35

INSTALLATION INSTRUCTIONS

Venting

Recommended Vent Lengths

Before starting the vent installation, careful planning

should be given to the routing and termination of the

vent pipes. The length of the vent pipes (air intake and

exhaust) should be kept to a minimum. Also, see pages

38–39 and 45 for vent terminal placement. Refer to the

maximum and minimum vent length charts for the pipe

sizes that can be used and the total equivalent length of

pipe that can be used. Do not exceed equivalent length

of pipe in maximum vent length chart.

Maximum Vent Length (airintake/exhaust) each:

Number of

90° Elbows

Maximum Length

of 2" Straight Pipe

Maximum Length

of 3" Straight Pipe

Maximum Length

of 4" Straight Pipe

1 5.0 ft. (1.5 m) 38.0 ft. (11.6 m) 94.0 ft. (28.7 m)

2 3.5 ft. (1.0 m) 36.5 ft. (11.1 m) 88.0 ft. (26.8 m)

3 2.0 ft. (0.6 m) 35.0 ft. (10.6 m) 82.0 ft. (25.0 m)

4 Not available 33.5 ft. (10.2 m) 76.0 ft. (23.2 m)

5 Not available 32.0 ft. (9.8 m) 70.0 ft. (21.3 m)

6 Not available 30.5 ft. (9.3 m) 64.0 ft. (19.5 m)

The system will not operate if there is excessive

restriction (pressure drop) in the venting system. Use

the chart above to calculate the maximum pipe run

length with the required number of elbows (e.g., a

maximum 38 ft. [12 m] of 3" vent pipe may be used

provided there is only one 90° elbow in the system).

A 90° elbow is equivalent to 1 ft. 6 in. (0.5 m) of 2" or 3"

straight pipe, and to 6 ft. (1.8 m) of 4" straight pipe. A

45° elbow is equivalent to 9” (0.25 m) of 2" or 3" straight

pipe, and to 3 ft. (0.9 m) of 4" straight pipe.

The vent termination does not count as part of the straight

pipe equivalent when determining the total vent length.

Minimum Vent Length:

Number of

90° Elbows

Minimum Length

of 2" or 3" Straight

Pipe

Minimum Length

of 4" Straight

Pipe

1 1.0 ft. (0.3 m) 38.0 ft. (11.6 m)

NOTICE:

To use 2" or 4" vent pipe, a reducing adapter or an

increasing adapter will be required.

WARNING:

To use Category III Stainless Steel, a proper transition part

will be required to prevent flue gas from leaking.

Depending on the size of pipe that is chosen for venting

the water heater, it might be necessary to use a fitting

for stepping down in pipe size, to connect to the water

heater.

All intake and exhaust venting components must have

the same diameter size. DO NOT use a different size

on the intake and exhaust venting.

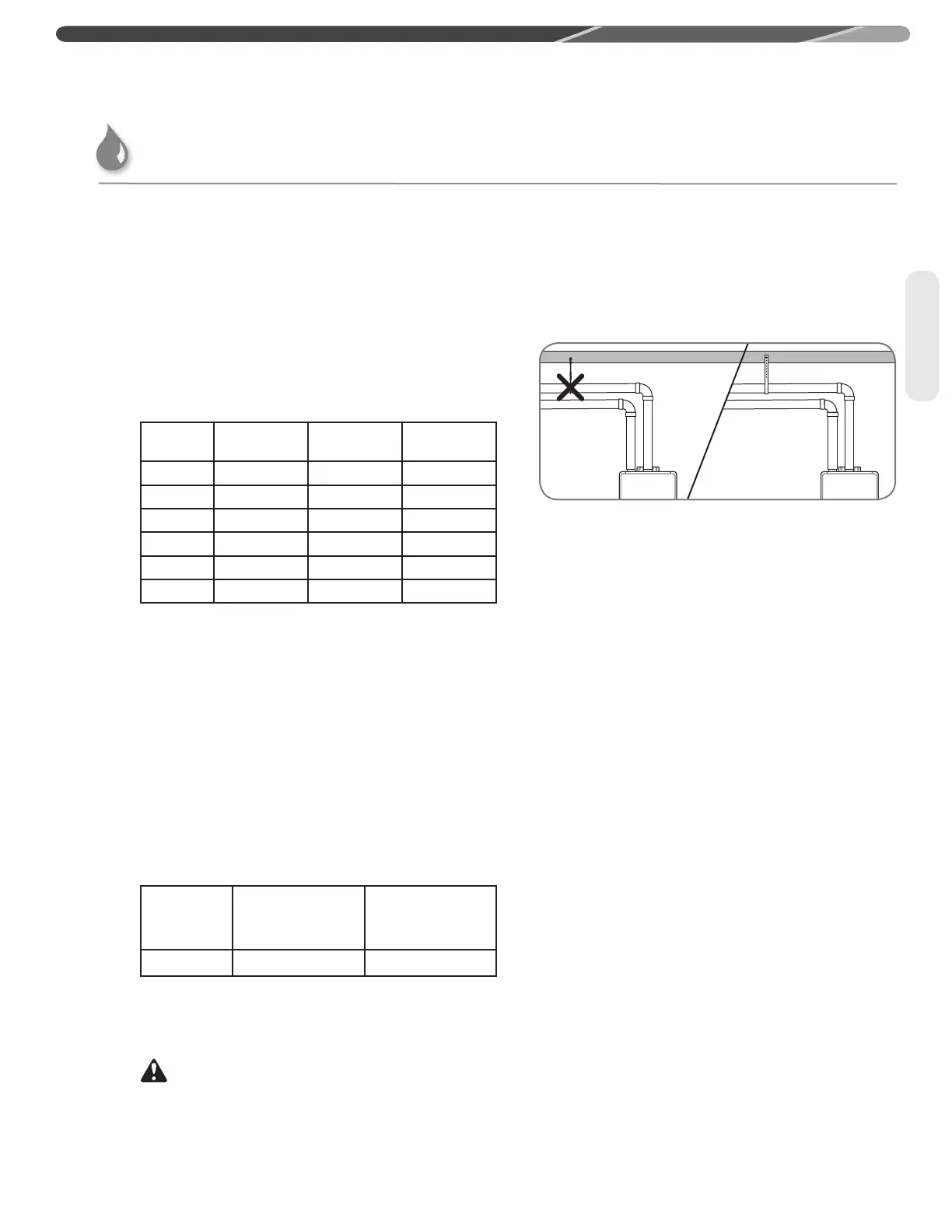

The unit may be vented horizontally through a wall

or vertically through the roof. Pipe runs must be

adequately supported along both vertical and horizontal

runs. Maximum unsupported span is recommended

to be no more than 4 feet (1.2 m). It is imperative

that the first hanger be located on the horizontal runs

immediately adjacent to the first 90-degree elbow from

the vertical rise. Only use support isolation hanging

bands. DO NOT use wire to support pipe runs.

Stress levels in the pipe and fittings can be significantly

increased by improper installation. If rigid pipe clamps

are used to hold the pipe in place, or if the pipe cannot

move freely through a wall penetration, the pipe may

be directly stressed, or high thermal stresses may be

formed when the pipe heats up and expands. Install

accordingly to minimize such stresses.

Venting for Direct-Vent Water Heater

Loading...

Loading...