3.1 test switching

Test switching may only be carried out if the control elements are mounted in the main valve body,

otherwise mechanical damages could result.

ATTENTION: closing cap (1) must be removed from the valve stem (5, 52, 60) for test switching and during

normal operation (screw off cap immediately after re-engagement).

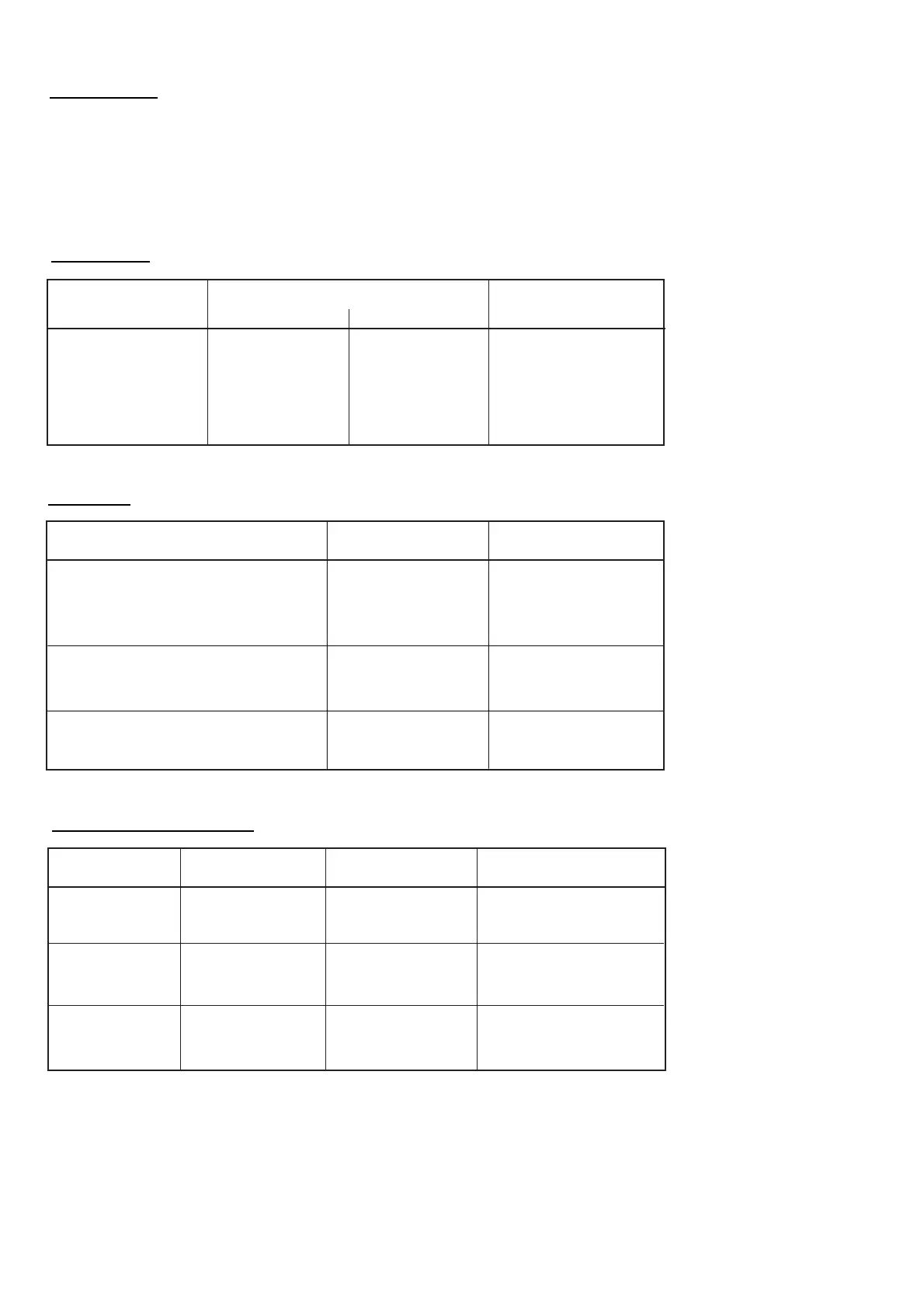

screw item no.

