SAVE THIS MANUAL FOR FUTURE REFERENCE

The saw has been engineered and manufactured to our high standard for dependability, ease of operation, and operator

safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

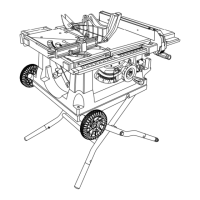

10 in. TABLE SAW

SCIE À TABLE de 254 mm (10 po)

SIERRA DE MESA de 254 mm (10 pulg.)

RTS12T

Cette scie a été conçue et fabriquée conformément aux strictes

normes de fiabilité, simplicité d’emploi et sécurité d’utilisation.

Correctement entretenu, cet outil vous donnera des années de

fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Su sierra ha sido diseñado y fabricado de conformidad con

nuestras estrictas normas para brindar fiabilidad, facilidad de uso

y seguridad para el operador. Con el debido cuidado, le brindará

muchos años de sólido funcionamiento y sin problemas.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS