6. Installation

Important:

Always wear safety glasses while installing lift.

Required Tools and Supplies List

1. 3 phase 380V, 50 Hz, 10 amp service

2. Single phase 208-230V, 50 Hz or 60 Hz, 30 amp

service

3. 15 liters of ATF Dexron III or hydraulic fluid that

meets ISO 32 specifications

4. Chalk line

5. Tape measure, 5M min.

6. Level, 2M min.

7. Open end wrenches

8. Needle nose pliers

9. Cross head screw driver

10. Oil funnel

11. Hammer drill

7. Surface Mount & Flush Mount Control Cabinet Layout

Layout the service bay according to the architect’s

plans or owners instructions. Failure to install in

this orientation can result in personal and property

damage. Be certain that the proper conditions exists,

see previous page.

Note: The correct orientation of the platforms is critical

for proper layout of the lift.

Place the control cabinet in the approximate location

(do not anchor), Fig. 3. Relocating the control cabinet

further away than the standard distance will require

the installer to provide suitable hydraulic hoses.

Additional hose covers will also be needed if installing

the control cabinet at a further distance than the

standard distances in surface mount configurations.

Hydraulic hoses should be 6mm min. ID with a min.

working pressure of 5800 psi with #6 JIC Swivel Female

fittings. Extension Hose Kits available.

8. Flush Mount Pit Requirements

Prior to pouring concrete, installer will need either the

Full Flush Mount Kit (part # XX100003) or Recess Box

Flush Mount Kit (part # XX100014). Please contact the

phone number listed on the front cover of the manual

for additional assistance. The Full Flush Mount Kit

contains frame components with concrete ties that

will need to be placed during concrete pour. See parts

breakdown manual for included components. Pit forms

are not provided and will be the responsibility of the

installer.

