72

Diagnostics

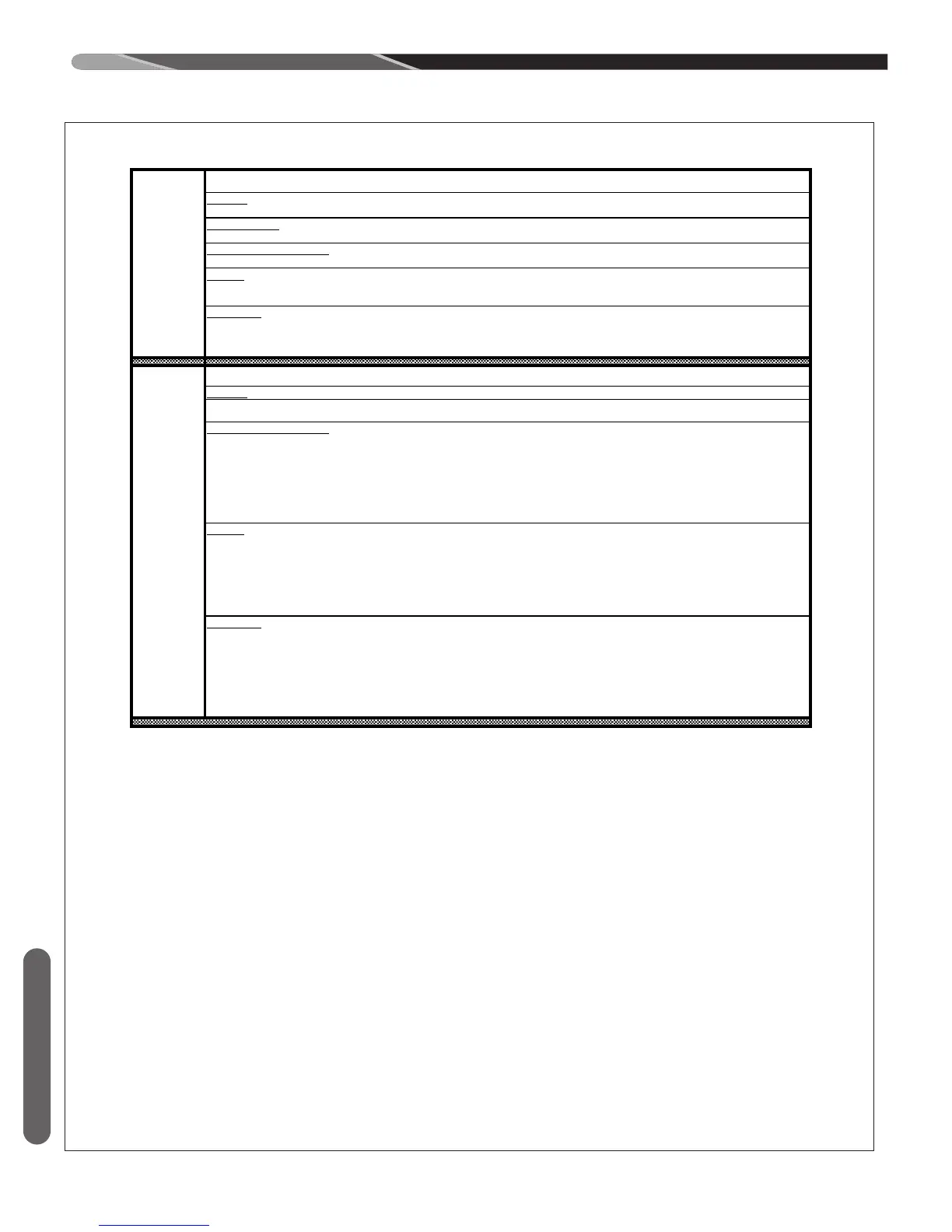

TABLE 13 (continued)

802V FAULT CODES WITH DESCRIPTIONS AND SOLUTIONS

BLOWER FAULT - MOTOR CANNOT RUN

STATUS: This is a critical fault. The furnace will not operate in any mode.

(1) The static pressure is too high because the ductwork is improperly designed or is restricted for some other reason or the

filter needs cleaning

or replacing. Remove the obstruction or repair the duct so that static pressure does not exceed published

values in the specification sheets or installation instructions.

(1) The blower has hit the maximum speed or

torque limit specified by the manufacturer or is running at the temperature limit

because the static pressure is too high.

