Publication 520-PC001E-EN-P - September 2020 | Supersedes Publication 520-PC001D-EN-P - February 2016

Copyright © 2020 Rockwell Automation, Inc. All rights reserved. Printed in China.

Allen-Bradley, AppView, CustomView, expanding human possibility, FactoryTalk, PowerFlex, QuickView, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

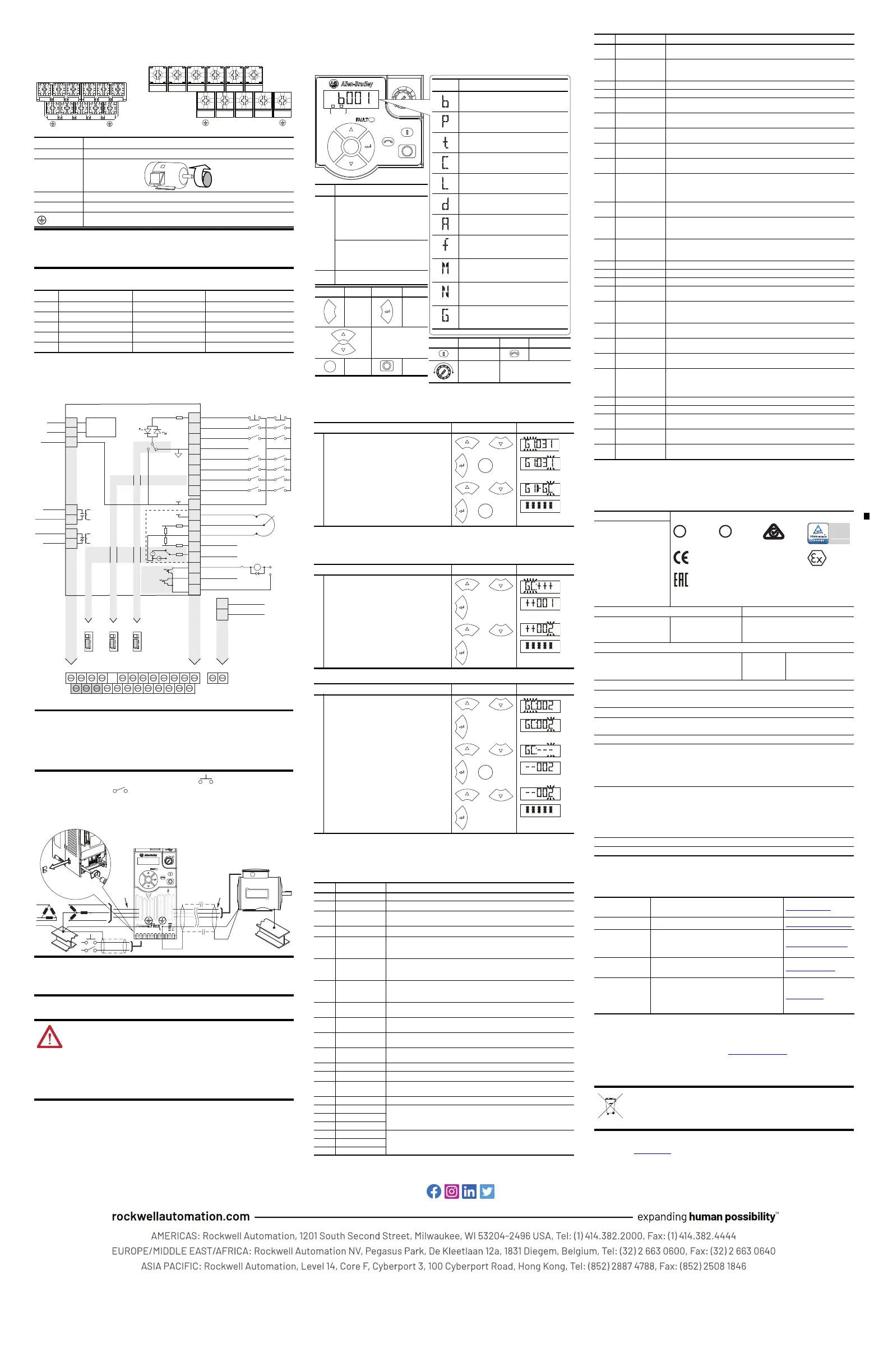

Power Terminal Block

Power Terminal Block Specifications

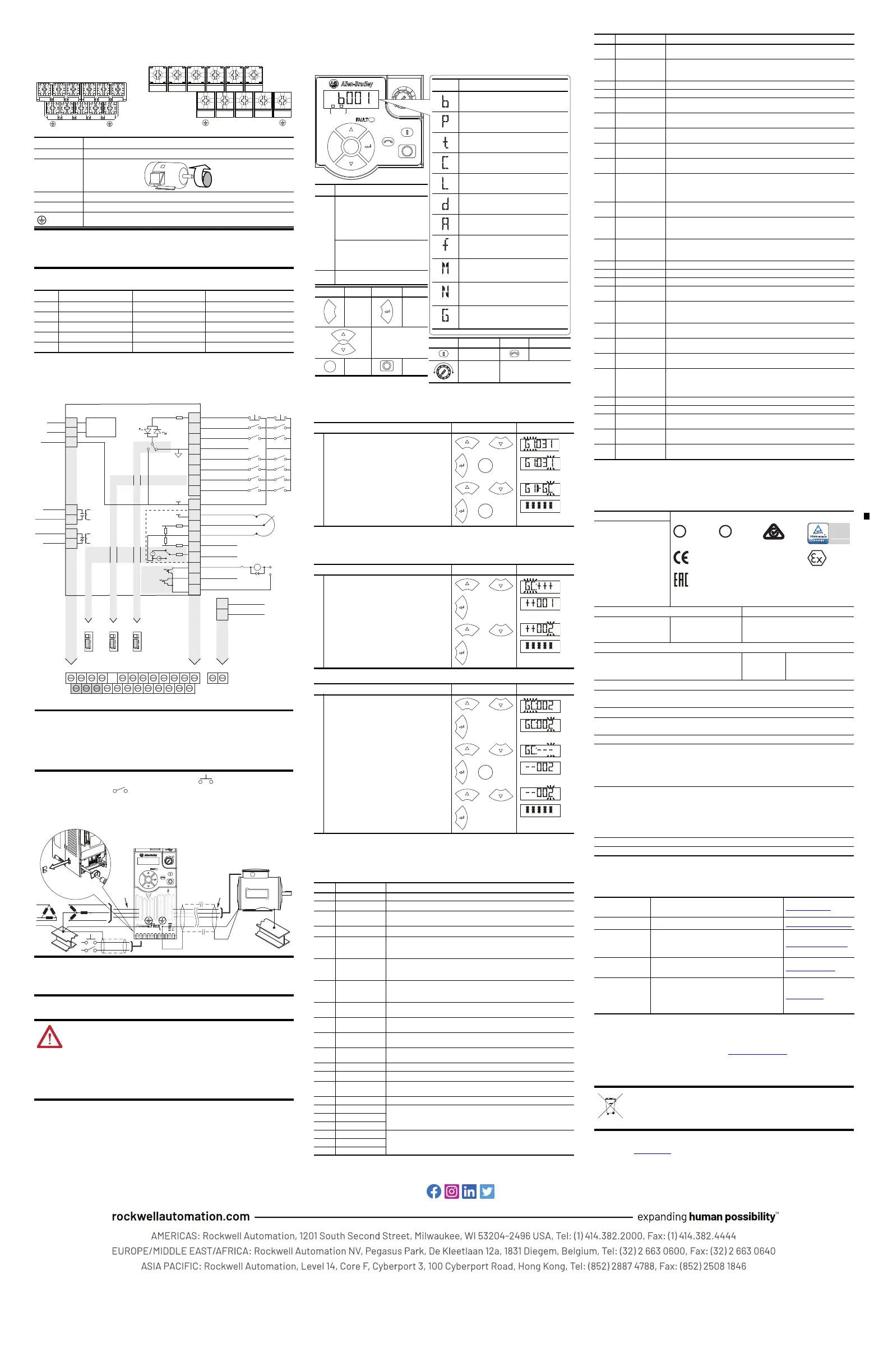

Control Terminal Block

General Grounding Requirements

Prepare For Drive Start-Up

LCD Display with QuickView Technology

QuickView® technology enables text to scroll across the LCD display of the PowerFlex 520-series

drive. This allows you to easily configure parameters, troubleshoot faults and view diagnostic

items without using a separate device.

AppView Parameter Groups

The parameters in the AppView® parameter groups can be quickly added to the CustomView™

parameter group by doing the following:

CustomView Parameter Group

You can copy one entire AppView parameter group to the CustomView parameter group as shown

above or add individual parameters as show below.

