SPINDLE HEIGHT

The spindles of the machine that drive the reels inside the cassette should be at .990 inches above

the transport panel. This measurement is made from the top of the

spindle flange down to the top of

the transport panel. The spindle should be at this height, plus/minus .004 inches.

CASSETTE PLUNGER SENSORS

There are five plunger-type microswitch sensors underneath the cassette. These sensors sense

large/small reel hubs, metal/oxide tape and the erase tabs for small and large cassettes. For proper

operation, these microswitches should switch approximately 1/32" prior to the cassette coming down

on its support hex post. Also, check for the free action of the plunger. The plunger should not be

sticky and should return to its full upright position easily. DO NOT LUBRICATE THE

PLUNGERS, that causes them to stick due to the tight fit in the tube. Clean, dry plungers are

desired.

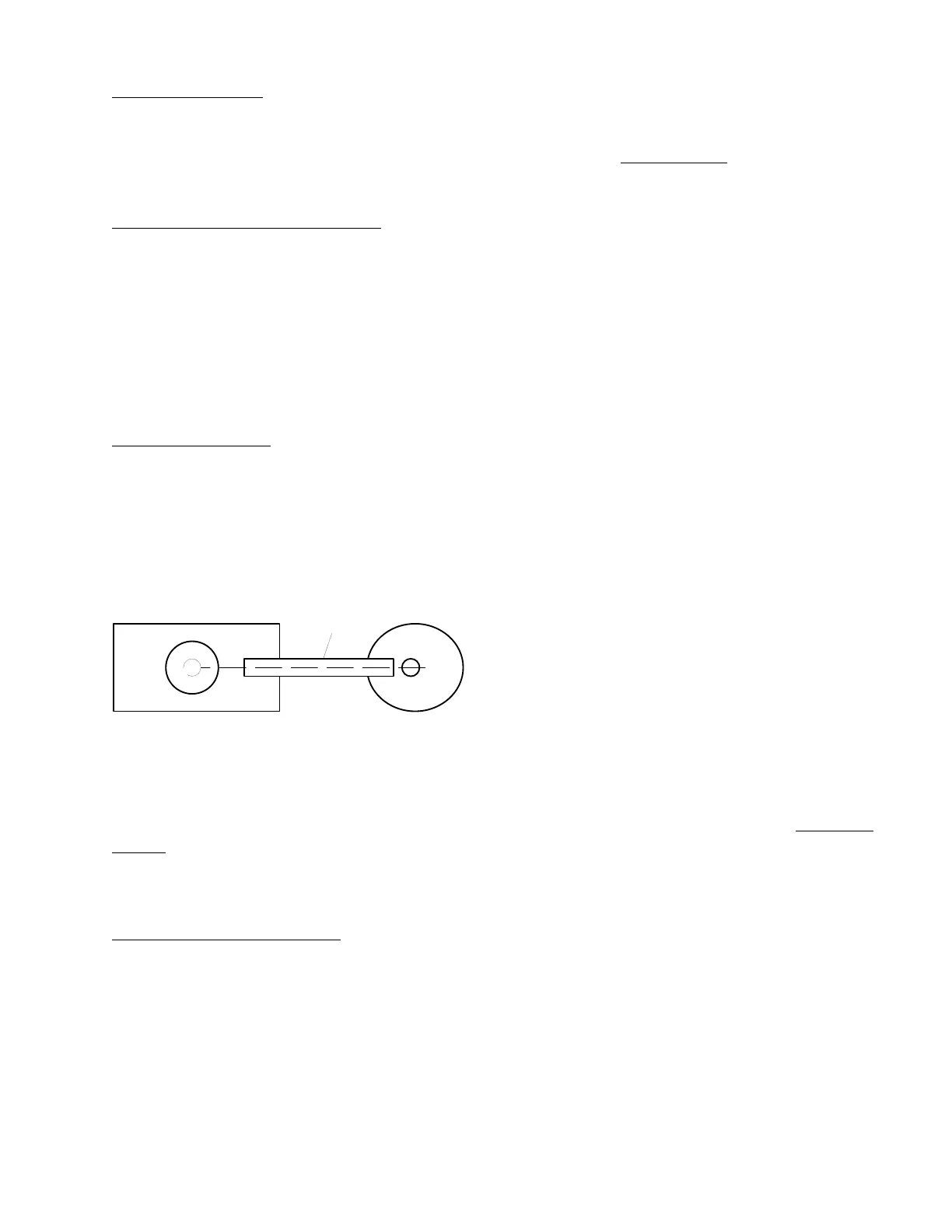

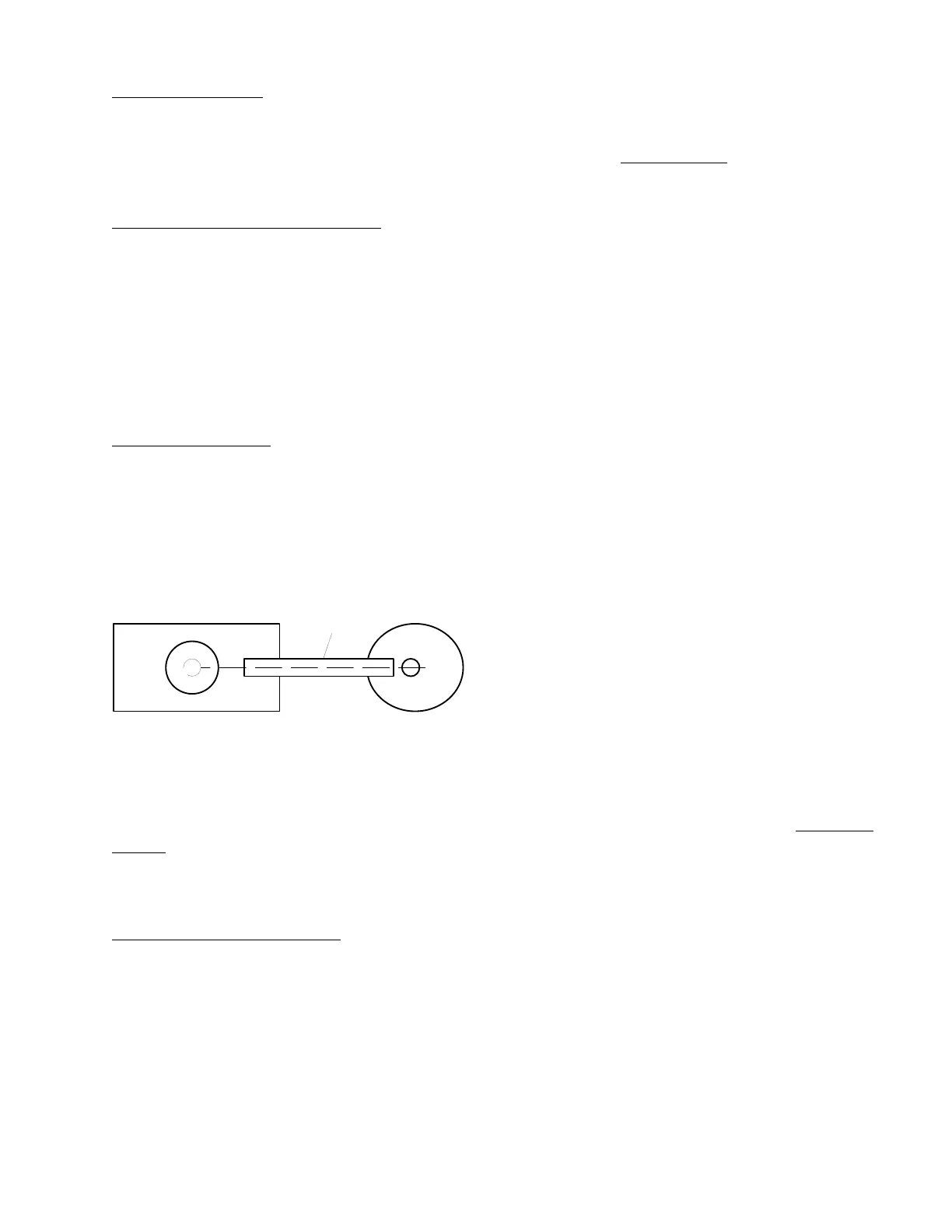

SPINDLE MOVERS

The spindles are moved to accommodate the large cassette via a gear motor and cam arrangement

with a straight arm linkage. The cam has a detente and two microswitches to stop the cam at the

appropriate position for the two sizes of cassettes. The arms of the microswitch may have to be bent

slightly (when installing a replacement switch) so that the switch operates reliably in the detente of

the cam.

Slide

Cam

Linkage

.

.

The linkage should be in a straight line from the pivot point of the cam to the spindle slide in the

"in" and "out" positions (180

°

apart). Check that both spindle cams are in the same relative position.

If they are not, the timing belt may have to be adjusted. This is accomplished by removing the

bearing roller that rides on the timing belt, cause slack in the belt and manually rotate the

right-hand

spindle until the proper orientation is achieved. Then reattach the timing belt bearing roller.

WARNING: Keep your hands and clothing out of the slides when they are operating.

CARRIER LIFT ASSEMBLY

The carrier is moved up and down by a gear motor with gears and linkage arms underneath panel.

The rotating arm is connected to the carrier via round linkages that are covered by a spring. When the

carrier is in the "down" position, the spring extends to add further down pressure, holding the cassette

in place. The rotating linkage should be approximately vertical when the carrier is in the up position

and straight down when the carrier is in the down position. The carrier lift motor is turned "on" and

"off" via two optical sensors on the back edge of the carrier floor. A tall "U" shaped bracket

interrupts the two optical sensor beams and causes the carrier to stop in the up and down position,

respectively. Once the "flags" of this "U" shaped bracket are trimmed to the proper the height at the

22

Loading...

Loading...