69

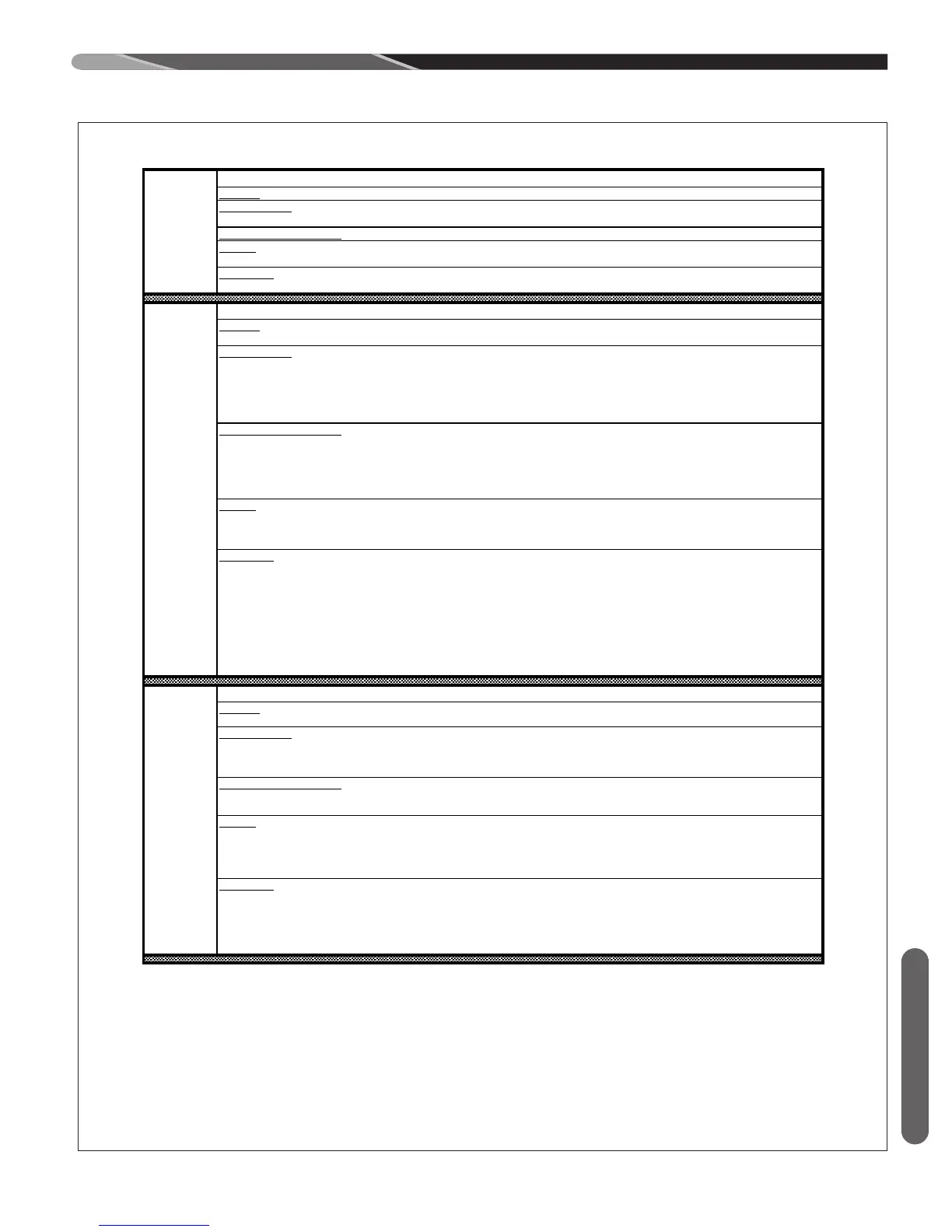

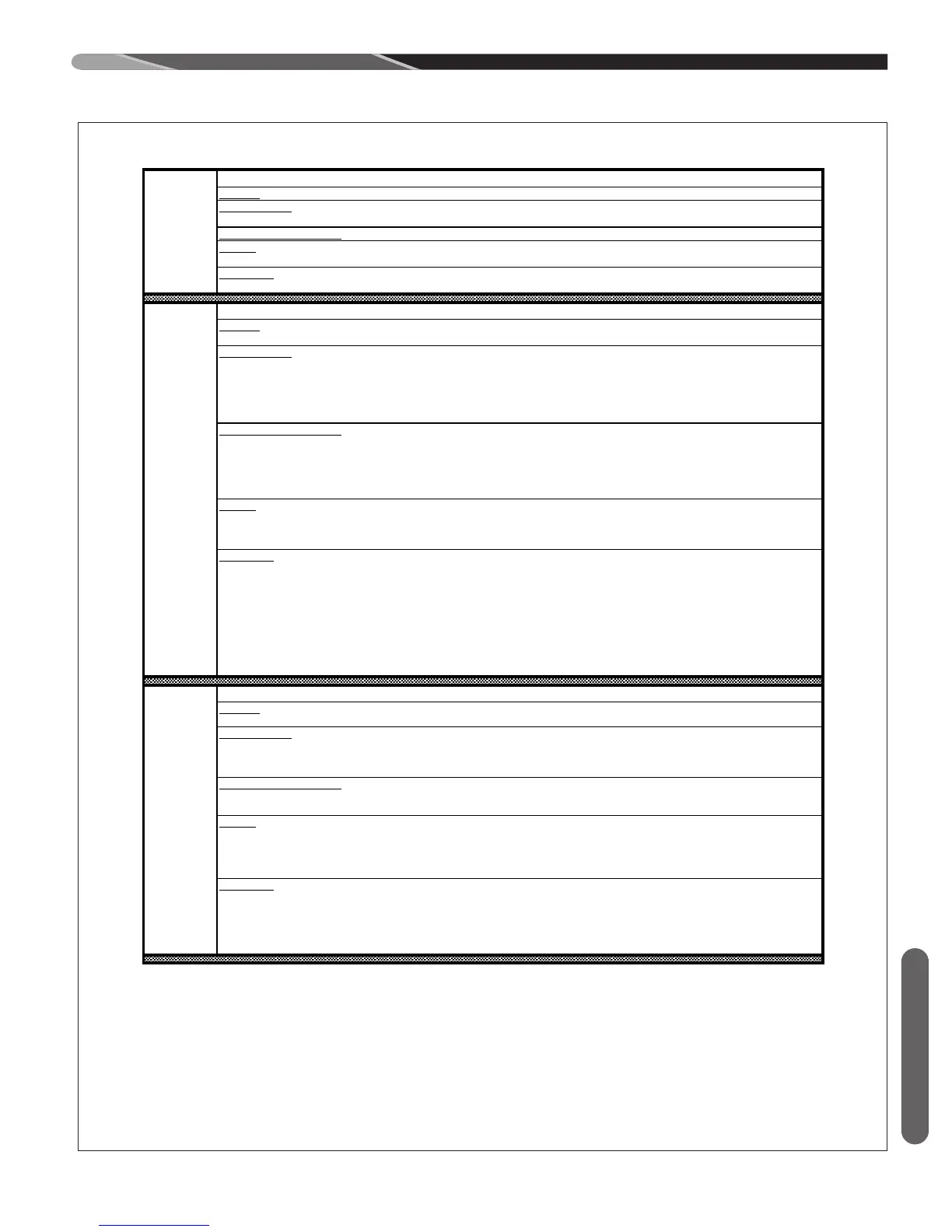

TABLE 13 (continued)

802V FAULT CODES WITH DESCRIPTIONS AND SOLUTIONS

44

LOW PRESSURE SWITCH CLOSED, INDUCER OFF

STATUS: This is a critical fault. The furnace will not operate in gas heat modes but all other modes (e.g. cooling) should

function if present simultaneously with a heating call (e.g. defrost call in dual-fuel mode)

.

