arm roller is adjusted by tilting the pulley mounting block fore and aft and then securing the two 4-40

screws that hold the block to the arm. When adjusting the angle of the roller left or right, the

adjustment is made by carefully bending the vertical member of the threading arm so that the tape

travels in the middle of the roller or touches either flange

lightly.

Under no circumstances should the tape press against the flanges of the roller hard enough to

buckle or deform the tape. You will find that tilting the mounting block for and aft will adjust the

position of the tape on the roller when a tape is going in the forward direction; and in the reverse

direction, angling the arm left or right will affect the tape travel.

THREADING ARM SWITCHES

In addition to the rollers, the "in" and "out" microswitches should be adjusted to switch

approximately 3/16" prior to the arm reaching either its "out" position or its "home" position. The

threading arm is connected to the threading motor via a clutch(set to slip at 11 oz.), and the threading

motor will continue to run for a brief period after the arm "in" and arm "out" microswitches actually

switch.

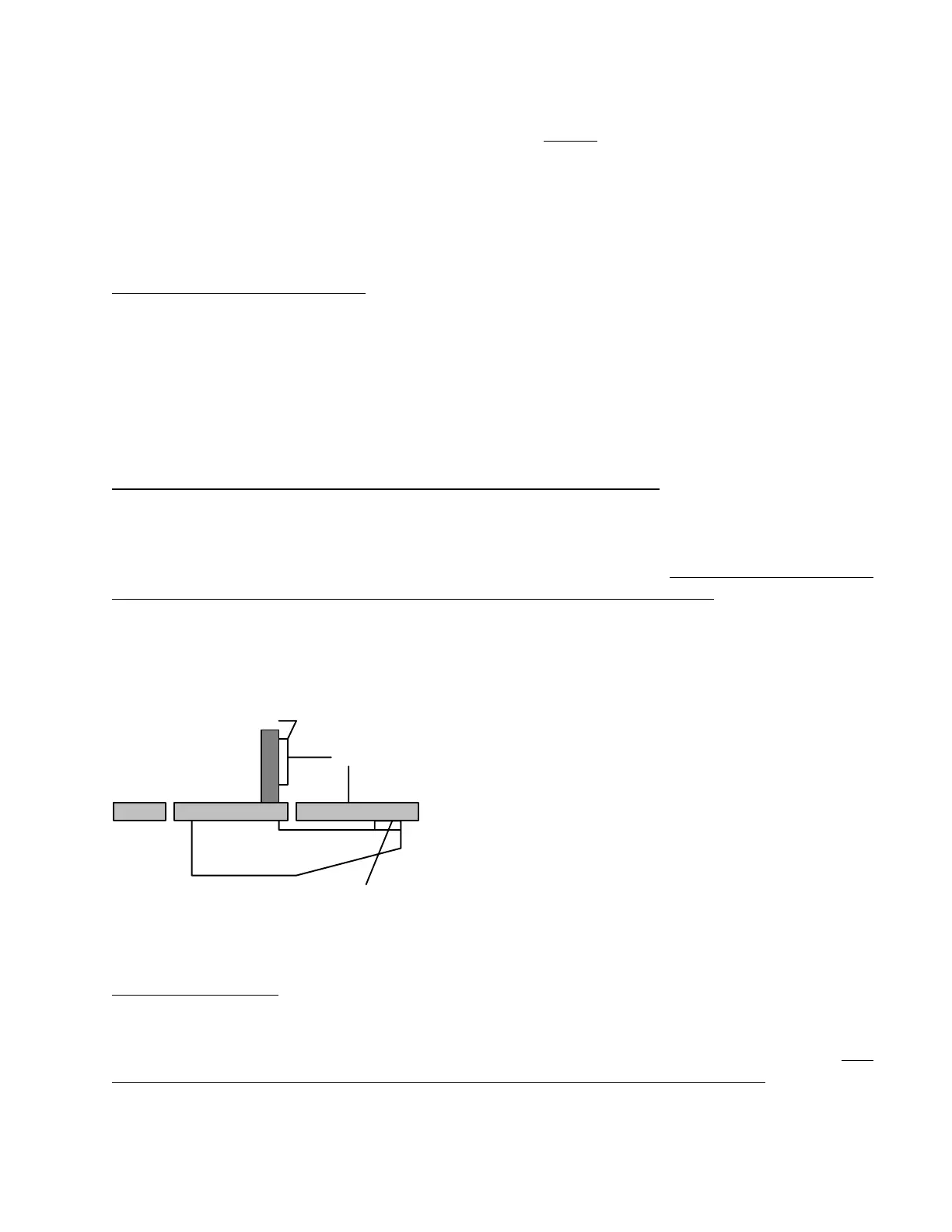

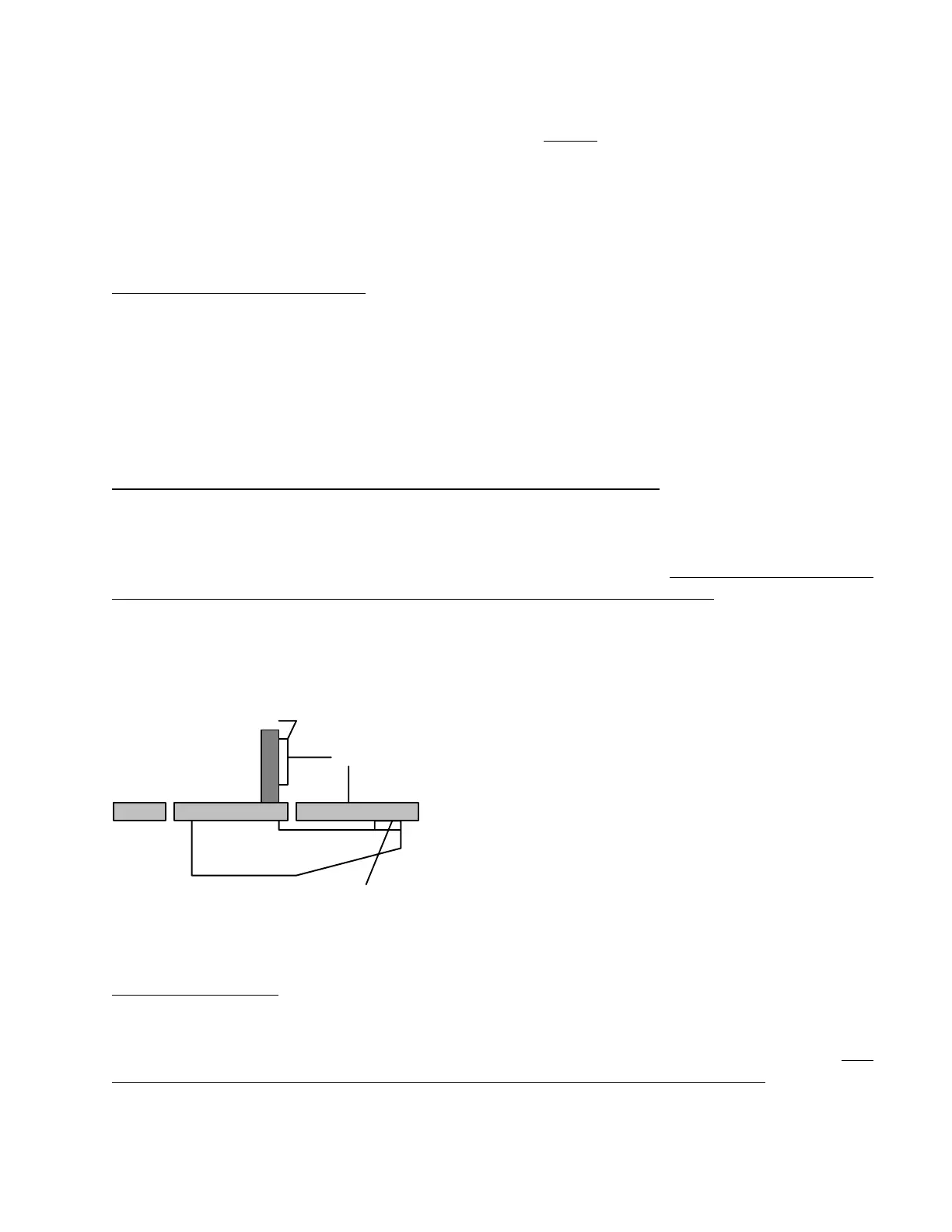

TAPE BACKUP SUPPORT BLOCK EFFECTS DEFECT DETECTION

The black support block with the sapphire support rods also needs to be square to the transport panel.

Remove the detector to check the rods for squareness(90° to the panel.) The machine automatically

brings the detector backup block into position when tape is not threaded.

It is very important that the

rods that support the tape at the detector be perpendicular to the transport panel.

The following sketch shows the moveable cleaner and the tape back-up support block with the

sapphire rods.

Cleaner

90

Main panel

rods

Shims

.

This adjustment is made by adding or removing shim washers from the pivot bracket of the

moveable cleaner assembly underneath the transport panel.

CASSETTE HEIGHT

The height of the cassette is determined by the 6 support posts on the transport panel. These

hexagonal posts are fixed and not adjustable. For proper operation of the 4100 machine,

it is

imperative that the cassette be in contact with these support posts, not the carrier floor.. NOTE: The

large cassette has a total of six support posts. Obviously, because of variations in the large cassette

housing it is not totally flat and, therefore, if four of the six posts touch the cassette, that is sufficient

to support the cassette.

22

Loading...

Loading...