CAUSE

:

SOLUTION

:

60

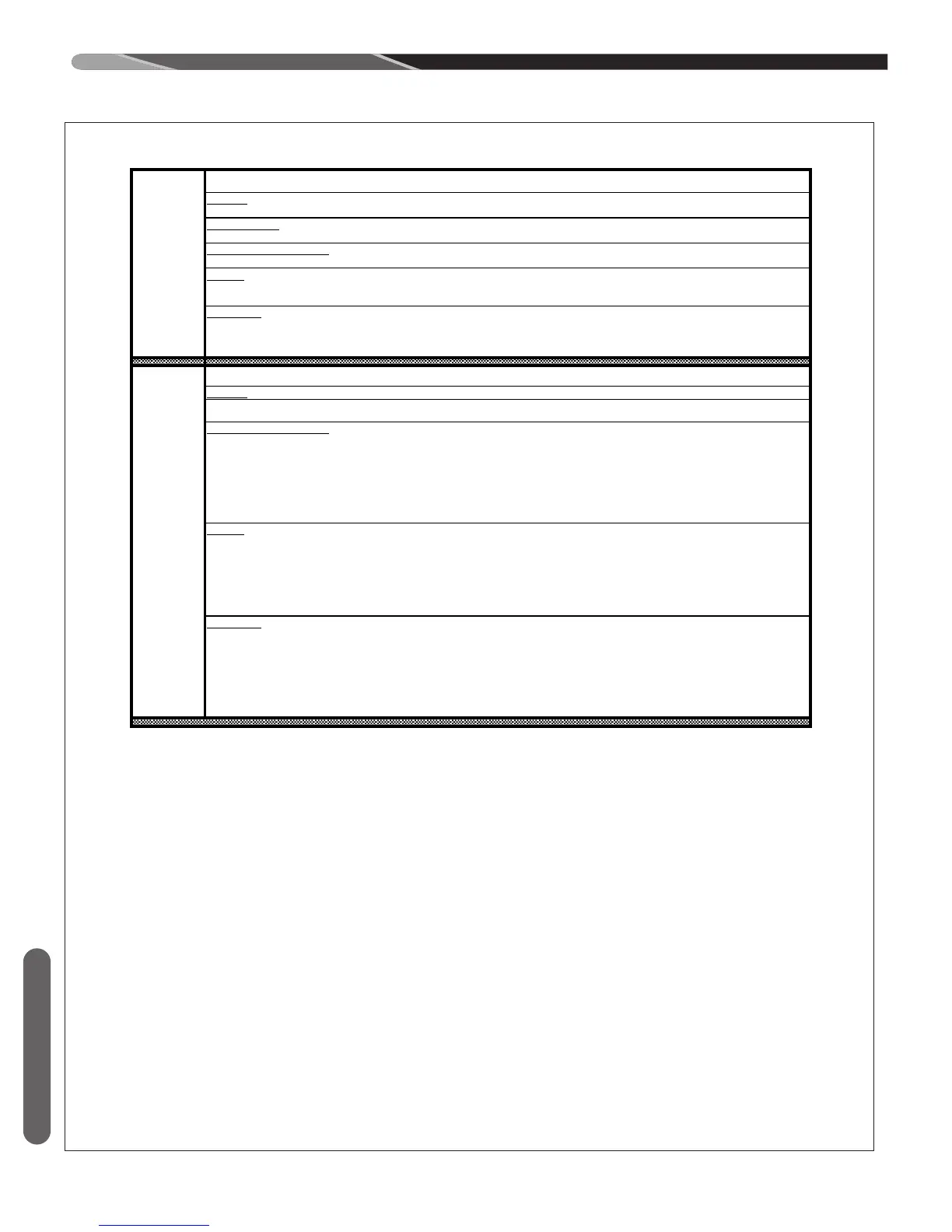

BLOWER FAULT - BLOWER CAN STILL RUN

(2) Replace the Power Factor Correction choke.

(1) Remove obstruction or replace motor.

61

SOLUTION:

(6) The motor has failed catastrophically.

(3) The furnace model data is faulty or corrupted.

(3) Replace the furnace memory card with the correct replacement part from ProStock.

EXPECTED OPERATION

: All (including thermostat) operation should continue as normal. Blower operation may be slightly

compromised but will continue.

STATUS

: This is a non-critical fault experienced by the furnace. All operations (including thermostat calls) should continue as

normal with no perceivable difference in operation.

DESCRIPTION

: A blower fault which is non-critical allows the blower to continue to run but at less-than-optimal conditions.

(6) Replace the motor.

(4) Wiring to the motor and/or P.F.C. has become

compromised.

(4) Inspect and replace or repair wiring and/or connectors to the motor and/or P.F.C. as necessary.

(2) The motor Power Factor Correction (P.F.C.) choke is faulty and needs replacing.

CAUSE

:

(5) The blower wheel has become damaged or is not properly attached to the motor shaft.

(5) Replace the blower wheel and/or attach the blower wheel to the motor shaft properly.

(1) The motor has tripped on thermal limit because of

a restriction or bearing failure.

EXPECTED OPERATION

: If the furnace was in heating operation when this fault occurred, blower operation will immediately

stop and the furnace will shut down normally with post-purge at the correct speed. After the post purge (or immediately if no

heat call was present), no other operation (including thermostat calls) will occur until this fault is cleared.

This fault may be displayed in heating or cooling modes and may also be displayed in

heating mode after the main limit control

has been opened four times consecutively for more than 150 seconds (2m:30sec) each time. If this happens, the IFC

determines that the motor and/or blower is not functional and enters a hard

lockout condition requiring repair of the blower/motor

and manual reset of power to the furnace.

Loading...

Loading...