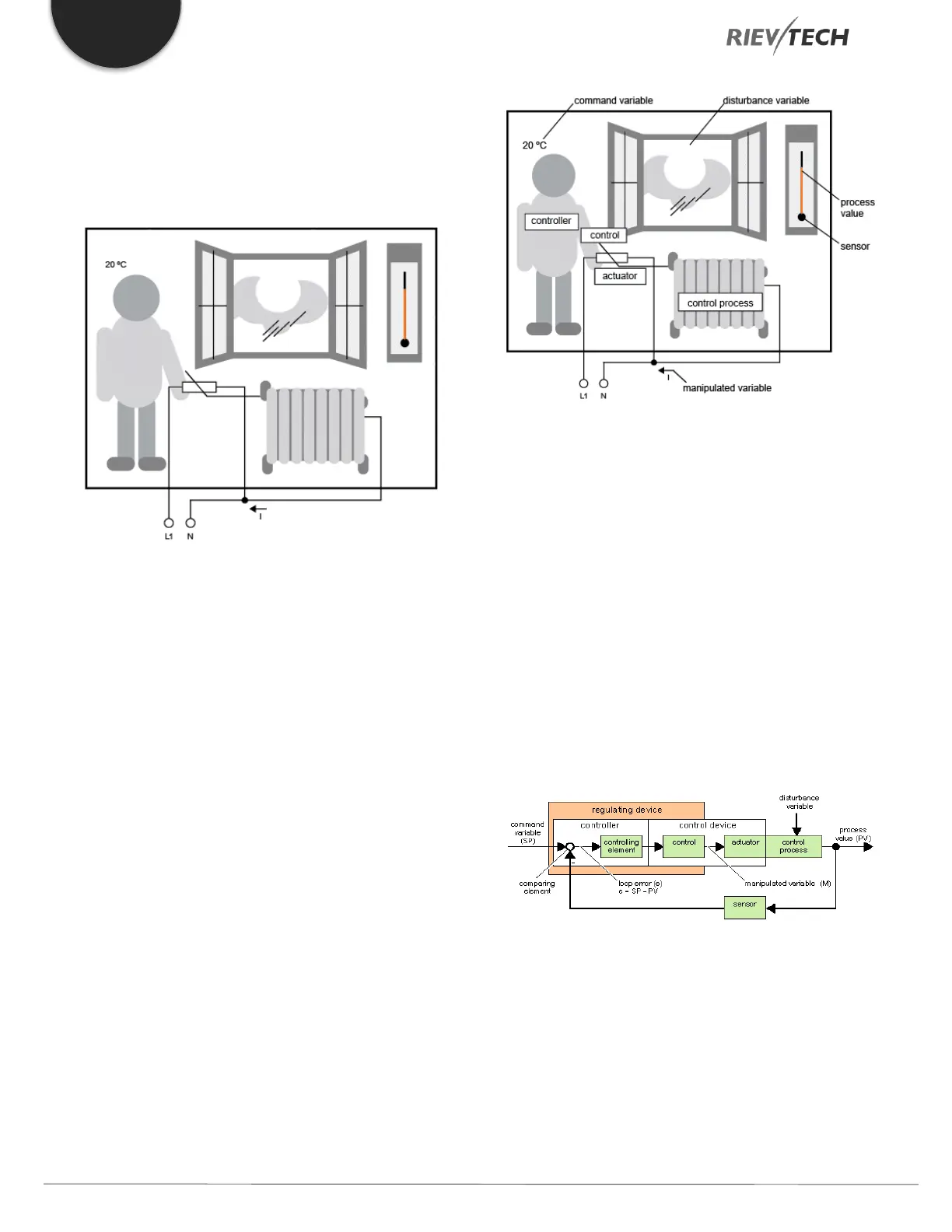

In the example below, regulating means that the person

can increase the heat output if the room temperature

drops to below 20 °C. If the room temperature rises above

20 °C, the heat output is reduced.

Basic concepts of regulating

In the example, the current for the electric heating is the

manipulated variable. The changeable resistance is the

actuator. The hand that operates the actuator is the

control. The actual room temperature is the controlled

variable or the process value. The desired room

temperature is the command variable or the setpoint value.

The electric heating is the control process. The

thermometer is the sensor. The temperature loss from

opening the window is the disturbance variable.