DESCRIPTION

: The low pressure control (or switch) should not be closed when the inducer is not running. If it is, this is a sign

of a serious condition. The switch may be welded closed or purposely bypassed in

the field. Before any heat cycle can begin,

the pressure switch is tested to make sure that it is opened. The switch is ignored except in gas heating modes.

(3) Check wiring and connections. Replace and/or repai

r as necessary.

CAUSE

:

(1) Faulty switch.

(3) Loose or faulty wiring.

(4) Abnormally high negative pressure present on vent system without inducer running.

SOLUTION

:

(1) Insufficient venting through either the inlet or exhaust.

(2) Check wiring and connections. Replace and/or repair as necessary.

OVER-TEMPERATURE SWITCH (ROLL-OUT) OPEN (AKA MRLC)

STATUS: This is a critical fault. The furnace will not operate in gas heat modes but all other modes (e.g. cooling) should

function.

DESCRIPTION

: The Manually Reset Limit Control (M.R.L.C.) is also known by the name "Rollout Limit". There can be several

on any given furnace. When one or more of these limits open, they must be manually pushed bac

k to the closed position

(hence the name; Manually Reset) to force the acknowledgement of a critical fault. This fault will occur when flames have rolled

out of the normal area in the heat exchanger and into the burner

compartment. This fault should rarely (if ever) be seen in the

field and indicates a very serious problem that must be repaired before furnace operation can continue.

(1) Check that the pressure switch(es) have not been we

lded closed or bypassed. Check that the inducer is operating at the

proper rpm. Insure that the venting does not exceed the maximum specified lengths. Check for obstructions in combustion

venting. Check that all gaskets between the inducer and center

panel / heat exchanger are properly installed and sealed.

(3) Unstable flame pattern.

CAUSE

:

(2) Loose or faulty wiring.

SOLUTION

:

(1) Replace low pressure control (switch).

(4) Check for proper venting and terminations as defined in the furnace installation instructions.

33

(3) Check that all burner assembly components are properly installed. Check that all seals between the burner and blower

compartments are tight. Insure that the door seals are in place and that the burner door is properly installed and does not

leak.

Check to make sure that the heat exchanger has not been damaged; i.e.: crushed tubes, breached collector box and etc.

SOLUTION

:

Repair the short circuit condition and replace fuse.

(2) Pressure switch physically bypassed in the field.

(2) Remove bypass and restore correct operation. Determine reason for bypass (e.g. vent length too long) and correct issue.

Not

ify homeowner and proper authorities of illeagle tampering if necessary.

30

DESCRIPTION: The fuse has been opened. This usually occurs when there is a 24VAC short to common or ground on the low-

votage side of the transformer.

EXPECTED OPERATION

: The fault code is displayed and no other operation can take place.

CAUSE

:

An electrical short from low voltage (24VAC) to ground or common has occurred.

OPEN FUSE

STATUS: This is a critical fault. The furnace will not operate in any mode.

EXPECTED OPERATION

: When the MRLC (Manually Reset Limit Control) circuit has been opened, the IBM (Indoor Blower

Motor) is energized at maximum heating speed. The gas valve circuit is de-energized (if it was energized)

and the IDM (Induced

Draft Motor) is energized at high speed. Response to thermostat cooling calls will take place as normal with IBM energizing at

the higher of the two blower speeds (high heat or cool) when

a call for cooling is also present. When the fault is cleared, the

IDM will remain energized for a 20 second post-purge and the IBM will remain energized for the user-selected blower off-delay

period.

EXP

ECTED OPERATION: There will be no other operation than displaying of the fault code and diagnostic messages to the

homeowner and technician. The fault code is only present during a heat call before pre-purge begins.

Loading...

Loading...