To delete parameters from the CustomView parameter group:

Fault Codes

To clear a fault – press the Stop key if P045 [Stop Mode] is set to a value between 0...3, cycle

power, set A551 [Fault Clear] to 1 or 2, or cycle digital input if t062, t063, t065...t068 [DigIn TermBlk

xx] is set to 13.

Specifications

Rockwell Automation Support

Use these resources to access support information.

Documentation Feedback

Your comments help us serve your documentation needs better. If you have any suggestions on

how to improve our content, complete the form at rok.auto/docfeedback

.

Waste Electrical and Electronic Equipment (WEEE)

Rockwell Automation maintains current product environmental compliance information on

its website at rok.auto/pec.

Terminal Description

L1/R, L2/S, L3/T Input Line Voltage Connection

T1/U, T2/V, T3/W Motor Phase

Connection

=

Switch any two motor leads to

change forward direction.

DC+, DC- DC Bus Connection

BR+, BR- Dynamic Brake Resistor Connection

Safety Ground – PE

Terminal screws may become loose during shipment. Ensure that all

terminal screws are tightened to the recommended torque before

applying power to the drive.

Frame Maximum Wire Size

(1)

(1)

Maximum/minimum sizes that the terminal block will accept – these are not recommendations.

Minimum Wire Size

(1)

Torq ue

A 5.3 mm

2

(10 AWG) 0.8 mm

2

(18 AWG) 1.76...2.16 Nm (15.6...19.1 lb-in.)

B 8.4 mm

2

(8 AWG) 2.1 mm

2

(14 AWG) 1.76...2.16 Nm (15.6...19.1 lb-in.)

C 8.4 mm

2

(8 AWG) 2.1 mm

2

(14 AWG) 1.76...2.16 Nm (15.6...19.1 lb-in.)

D 13.3 mm

2

(6 AWG) 5.3 mm

2

(10 AWG) 1.76...2.16 Nm (15.6...19.1 lb-in.)

E26.7 mm

2

(3 AWG) 8.4 mm

2

(8 AWG) 3.09...3.77 Nm (27.3...33.4 lb-in.)

The MOV to ground jumper must be removed if the drive is installed on

an ungrounded (IT mains) or resistive grounded distribution system.

Tighten screw after jumper removal.

ATTENTION: Power must be applied to the drive to perform the following start-up

procedures. Some of the voltages present are at incoming line potential. To avoid

electric shock hazard or damage to equipment, only qualified service personnel

should perform the following procedure. Thoroughly read and understand the

procedure before beginning. If an event does not occur while performing this

procedure, Do Not Proceed. Remove All Power including user supplied control

voltages. User supplied voltages may exist even when main AC power is not applied

to the drive. Correct the malfunction before continuing.

T2/VL3/TL2/SL1/R T1/U T3/W

T2/VL3/TL2/SL1/R T1/U T3/W

BR+

BR-

DC- DC+

BR+

BR-

DC-

DC+

Frame A, B, C and D Frame E

04

05

06

07

01

02

03

08

11

12

13

14

15

16

17

18

19

Digital Common

DigIn TermBlk 05

DigIn TermBlk 06

DigIn TermBlk 07/Pulse

Stop

(1)

DigIn TermBlk 02/

Start/Run FWD

(2)

DigIn TermBlk 03/

Direction/Run REV

DigIn TermBlk 08

R1

R2

S1

S2

S+

Relay 1 N.O.

Relay 1 Common

+24V DC

+10V DC

0-10V (or ±10V) Input

Analog Common

4-20mA Input

Analog Output

Opto Output 1

Opto Output 2

RJ45 Shield

Comm Common

Opto Common

+24V

+10V

Safety 1

Safety 2

Safety +24V

Typical

SNK wiring

Typical

SRC wiring

R1

S1 S2 S+ 11 12 13 14 15 16 17 18 19

R2 R5 R6 01 02 03 04 05 06 07 08 C1 C2

30V DC

50 mA

Non-inductive

Common

24V

(3)

Pot must be

1...10 k ohm

2 W min.

0-10V

0/4-20 mA

SNK

Digital In

DigIn TermBlk 07 Sel

Analog Out

Pulse In

SRCDigital

Input

0/4-20mA

0-10V

SRCSNK

R5

R6

Relay 2 Common

Relay 2 N.C.

C1

C2

Safe-Torque-O

Control I/O Wiring Block Diagram

I/O Terminal 01 is always a stop input. The stopping mode is

determined by the drive setting.

The drive is shipped with a jumper installed between I/O Terminals 01

and 11. Remove this jumper when using I/O Terminal 01 as a stop or

enable input.

