What to do if ROBEL Industrial Equipment displays 'Maintenance necessary'?

- Aamanda75Aug 18, 2025

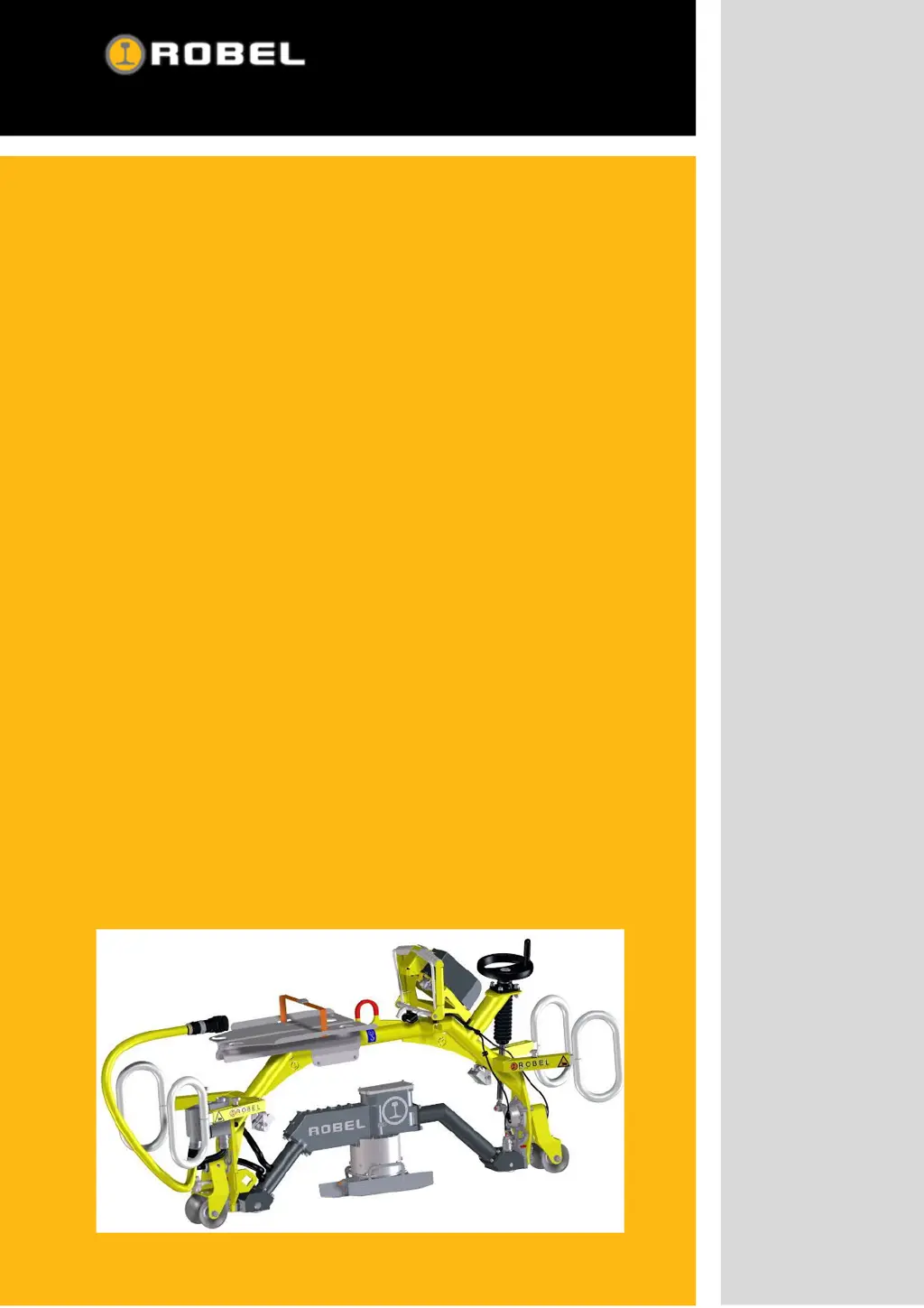

If your ROBEL Industrial Equipment displays a 'Maintenance necessary' message, it means maintenance is due or the maintenance interval has not been reset. Perform the required maintenance or reset the maintenance interval.