So, this means that the person measures the process value

(room temperature) with the sensor (thermometer),

compares the process value (room temperature) with the

command variable (desired room temperature) and uses

the actuator (changeable resistance) to manually regulate

the manipulated variable (heating current), in order to

compensate for the disturbance variable (temperature

drop from opening the window). The person is, therefore,

the controller.

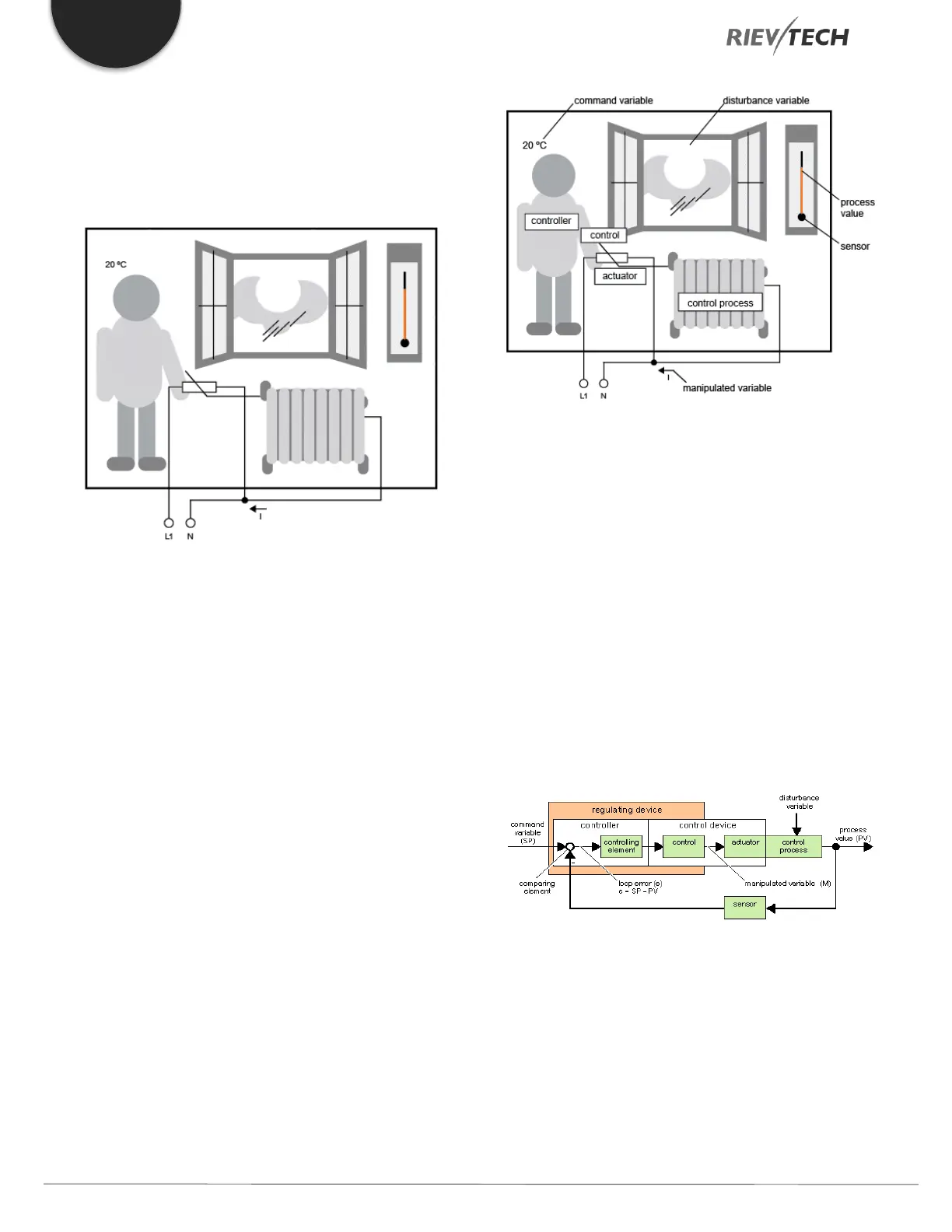

The control device is formed from the actuator and the

control.

The control and controller together form the regulating

device.

The following picture gives an abstract portrayal of the

situation described above.

The comparing element uses the sensor to compare the

command variable with the process value. If the command

variables and process value deviate from one another, this

results in a positive or negative loop error that in turn

changes the process value.

Control loop

The process value x influences the manipulated variable M

by means of the regulating device. This creates a closed

circuit that is also known as a control loop.

If in the example above, the window is opened, the

temperature in the room drops. The person must increase

Loading...

Loading...