(2) Two wire control shown. For three wire control use a momentary input on I/O Terminal 02 to command a

start. Use a maintained input for I/O Terminal 03 to change direction.

(3) When using an opto output with an inductive load such as a relay, install a recovery diode parallel to the relay as

shown, to prevent damage to the output.

U/T1

V/T2

W/T3

R/L1

S/L2

T/L3

SHLD

Esc

Sel

Step Key(s) Example Displays

1.

2.

3.

4.

Press the Up Arrow or Down Arrow to scroll to an

AppView group (G1...G8).

Press Enter or Sel to enter a group. The rightmost

digit of the last viewed parameter in that group will

flash.

Press the Up Arrow or Down Arrow to scroll to the

command G1->GC.

Press Enter or Sel to add all the parameters in this

AppView group to the CustomView group. The LCD

display will show a confirmation.

Step Key(s) Example Displays

1.

2.

3.

4.

Press the Up Arrow or Down Arrow to scroll to the

CustomView group (GC).

Press Enter to view the parameters that can be added

to the CustomView group.

Press the Up Arrow or Down Arrow to scroll through

the list of parameters.

Press Enter to add the parameter to the CustomView

group. The LCD display will show a confirmation.

Step Key(s) Example Displays

1.

2.

3.

4.

5.

6.

Press the Up Arrow or Down Arrow to scroll to the

CustomView group (GC).

Press Enter to view the parameters that are in the

CustomView group.

Press the Up Arrow or Down Arrow to scroll to the

command GC---.

Press Enter or Sel to view the parameters that are

stored in the CustomView group.

Press the Up Arrow or Down Arrow to scroll through

the list of parameters.

Press Enter to delete the parameter from the

CustomView group. The LCD display will show a

confirmation.

No. Fault Description

F000 No Fault –

F002

(1)

Auxiliary Input Check remote wiring. Verify communications programming for intentional fault.

F003 Power Loss Monitor the incoming AC line for low voltage or line power interruption. Check

input fuses. Reduce load.

F004

(1)

UnderVoltage Monitor the incoming AC line for low voltage or line power interruption.

F005

(1)

OverVoltage Monitor the AC line for high line voltage or transient conditions. Bus overvoltage

can also be caused by motor regeneration. Extend the decel time or install

dynamic brake resistor.

F006

(1)

Motor Stalled Increase P041, A442, A444 or A446 [Accel Time x] or reduce load so drive output

current does not exceed the current set by parameter A484 or A485 [Current

Limit x]. Check for overhauling load.

F007

(1)

Motor Overload An excessive motor load exists. Reduce load so drive output current does not

exceed the current set by parameter P033 [Motor OL Current]. Verify A530 [Boost

Select] setting.

F008

(1)

Heatsink OvrTmp Check for blocked or dirty heat sink fins. Verify that ambient temperature has

not exceeded the rated ambient temperature. Check fan.

F009

(1)

CC OvrTmp Check product ambient temperature. Check for airflow obstruction. Check for

dirt or debris. Check Fan.

F012 HW OverCurrent Check programming. Check for excess load, improper A531 [Boost Select]

setting, DC brake volts set too high or other causes of excess current.

F013

(2)

Ground Fault Check the motor and external wiring to the drive output terminals for a grounded

condition.

F015 Load Loss Verify connections between motor and load. Verify level and time requirements.

F021

(1)

Output Ph Loss Verify motor wiring and motor.

F029

(1)

Analog In Loss An analog input is configured to fault on a signal loss. A signal loss has occurred.

Check for broken/loose connections at inputs. Check parameters.

F033 Auto Rstrt Tries Correct the cause of the fault and manually clear.

F038 Phase U to Gnd Check the wiring between the drive and motor. Check motor for grounded phase.

Replace drive if fault cannot be cleared.

F039 Phase V to Gnd

F040 Phase W to Gnd

F041 Phase UV Short Check the motor and drive output terminal wiring for a shorted condition.

Replace drive if fault cannot be cleared.

F042 Phase UW Short

F043 Phase VW Short

F

W

D

ENET LINK

EtherNet/IP

➊

Menu Parameter Group & Description

Basic Display

Commonly viewed drive operating conditions.

Basic Program

Commonly used programmable functions.

Terminal Blocks

Programmable terminal functions.

Communications

Programmable communication functions.

Logic

Programmable logic functions.

Advanced Display

Advanced drive operating conditions.

Advanced Program

Remaining programmable functions.

