Customer Service Telephone 1.800.304.6563

Customer Service Facsimile 1.800.426.0804

HVACCustomerService@robertshaw.com

Robertshaw®, Ranco®, Paragon® and Uni-Line® are

trademarks of Robertshaw, its subsidiaries and/or

affiliated companies. All other brands mentioned

may be the trademarks of their respective owners.

For Technical Service

Telephone 1.800.445.8299

Facsimile 1.630.260.7294

TechnicalService@robertshaw.com

www.uni-line.com

www.robertshaw.com

©2014 Robertshaw

09/14 –1-810 RevC

WARNING

Servicing of gas controls, appliance and systems must be

performed by qualied service personnel only.

CAUTION: If control has been exposed to water in any way, it must be

replaced. If gas valve fails to shut o, do not turn o electrical power.

Turn o gas supply allowing fan or circulang pump (if so equipped) to

connue running unl system has cooled. Replace control.

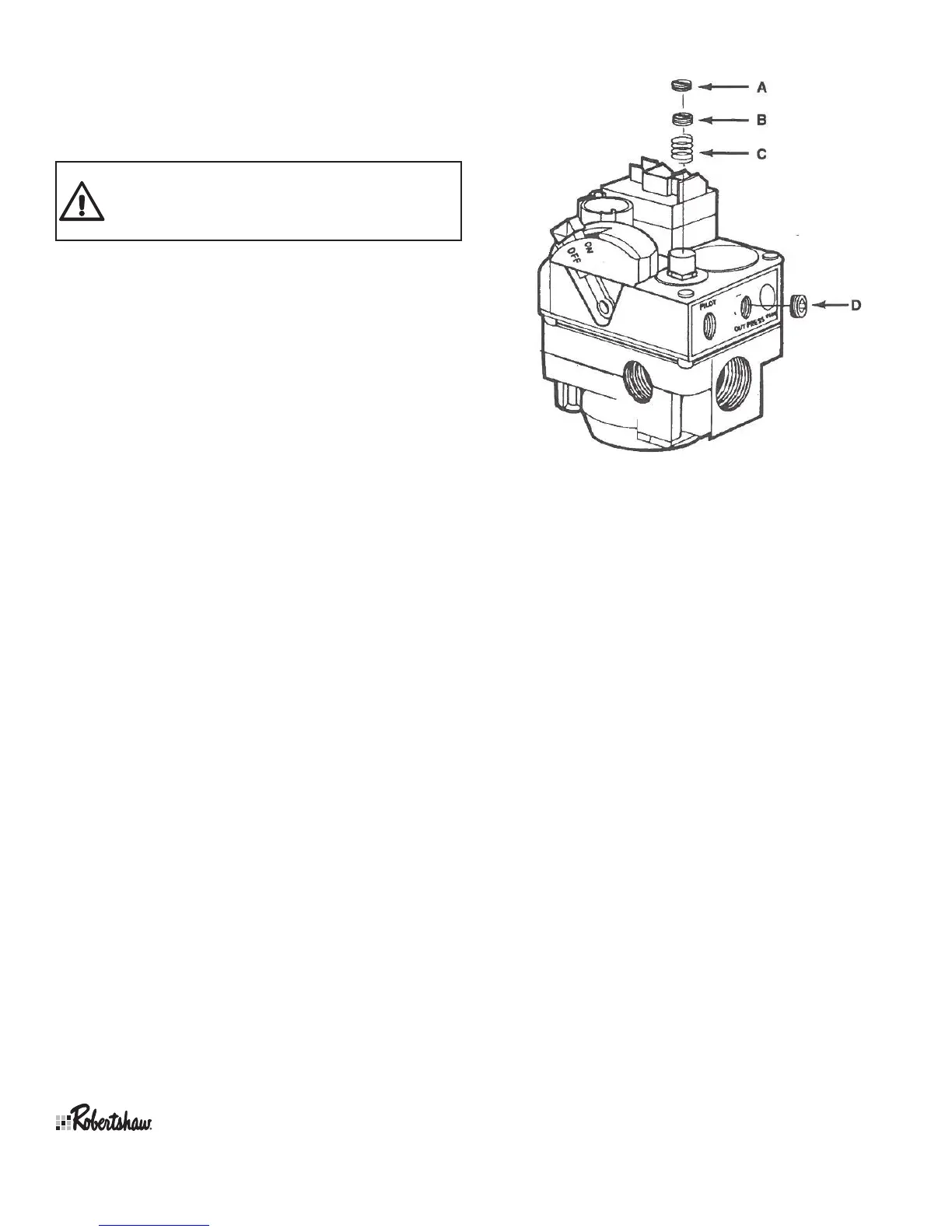

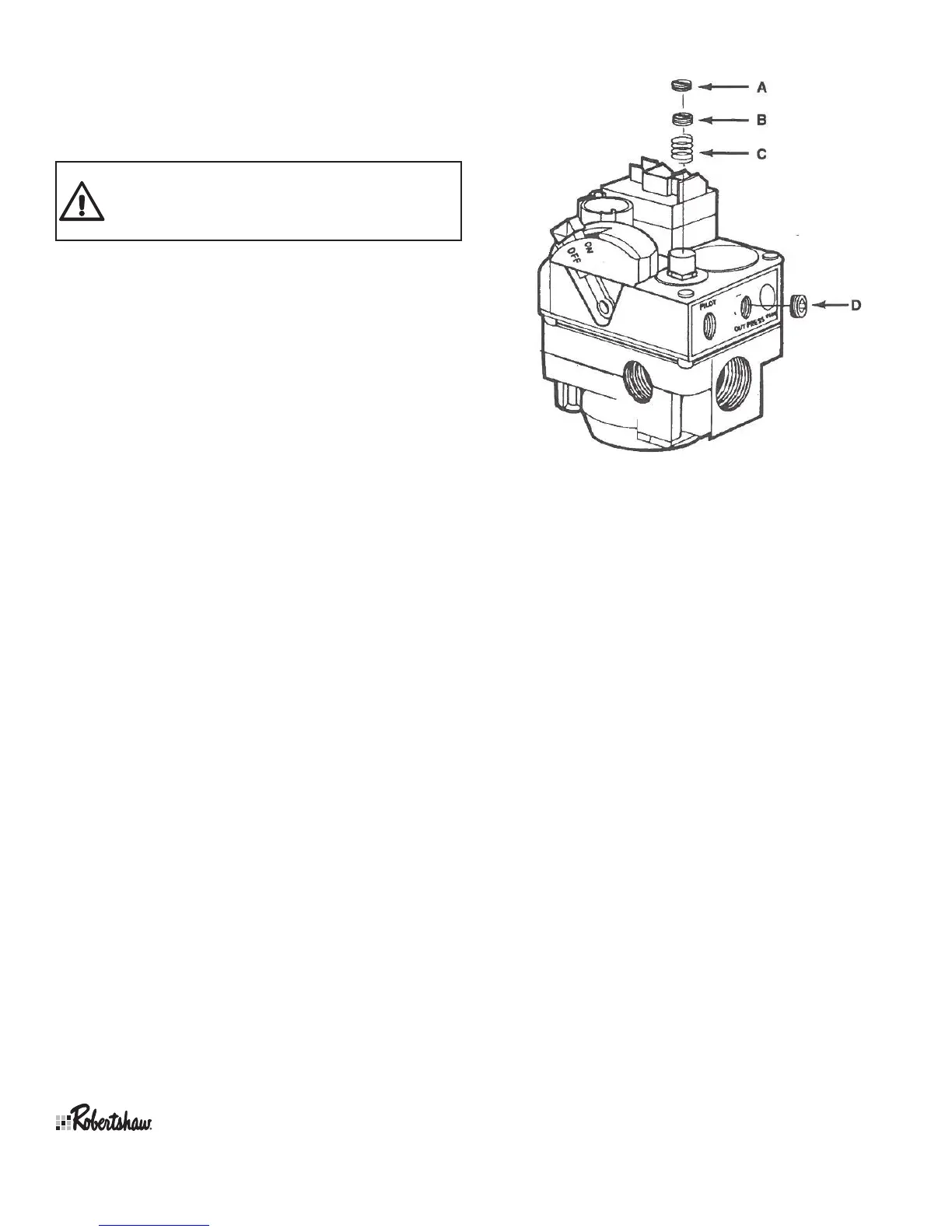

PRESSURE REGULATOR ADJUSTMENTS

Adjustment of the pressure regulator is not normally necessary since it

is preset at the factory. However, eld adjustment may be accom plished

as follows:

NOTE: Manometer aachment may be accomplished at pressure tap

plug, above control outlet, as shown in gure to the right. If using inlet

pressure tap to measure incoming pressure. See drawing on rst page.

1. Manometer or gauge aachment may be accomplished at

pres sure tap plug (D).

2. Remove regulator adjustment screw cap (top of control - A).

3. With small screwdriver, rotate adjustment screw (B) “clockwise”

