720.20 S.3

Our leaflet 720.00 gives full information with technical data, different versions, and dimensions of the safety shut-off

valve (SAV) RMG 720.

Our brochure "General Operating Instructions for Gas Pressure Regulators and Safety Devices" will be useful to fit

the valve into the line, put it into service and find faults that might disturb its operation.

The construction, set-up, supervision and maintenance of gas pressure regulating stations are subject to special

national technical rules which should be strictly observed, for example those given by the German DVGW Work-

sheets G 490, G 491, and G 495.

The frequency of periodical maintenance to be foreseen for the safety shut-off valve RMG 720 should be determined

according to the prevailing service conditions and the type and composition of the gaseous medium. We, therefore,

obstain from imposing any fixed intervals and would rather refer you to the recommendations given by the DVGW

Worksheet G 495 on "Gas Pressure Regulating Stations and Metering Stations for High Gas Volumes - Supervision

and Maintenance".

For maintenance all parts are to be cleaned and subjected to a thorough visual inspection. A visual inspection should

not be omitted when the course of operation or performance tests have shown lack of response accuracy.

Particular care should be given to the checking of sealings and diaphragms, as well as all carrying and movable parts.

Damaged parts should be replaced by new ones.

The item numbers referred to in the maintenance instructions are identical with those of the spare parts drawings and

spare parts lists.

We recommend to keep all parts that are specially marked (*) in the spare parts lists in stock for prompt maintenance

availability.

2. Special operating instructions

• Opening the safety shut-off valve (SAV)

The SAV is provided with underpressure shut-off release. Re-engagement is possible only after the pressure pre-

vailing at the measuring point comes up to the service pressure p . The pressure compensation necessary for re-

opening is automatically effected by the pressure compensating valve integrated in the valve plate.

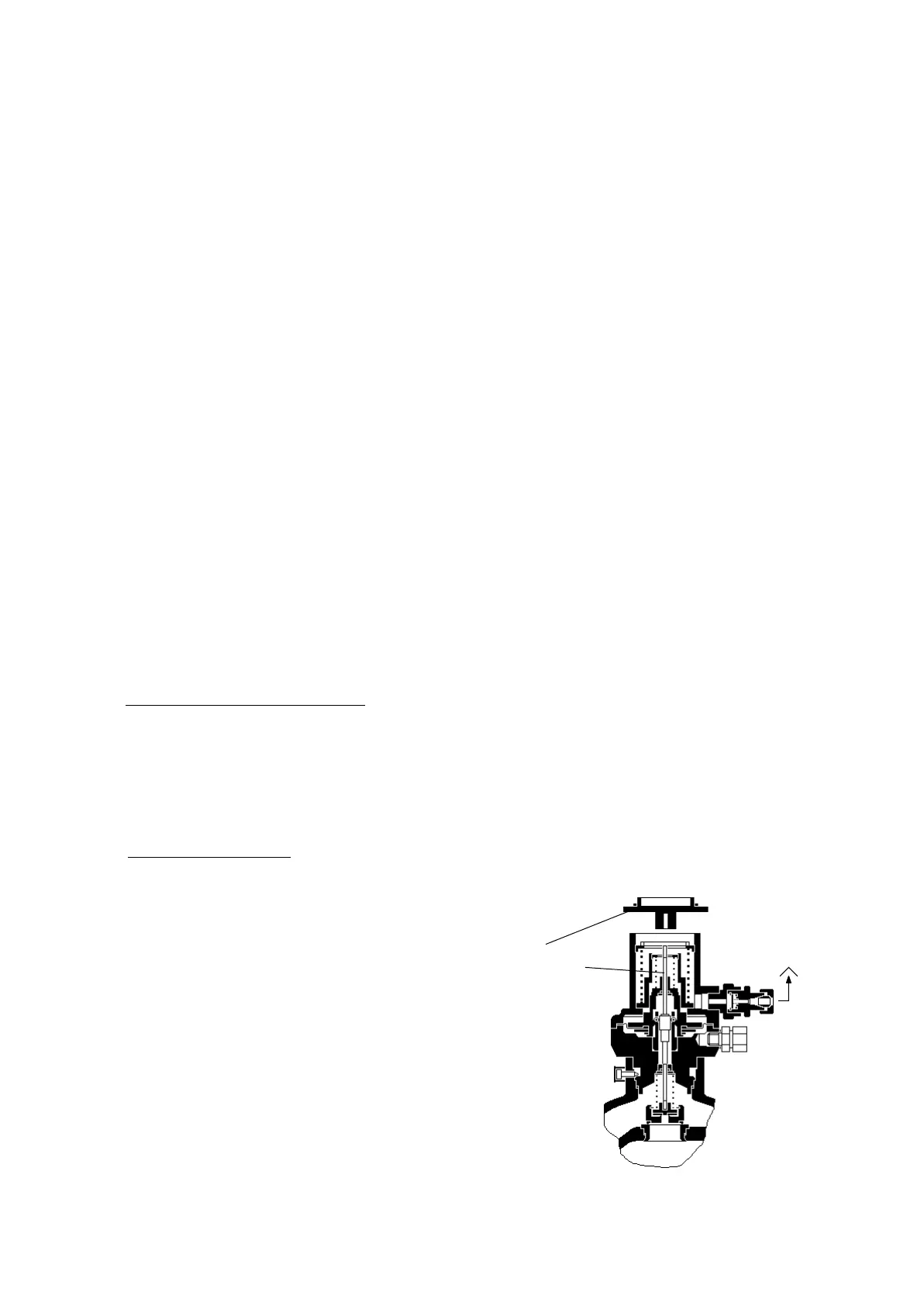

Measuring units K 1a, K 2a

(for incorporation into RMG 720 DN 25, and into RMG 300, RMG 330, RMG 332 as well as RMG 402)

Screw out locking cap (1), turn upside-down, screw

it on to valve stem and turn slowly towards body:

The pressure compensation will respond.

Pull locking cap until stop and let it go back

smoothly: The SAV is open and will re-engage.

In order to ensure perfectly reliable SAV-release

performance after re-opening, it is

to screw the locking cap back into its normal

position

a

ATTENTION

indispensable

1. General Remarks

locking cap (1)

valve stem (40, 53, 59)

Loading...

Loading...