Fault and Diagnostic

Consists of list of codes for specific fault

conditions.

Modified

Functions from the other groups with values

changed from default.

Network

Network functions that are shown only when

a comm card is used.

AppView and CustomView

Functions from the other groups organized

for specific applications.

No. Display/LED (Color)

➊

ENET (Steady) – Adapter connected to

network and drive controlled via

Ethernet.

ENET (Flashing) – Adapter connected

to network but drive not controlled via

Ethernet.

LINK (Steady) – Adapter connected to

network but not transmitting data.

LINK (Flashing) – Adapter connected to

network and transmitting data.

➋

Fault Status (Red)

Key Name Key Name

Escape Enter

Up Arrow

Down Arrow

Select Stop

➋

Key Name Key Name

Start Reverse

Potentiometer

F

W

D

F

W

D

F

W

D

F

W

D

F

W

D

F

W

D

PROGR

A

M

F

W

D

F048

(1)

Params Defaulted The drive was commanded to write default values to EEPROM. Clear the fault or

cycle power to the drive. Program the drive parameters as needed.

F059

(1)

Safety Open Both of the safety inputs (Safety 1, Safety 2) are not enabled. Check safety input

signals. If not using safety, verify and tighten jumper for I/O terminals S1, S2 and

S+.

F063

(1)

SW OverCurrent Verify connections between motor and load. Verify level and time requirements.

F064 Drive Overload Reduce load or extend Accel Time.

F070 Power Unit Check maximum ambient temperature has not been exceeded. Cycle power.

Replace drive if fault cannot be cleared.

F071 DSI Net Loss Cycle power. Check communications cabling. Check Modbus or DSI setting.

Check Modbus or DSI status.

F072 Opt Net Loss Cycle power. Check communications cabling. Check network adapter setting.

Check external network status.

F073 EN Net Loss Cycle power. Check communications cabling. Check EtherNet/IP™ setting. Check

external network status.

F080 Autotune Failure The autotune function was either cancelled by the user of failed. Restart

procedure.

F081 DSI Comm Loss Cycle power. Check communications cabling. Check Modbus or DSI setting.

Check Modbus or DSI status. Modify using C125 [Comm Loss Action]. Connecting

I/O terminals C1 and C2 to ground may improve noise immunity.

Replace wiring, Modbus master device or control module.

F082 Opt Comm Loss Cycle power. Reinstall option card in drive. Modify using C125 [Comm Loss

Action]. Replace wiring, port expander, option card or control module.

F083 EN Comm Loss Cycle power. Check EtherNet/IP setting. Check drive’s Ethernet settings and

diagnostic parameters. Modify using C125 [Comm Loss Action]. Replace wiring,

Ethernet switch or control module.

F091 Encoder Loss Check Wiring. If P047, P049 or P051 [Speed Referencex] = 16 “Positioning” and

A535 [Motor Fdbk Type] = 5 “Quad Check”, swap the Encoder channel inputs or

swap any two motor leads. Replace encoder.

F094 Function Loss Close input to the terminal and cycle power.

F100 Parameter Chksum Set P053 [Reset to Defalts] to 2 “Factory Rset”.

F101 External Storage Set P053 [Reset to Defalts] to 2 “Factory Rset”.

F105 C Connect Err Clear fault and verify all parameter settings. Do not remove or install the control

module while power is applied.

F106 Incompat C-P The control module could not recognize the power module. Cycle power. Flash

with newer firmware version.

Replace drive if fault cannot be cleared.

F107 Replaced C-P The control module was mounted to a power module with a different power

rating. Set P053 [Reset to Defalts] to any of the reset options.

F109 Mismatch C-P The control module was mounted to a different drive type power module. Set

P053 [Reset to Defalts] to any of the reset options.

F110 Keypad Membrane Keypad membrane failure/disconnected. Cycle power.

Replace control module if fault cannot be cleared.

F111 Safety Hardware Safety input enable hardware malfunction. One of the safety inputs is not

enabled. Check safety input signals. If not using safety, verify and tighten jumper

for I/O terminals S1, S2 and S+.

Replace control module if fault cannot be cleared.

F114 uC Failure Cycle power. Replace control module if fault cannot be cleared.

F122 I/O Board Fail Cycle power. Replace drive or control module if fault cannot be cleared.

F125 Flash Update Req Perform a firmware flash update operation to attempt to load a valid set of

firmware.

F126 NonRecoverablErr Clear fault or cycle power to the drive. Replace drive or control module if fault

cannot be cleared.