torque M

A

in Nm

remarks

K 1a

K 2a

10

33

109

131

12

-

25

65

12

20

15

65

version PN 63

version PN 100

3.2 torque table

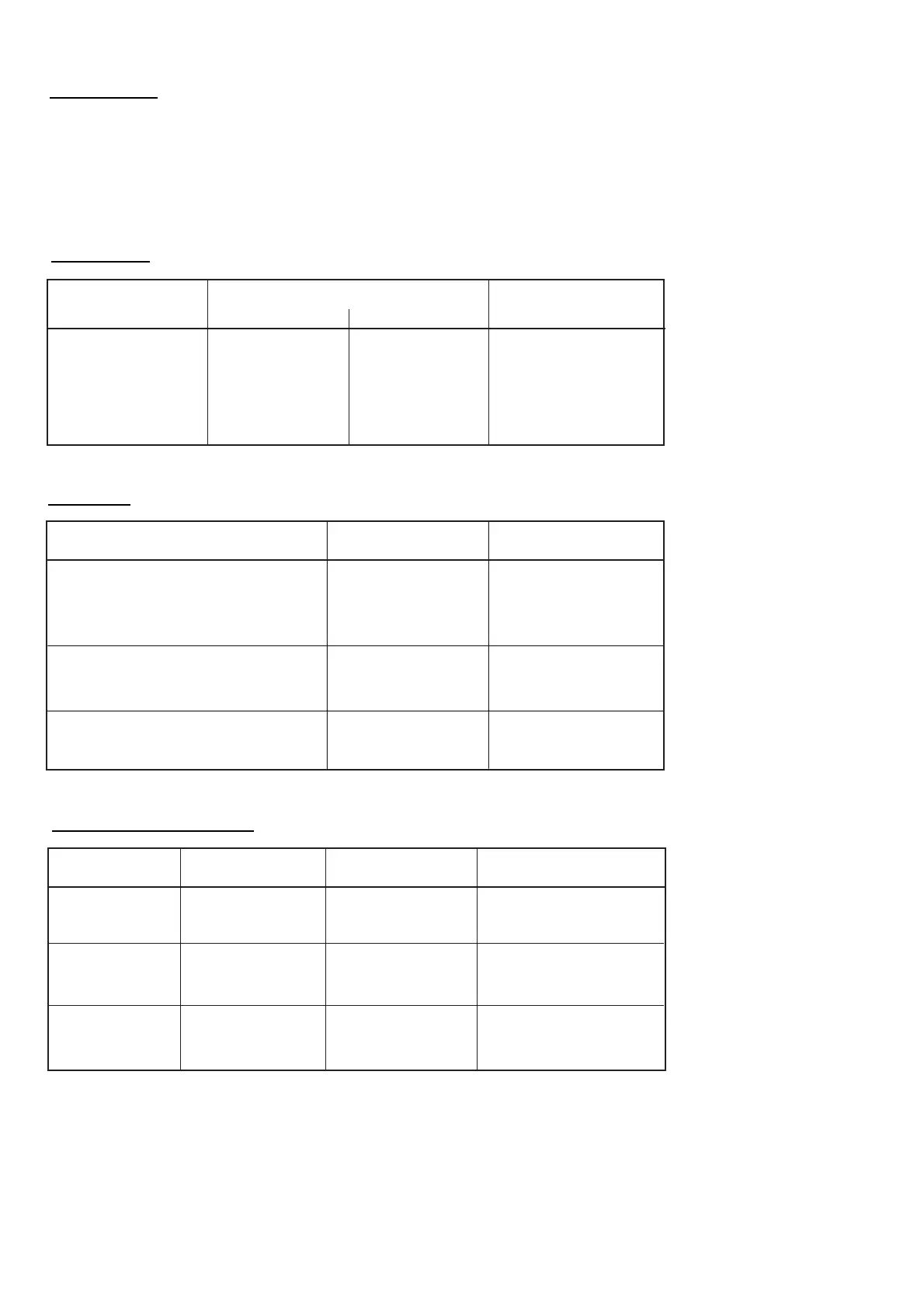

3.3 lubricants

parts (apply thinly)

all o-rings,

diaphragm clamping rim

all moving areas

thread of the valve plate (3),

thread of the closing lid (1, 107)

all screws and screwed pipe connections

lubricant

silicone grease

assembly paste

high duty grease

RMG stock no.

00 027 081

00 027 091

00 027 058

3.4 assembly and adjusting tools

tool

RMG part no. for item no. remarks

tongs A 19

DIN 5254

tongs D 19

DIN 5256

SSV setpoint

adjuster

00 026 531

00 026 532

10 004 912

17

51

3 and 4

not necessary for RMG 300,

RMG 703, and RMG 704

673.20 p.4

Loading...

Loading...