2

Good Practice

NOTE: These are general guidelines and do not cover all possible situations.

It is the responsibility of the system integrator to apply this product properly.

Plumbing

1. The inlet pipe should be as short and straight as possible to minimize

suction pressure losses. Excessive restrictions at the inlet can cause

cavitation resulting in poor performance, noise, vibration, or pump

damage.

2. Slope the inlet plumbing appropriately to avoid air pockets.

3. Plumbing weight, misalignment with the ports or thermal expansion can

exert excessive force on the pump. Plumbing must be properly

supported and aligned with expansion joints, if required, to minimize

these forces.

4. To prevent over pressure situations, install a relief valve as close to the

pump outlet as possible. Install the relief valve before any shut-off

valves.

Separate Pump and Drive Assemblies

Driveline Guards

1. Assure adequate guards have been installed to prevent personnel

contacting moving components.

2. Follow all OSHA, Federal, state and local codes.

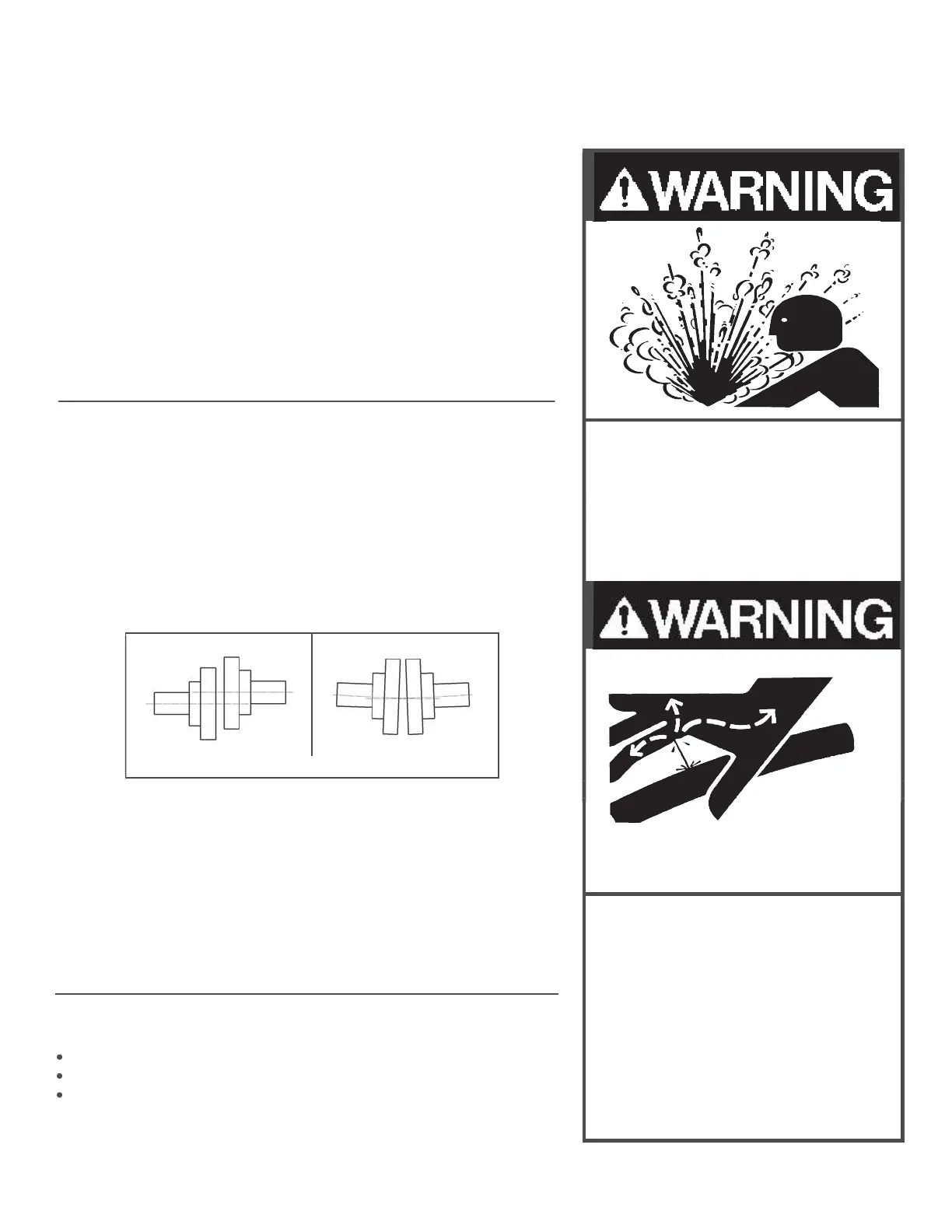

Check Alignment of Pump to Driveline

Excessive misalignment can overload the pump input shaft and cause

premature failure. The figures below show parallel and angular

misalignments.

Parallel Angular

Mounting Base

1. Mount the unit on a rigid, heavy base to provide support and absorb

shock. Bases should be designed for high rigidity, not just strength.