to increase, or “counterclockwise” to decrease pressure to comply

with manufacturer’s specicaons.

4. Replace regulator adjustment screw cap (A).

REGULATOR CONVERSION

CAUTION: Main burner and pilot orices must be changed when

regulator is converted from one type of gas to another.

The 720 series valves can be converted from natural to L.P. by installing

the enclosed conversion kit.

1. Turn o gas and electricity to appliance.

2. Remove sloed cap (A), adjusng screw (B), and natural gas spring

not color coded - (C), from control.

3. Install new L.P. spring - color coded with a black strip.

4. Install new adjusng screw (B).

5. Aach manometer or pressure gauge at the outlet pressure tap (D).

6. Turn gas and electricity on.

7. Turn room thermostat to call for heat.

8. With burner on, adjust screw (B) to supply L.P. gas to pressure as

recommended by the appliance manufacturer.

9. If adjusng screw (B) reaches its maximum depth (booms out)

before recommended pressure seng is reached, turn screw

counterclockwise unl pressure drops slightly (approximately 0.1”

W.C.) WARNING: Do not stretch or alter spring.

10. Turn o gas and electricity to appliance.

11. Remove manometer or pressure gauge and reinstall pressure tap

outlet plug (D).

12. lnstall new red sloed cap in place of (A).

13. Turn gas and electricity on.

SERVICE INSTRUCTIONS

14. With burner operang, immediately check all ngs for leaks with

soap soluon. Bubbles indicate leaks that must be corrected.

15. Aach label to show control has been converted to L.P.

16. Set room thermostat to desired temperature.

Loading...

Loading...