F127 DSIFlashUpdatReq Perform a firmware flash update operation using DSI communications to

attempt to load a valid set of firmware.

(1)

This fault may be cleared by the auto-restart routine and will be attempted a number of times based on the value set

in parameter A541 [Auto Rstrt Tries].

(2)

This fault may be cleared by the auto-restart routine and will be attempted only once. It ignores the value set in

parameter A541 [Auto Rstrt Tries].

Input/Output Ratings Approvals

Output Frequency:

0...500 Hz

(Programmable)

Efficiency:

97.5% (Typical)

Digital Control Inputs (Input Current = 6 mA) Analog Control Inputs

SRC (Source) Mode:

18...24V = ON

0...6V = OFF

SNK (Sink) Mode:

0...6V = ON

18...24V = OFF

4-20 mA Analog: 250 input impedance

0-10V DC Analog: 100 k input impedance

External Pot: 1...10 k, 2 W min.

Control Output

Programmable Output, Form A and Form B

Resistive Rating: 3.0 A @ 30V DC, 125V AC and 240V AC

Inductive Rating: 0.5 A @ 30V DC, 125V AC and 240V AC

Opto Outputs

30V DC, 50 mA

Non-inductive

Analog Outputs (10-bit)

0-10V: 1 k min.

4-20 mA: 525 max.

Fuses and Circuit Breakers

Recommended Fuse Type: UL Class J, T or Type BS88; 600V (550V) or equivalent.

Recommended Circuit Breakers: HMCP or equivalent.

Protective Features

Motor Protection:

I

2

t overload protection – 150% for 60 s, 200% for 3 s (Provides Class 10 protection)

Overcurrent: 200% hardware limit, 300% instantaneous fault

Over Voltage:

100...120V AC Input – Trip occurs @ 405V DC bus voltage (equivalent to 150V AC incoming line)

200...240V AC Input – Trip occurs @ 405V DC bus voltage (equivalent to 290V AC incoming line)

380...480V AC Input – Trip occurs @ 810V DC bus voltage (equivalent to 575V AC incoming line)

525...600V AC Input – Trip occurs @ 1005V DC bus voltage (equivalent to 711V AC incoming line)

Under Voltage:

100...120V AC Input – Trip occurs @ 190V DC bus voltage (equivalent to 75V AC incoming line)

200...240V AC Input – Trip occurs @ 190V DC bus voltage (equivalent to 150V AC incoming line)

380...480V AC Input – Trip occurs @ 390V DC bus voltage (equivalent to 275V AC incoming line)

525...600V AC Input – If P038 = 3 “600V” trip occurs @ 487V DC bus voltage (344V AC incoming line);

– If P038 = 2 “480V” trip occurs @ 390V DC bus voltage (275V AC incoming line)

Control Ride Through: Minimum ride through is 0.5 s - typical value 2 s

Faultless Power Ride Through: 100 ms

Technical Support

Center

Find help with how-to videos, FAQs, chat, user

forums, and product notification updates.

rok.auto/support

Knowledgebase Access Knowledgebase articles. rok.auto/knowledgebase

Local Technical

Support Phone

Numbers

Locate the telephone number for your country. rok.auto/phonesupport

Literature Library

Find installation instructions, manuals,

brochures, and technical data publications.

rok.auto/literature

Product

Compatibility and

Download Center

(PCDC)

Download firmware, associated files (such as

AOP, EDS, and DTM), and access product release

notes.

rok.auto/pcdc

At the end of life, this equipment should be collected separately from

any unsorted municipal waste.

No. Fault Description

U

L

®

L

I

S

T

E

D

9

6

6

X

I

N

D

C

O

N

T

E

Q

UL508C

U

L

®

L

I

S

T

E

D

9

6

6

X

I

N

D

C

O

N

T

E

Q

C

CSA 22.2

LV Directive 2014/35/EU: EN 61800-5-1

EMC Directive 2014/30/EU: EN 61800-3

Machine Directive 2006/42/EC: EN 60261

ATEX Directive 2014/34/EU: EN 50495

RoHS Directive 2011/65/EU

N223

AC 156

KCC: Article 58-2 of Radio Waves Act, Clause 3

Lloyds Register: Approval Certificate 12/10068(E1)

SEMI F47

Low Voltage TP TC 004/2011

EMC TP TC 020/2011

II (2) G D

Functional

Safety

Type

Approved

www.tuv.com

ID 0600000000

Loading...

Loading...