2. The pump feet were not designed for mounting to concrete and do not

have enough contact area to prevent concrete from failing. When

mounting to cement or concrete, use a steel base plate to distribute the

mounting stress over an area large enough to prevent the cement from

failing. The base plate should be at least as thick as the pump feet.

Grout it in place.

Roper Pumps’ Close Coupled Drives

Hydraulic or Gearmotor units where the drive mounts directly to the pump

Driveline is not exposed and does not require guards.

Alignment between pump and drive line is maintained by the assembly.

Because the assembly absorbs reaction forces of the driveline, the

mounting base does not need to be as robust. The level of rigidity and

strength is determined by the piping stresses from the system.

Over-pressure may burst

pump or system components.

Always include a relief valve

in installation. Do not over

pressurize pump or block

dischar

e line while runnin

.

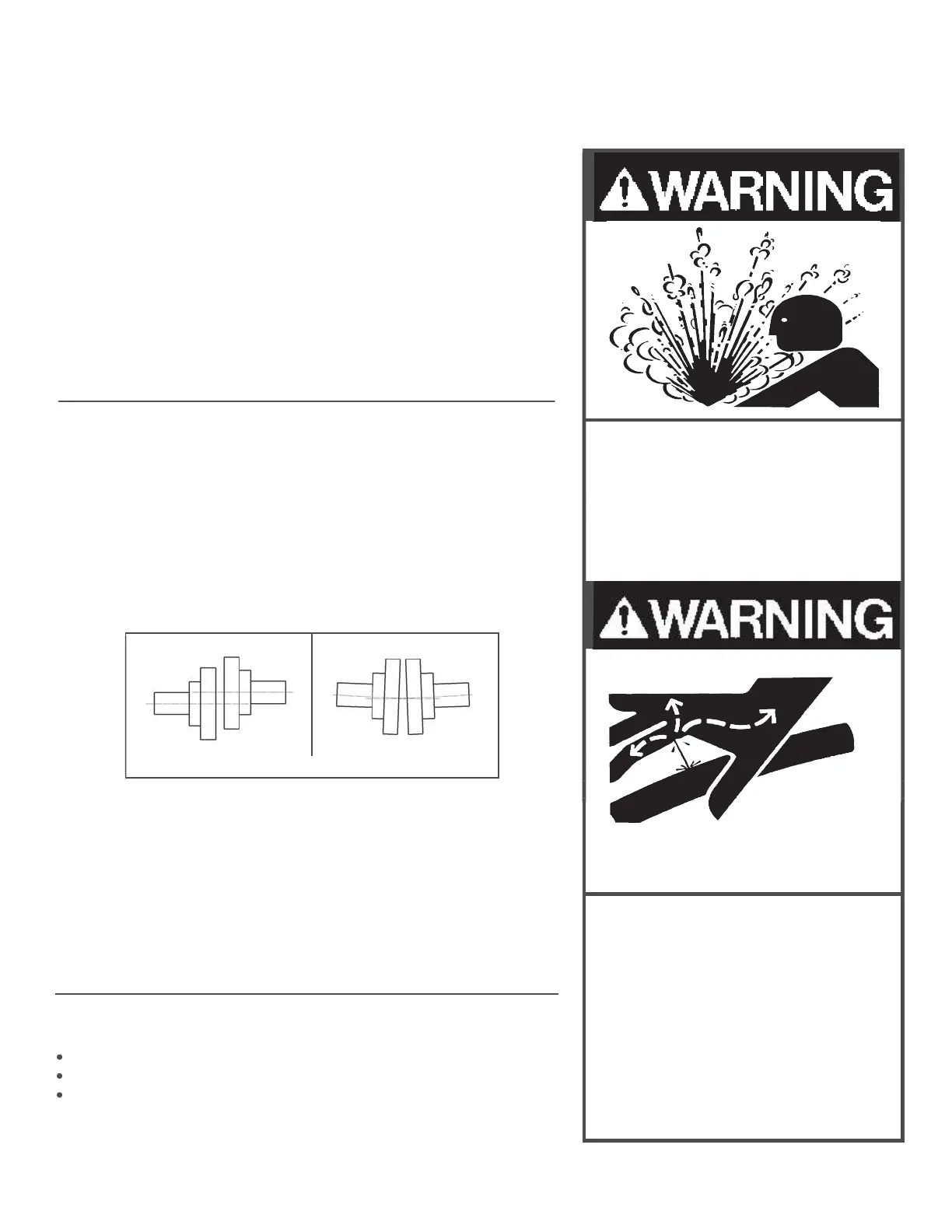

Injection Hazard: Do not try to

stop a leak with your hand!

Avoid any close contact with

hydraulic fluid jets. Escaping

fluid can penetrate skin, causing

serious injury. In case of

accident, see a doctor

immediatel

for removal of fluid.

Loading...

Loading...