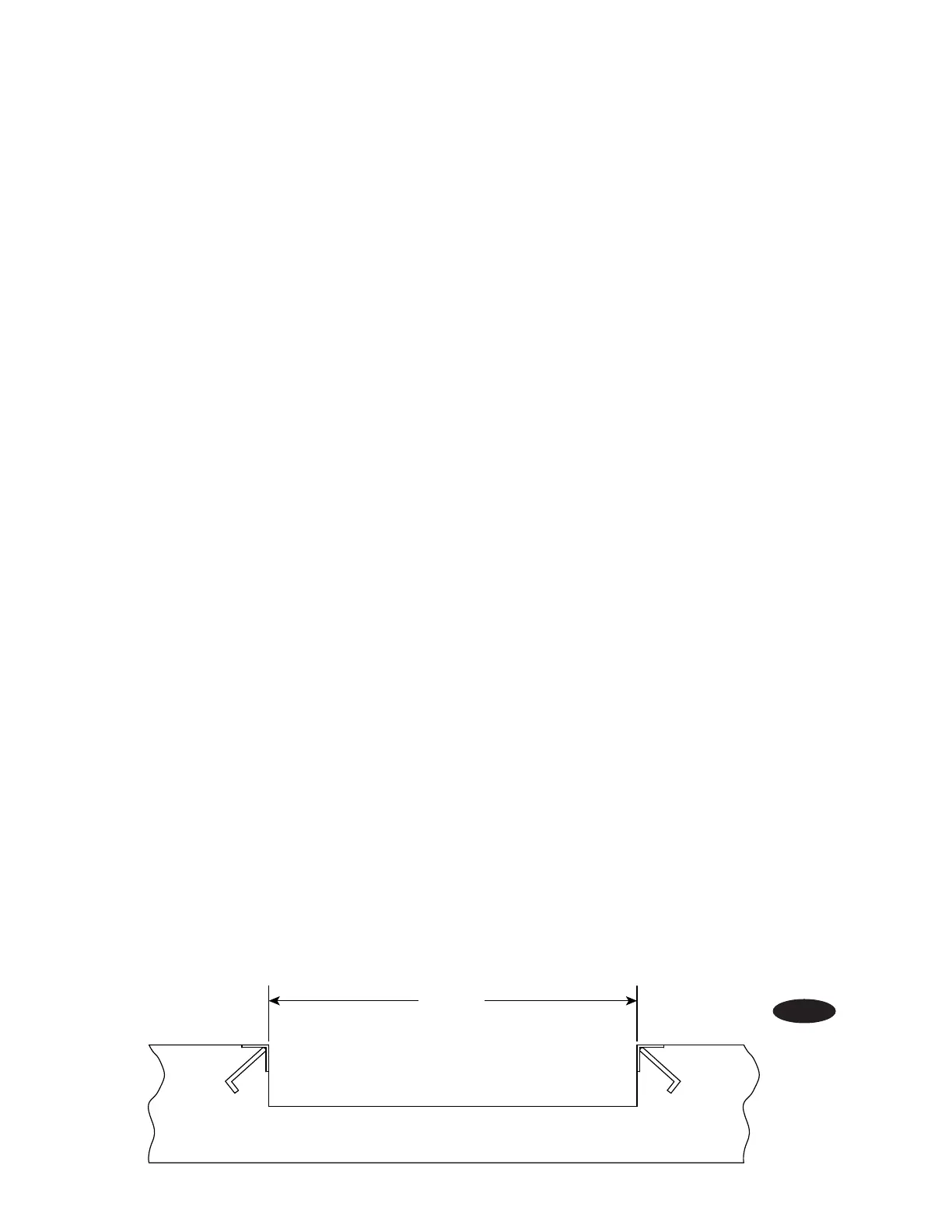

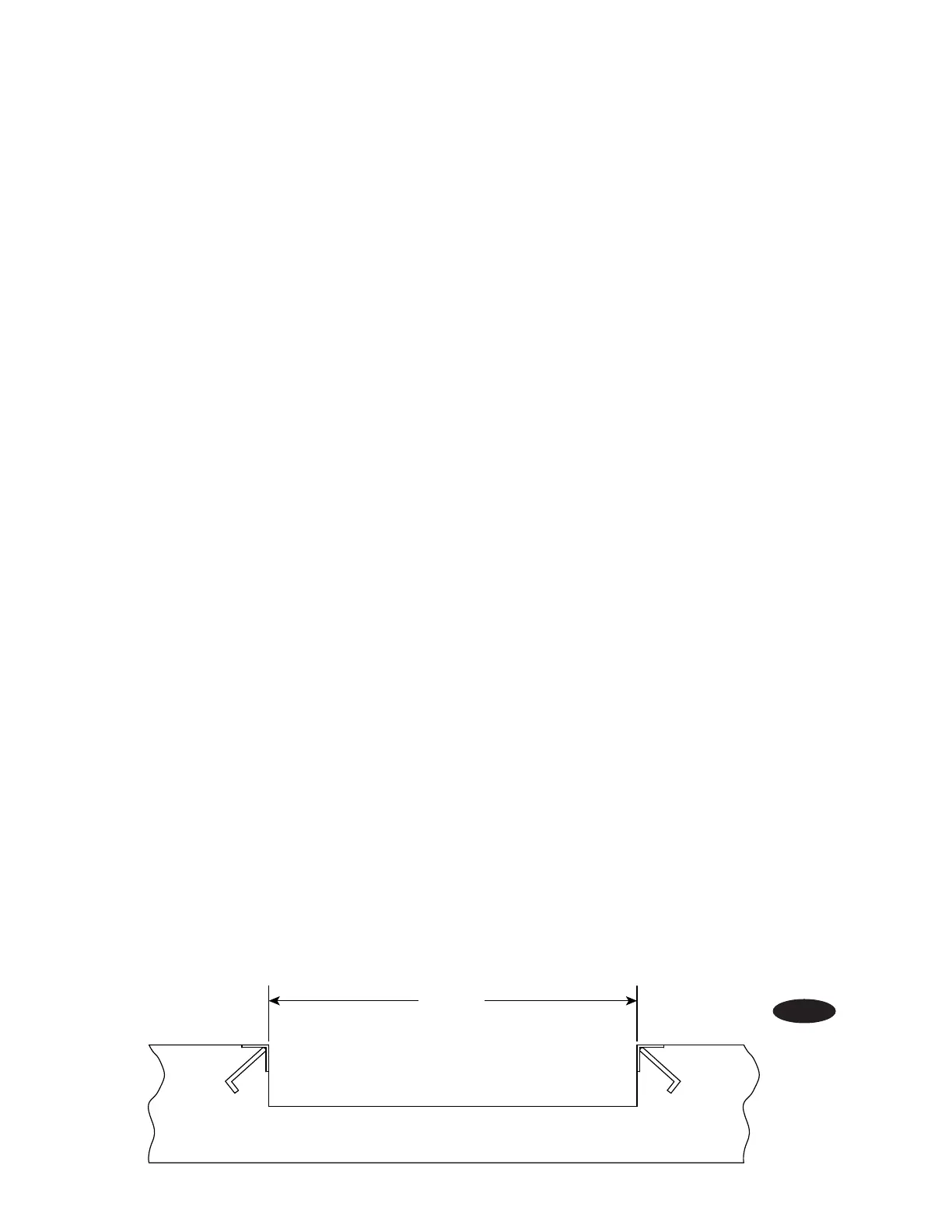

Bend frame anchors outward, perpendicular to angle

frame, and downward approximately 45° to floor level,

Fig. 2.

Place the recess box in the pit and install M8 bolts

to secure to frame and anchors to pit floor. If recess

weldment is not used, fasten recess box using anchors

only, Fig. 2a. Install hose cover to recess box using M8

bolts and anchors to pit floor, Fig. 2b.

For flush mount pit specifications, Fig. 2c and Fig. 2d.

688mm

Fig. 2

6

Loading...

Loading...