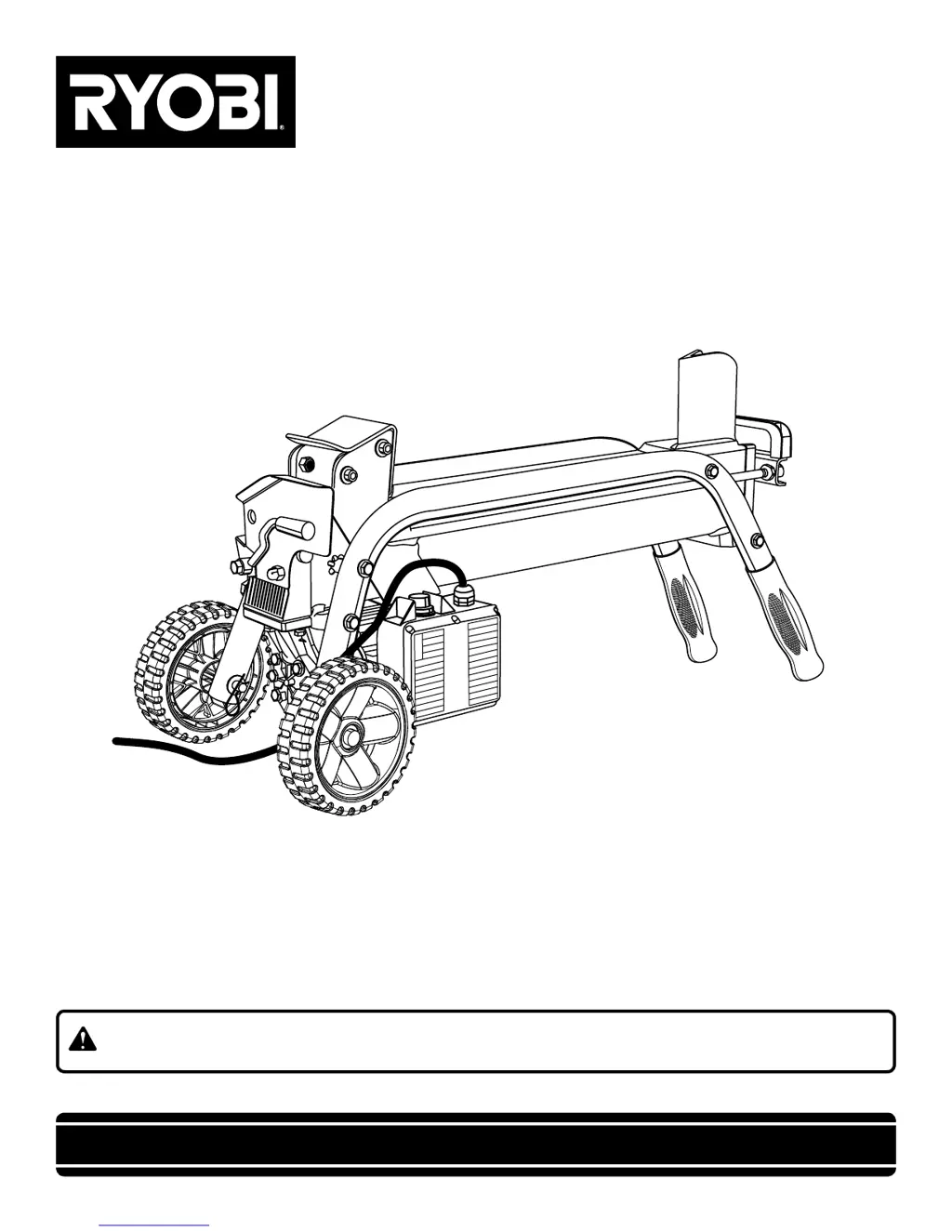

What to do if my Ryobi RY49701 Log Splitter won’t split logs?

- CCarolyn PowersJul 29, 2025

If your Ryobi Log Splitter won’t split logs, several issues could be the cause. First, ensure the log is correctly positioned according to the Operation section. If the log is too large or hard for the machine, reduce its size. Other potential causes are oil leaks (locate them and contact the dealer), a blunt wedge cutting edge (refer to 'Sharpening Wedge' in the Maintenance section), or an unauthorized adjustment to the Maximum Pressure Limiting Screw (contact the dealer).