EN

81

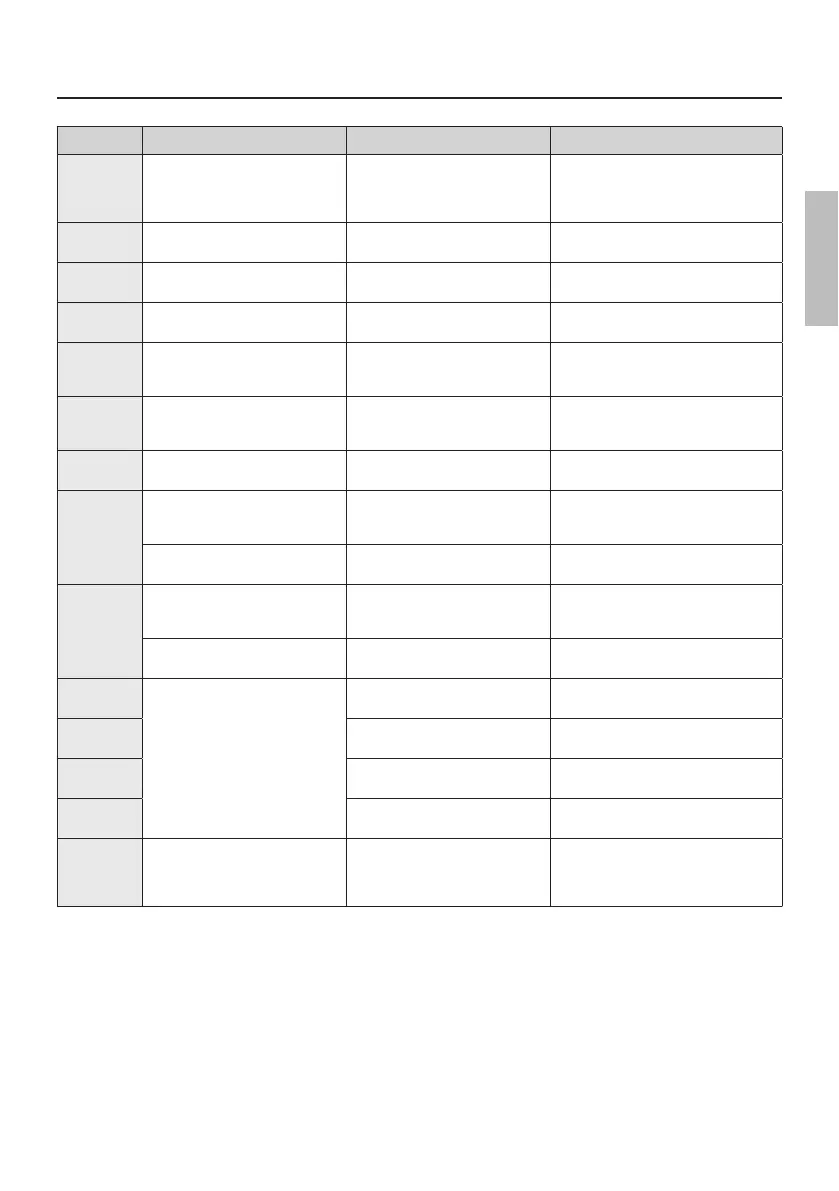

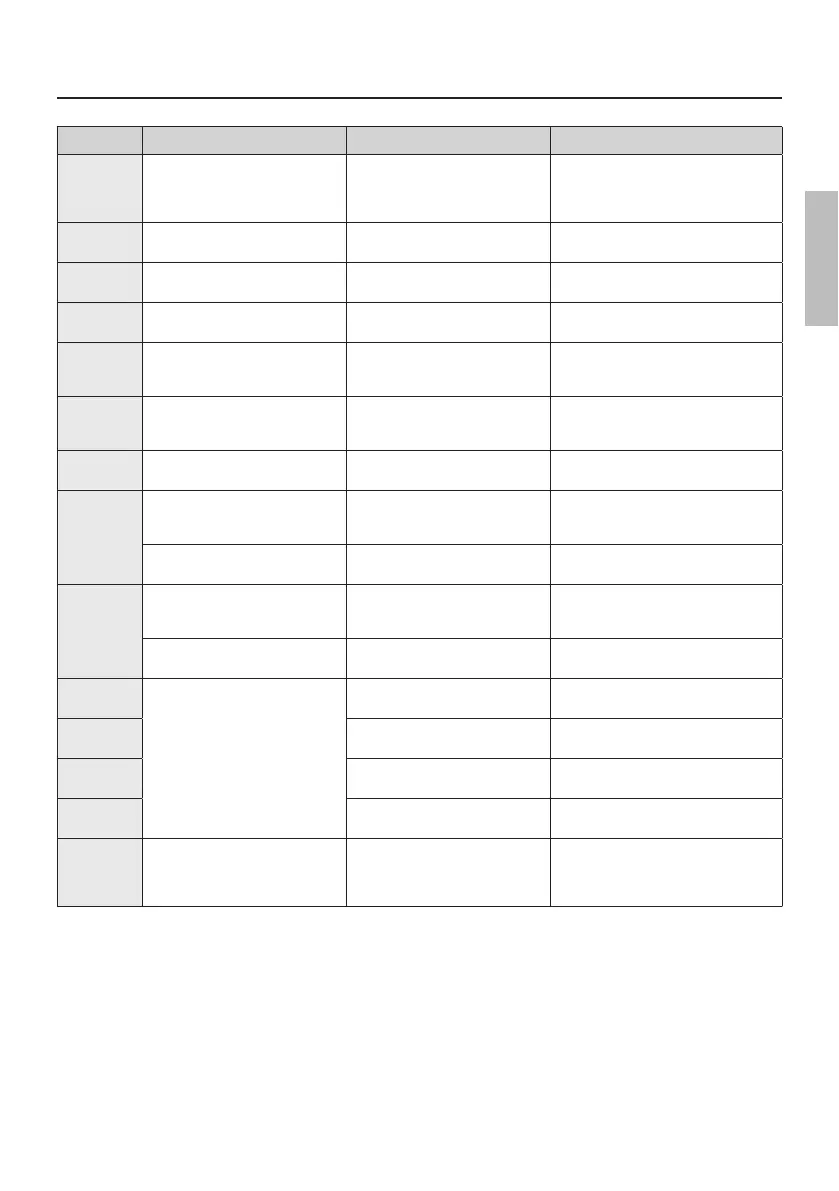

16 Safety input and command status (TEST mode)

With no currently active commands, press the TEST button and check the following:

DISPLAY POSSIBLE CAUSE ACTION BY SOFTWARE PHYSICAL CORRECTIVE ACTION

6E

(00 Sb)

The release handle is open.

-

Close the release handle and turn the key

to the close position.

Check that the release contact is con-

nected correctly.

The safety STOP contact is open.

-

Install a STOP button (NC) or jumper the

ST contact with the COM contact.

Sensing edge COS1 not connected

or incorrectly connected.

Set the parameter if not used

or to disable

Jumper contact COS1 with contact COM,

if not used or to disable

Sensing edge COS2 not connected

or incorrectly connected.

Set the parameter if not used

or to disable

Jumper contact COS2 with contact COM,

if not used or to disable

Photocell FT1 not connected or in-

correctly connected.

Set the parameter e if

not used or to disable

Jumper contact FT1 with contact COM, if

not used or to disable. Check connection

referring to relative connection diagram.

Photocell FT2 not connected or in-

correctly connected.

Set the parameter e if

not used or to disable

Jumper contact FT2 with contact COM, if

not used or to disable. Check connection

referring to relative connection diagram.

)(

Both limit switches in open contact

state or not connected.

-

Check connection of limit switches.

)$

Gate is at gate closed limit switch. If the limit switch state indicated is

incorrect, check the setting of para-

meter .

-

Gate open limit switch absent or not

connected.

- Check connection of limit switches.

)&

Gate is at gate closed limit switch. If the limit switch state indicated is

incorrect, check the setting of para-

meter .

-

Gate closed limit switch absent or

not connected.

-

Check connection of limit switches.

SS

If occurs with no voluntary com-

mand, the contact (N.O.) may be

faulty or one of the buttons may be

incorrectly connected.

-

Check PP - COM contacts and connec-

tions to buttons.

&+

-

Check CH - COM contacts and connec-

tions to buttons.

DS

-

Check AP - COM contacts and connec-

tions to buttons.

SH

-

Check PED - COM contacts and connec-

tions to buttons.

2U

If occurs with no voluntary com-

mand, the contact (N.O.) may be

faulty or the timer may be incor-

rectly connected.

-

Check ORO - COM contacts. Contact

must not be jumpered if not used.

N.B: press TEST to exit TEST mode.

We recommend troubleshooting safety device and input status errors with “corrective action by software” only.

Loading...

Loading...