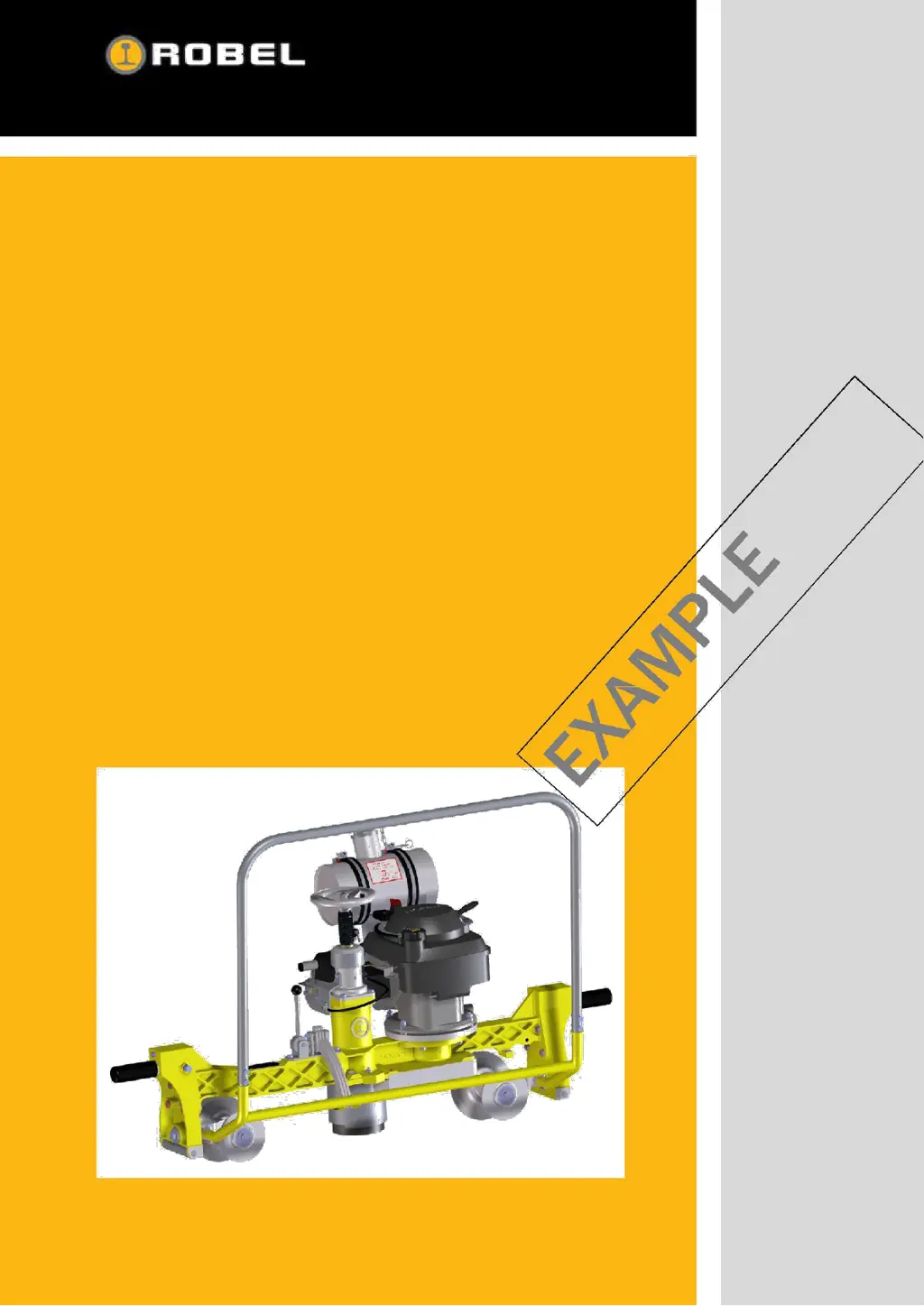

How to fix a ROBEL 13.45SKS Vers. 01 engine that won't start?

- MMariah SalasAug 12, 2025

If the ROBEL Industrial Equipment engine doesn't start, several factors could be at play. First, ensure the fuel tank is adequately filled. Next, check that the engine switch is set to the “ON” position and that the fuel tap is open. If the engine is cold, make sure to move the choke lever to the “CLOSE” position. Other potential causes include dirty carburetor jets (clean the carburetor), a problematic spark plug (maintain the spark plug as described in Ch. 7.2.4), lack of ignition spark (check cables, connections, and the ignition coil, replacing if necessary), a choked fuel filter (clean it), or a flooded engine (close the fuel tap, set the throttle lever to full throttle, start the engine; if necessary, remove, clean, and dry the spark plug).