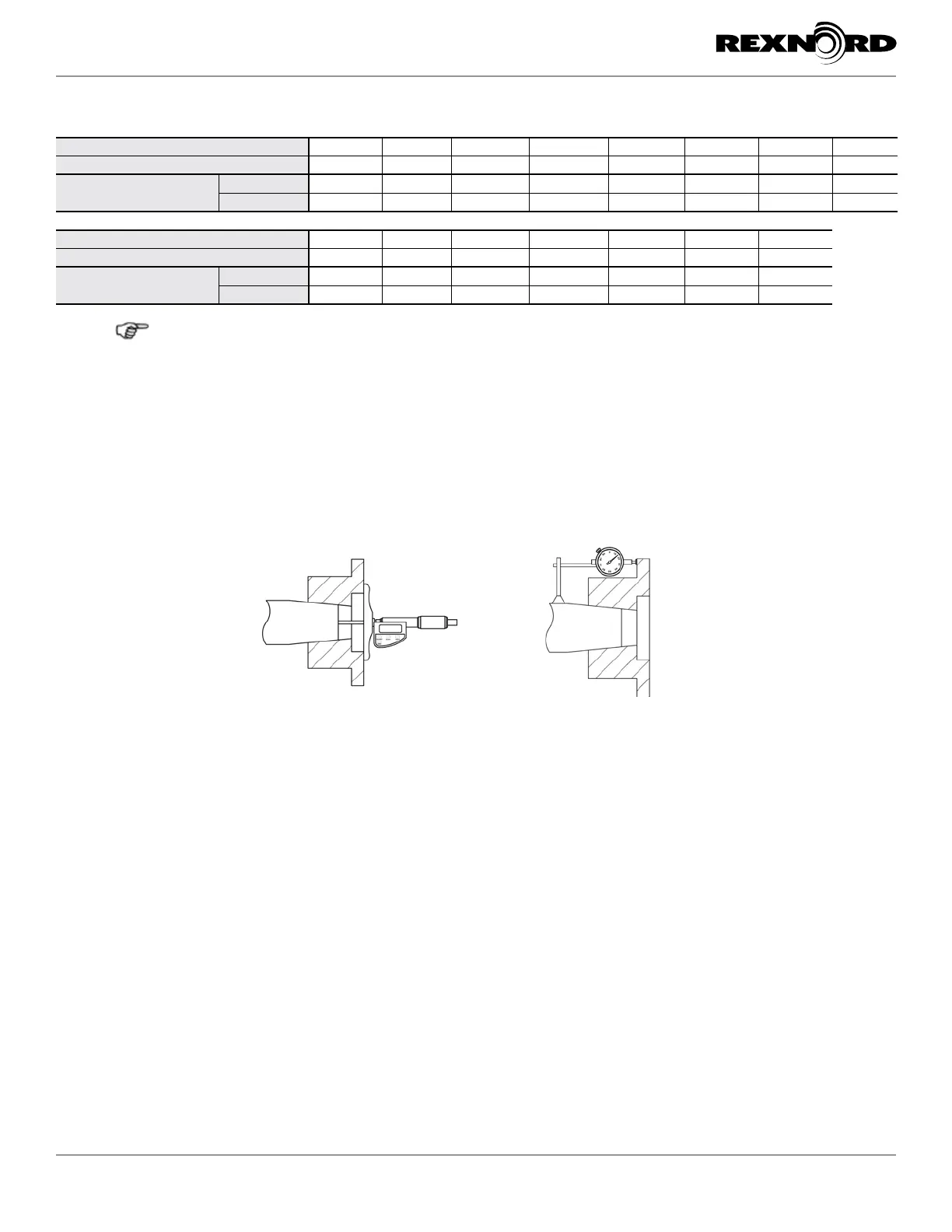

6.5 Mount a dial indicator to read axial hub advancement, as shown in Figure 6. Alternatively, the indicator can be positioned to contact the end of the

hub. Set the indicator to “zero.”

6.6 Remove the hub and install the key(s) in the shaft.

6.7 Heat the hub in an oven until the bore is sufficiently larger than the shaft.

6.8 350°F (177°C) is usually sufficient for carbon steel hubs. Do not exceed 500°F (260°C).

6.9 Higher temperatures may be required for higher interference fit levels where alloy steel hubs may be encountered. A general rule to consider is that for

every 160°F increase in temperature, steel will expand 0.001 inch for every inch of shaft diameter (or 0.029 mm/100°C). When calculating tempera-

tures, also consider additional expansion to provide clearance and allow for a loss of heat and subsequent shrinkage during the handling process.

6.10 With the hub expanded, install it quickly on the shaft to the “zero” set point. Continue to advance the hub up the taper to the desired axial position,

as defined by Rexnord’s customer. Use the indicator as a guide only. A pre-set axial stop device can be helpful.

6.11 Inspect the assembly to verify that the hub is properly positioned. Consult Rexnord if necessary.

6.12 Install hub axial retention device (if any) in accordance with the equipment manufacturer’s specifications.

Set Screw Size

1/4-20 1/4-28 5/16-18 5/16-24 3/8-16 3/8-24 1/2-13 1/2-20

Hex Head Key Size

1/8 1/8 5/32 5/32 3/16 3/16 1/4 1/4

Tightening Torque

(Nm)

7 9 15 16 27 31 68 75

(lb-in)

66 76 132 144 240 276 600 660

Set Screw Size

M6 M8 M10 M12 M16

1/4 3/8

Hex Head Key Size

3 4 5 6 8

1/8 3/16

Tightening Torque

(Nm)

6 12 25 50 100 8 25

(lb-in)

55 110 220 440 880 70 220

Figure 5 –

Shaft end to hub

face measurement

example.

Figure 6 –

Dial indicator

placement for axial

draw measurement

example.

CAUTION! Never use two set screws with one on top of the other in the same tapped hole.

Loading...

Loading...