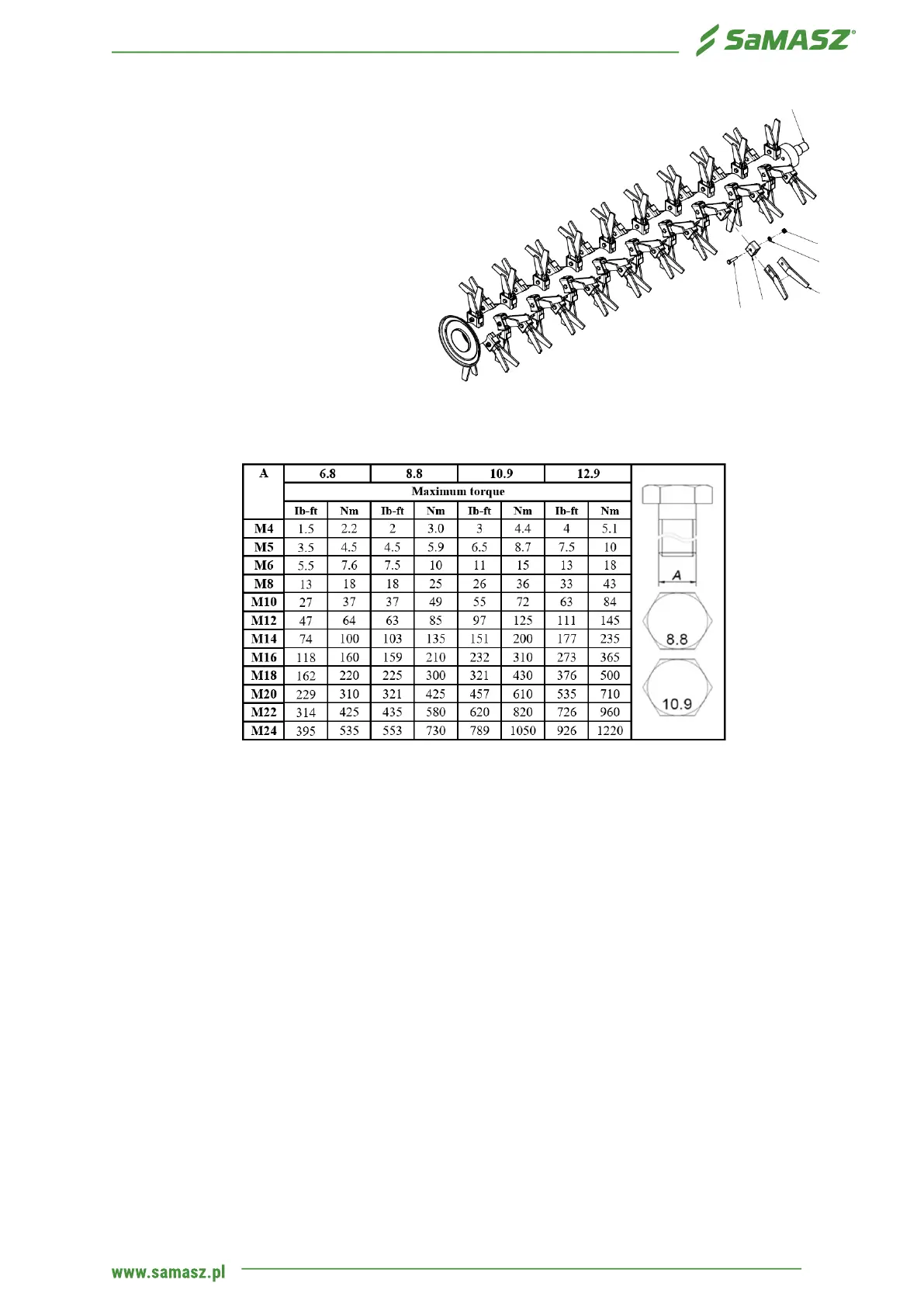

1. Scarfier shaft

2. Self-locking nut M12 oc. kl. 8

3. Washer

4. Plastic flail

5. Bolt M12x55 oc. kl. 8.8

6. Plastic flail insert

Fig. 32b. Replacement of flails in light-weight conditioner roller

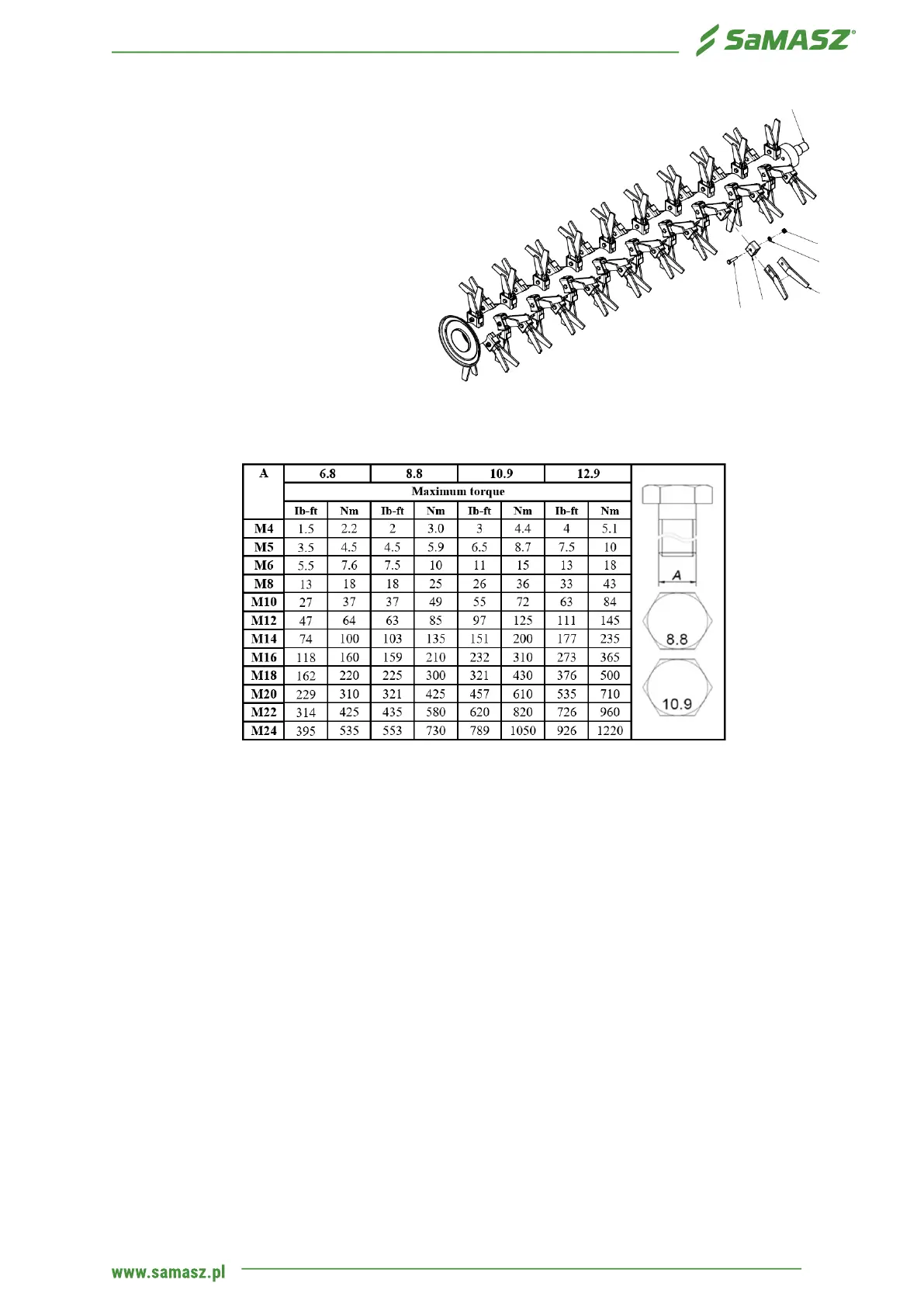

Tab. 5. Torque values for bolts

In the absence of specific torque values, the following chart can be used as a guide to the

maximum safe torque for a particular size and grade of fastener. There is no torque difference for fine

or coarse threads. Torque values are based on clean, dry threads. Reduce value by 10% if threads are

oiled before assembly.

6.10. Adjusting force of the prssure of roller conditioner

(Models: KDT 220 W and KDT 260 W)

With factory set rollers, a ridge on one roller should enter a groove on the other. Clearance between

a ridge and a groove on rollers should be within 2-5mm.

If need be, the force of the roller conditioner’s pressure can be regulated by changing the tension

of springs S (Fig. 33) by means of the nut N. Adjustment should be done on both sides of

the conditioner

Loading...

Loading...