DS 3.401 4 - 10 11/99

OPERATION

WHEN ACTUATOR IS OPERATING BEWARE OF TRAPPING

FINGERS ETC.

The stroke of the 'AL' Linear Actuator is self-setting, using load-

dependent switches, and is determined by the stroke of the valve. The

ALE requires only a simple adjustment. Consequently, all

specifications of actuator are universal and can be fitted to any seat

valve having a stroke length within its nominal range, see details under

'Specifications' on page 2 and 'Valve Stroke Time' on page 3.

The drive can be disconnected for manual operation. A button located

on the top surface of the enclosure is connected to a spring loaded

push rod assembly. When depressed this moves the 2nd gear out of

mesh, this mechanism can be locked in place by moulded ledges in the

housing. Adjacent to this is a manual operation key, which is clipped in

place on the top surface of the enclosure. The key can be fitted into a

slotted feature in the end of the main drive shaft, which protrudes

through the top surface of the enclosure. With the drive shaft

disconnected from the gearbox/motor the manual operation key can be

used to provide manual operation of the actuator.

ALM and ALX Actuators

The load-dependent switches perform a combined limit and transfer

function. The limit switches de-energise the actuator at the end of

stroke, whilst the transfer switches are used basically for sequence

operation in multi-stage applications. Where additional switching or

interlocking functions are required, use the add-on auxiliary switch

accessory or built-in auxiliary switch detailed under 'Specifications'.

When energised between terminals 1 and 3, the actuator moves its

spindle towards the fully extended position, to open a Satchwell 2-port

or 3-port valve to the heat exchanger.

Conversely, when energised between terminals 2 and 3, the actuator

moves its spindle towards the fully retracted position, to close the

valve.

The load-dependent limit switches transfer the control signal from

terminal 1 to 1T and from terminal 2 to 2T at the respective limits of

valve stroke.

ALE Actuators

The ALE incorporates an electronic positioner and provides

modulating control from any controller having a 0-10Vdc output. Using

the 'START' and 'SPAN' adjustments, the actuator can be set to make

a complete stroke over any span from 4 to 10 volts, starting at any point

within the signal range, providing the sum of 'START' Volts plus 'SPAN'

Volts does not exceed 10. The load-dependent limit switches operate

basically as described for the ALM and ALX, but are internally

connected between the electronics card and the motor windings.

Where additional switching or interlocking functions are required, use

the add-on auxiliary switch accessory or built-in auxiliary switch

detailed under 'Specifications'.

A separate 0-10Vdc output is available (terminal 11) for indicating

actuator position to a Building Management System or as a Service

and Commissioning aid.

ALE actuators can be set to operate a low hysteresis when used for

tight control applications on microprocessor based controllers. The

hysterisis is set by using a jumper link on the actuator PCB (see the

commissioning section for details). A low hysterisis setting gives 200

steps between 0 and 10Vdc input and the standard setting gives 25

steps.

The following adjustments are made on the electronic printed circuit

board, accessible behind the removable front cover.

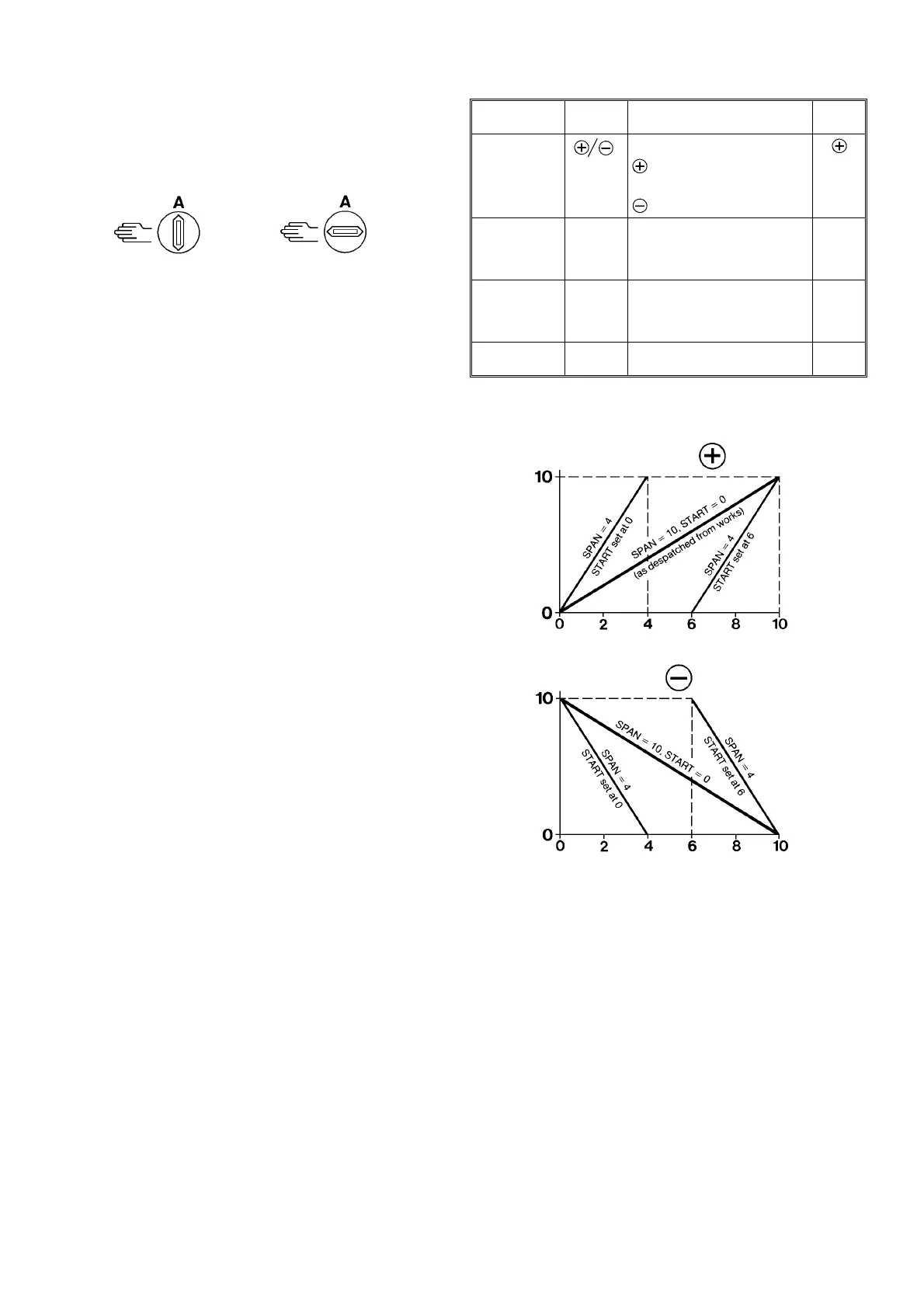

ALE ACTUATOR POSITION FOR TYPICAL SETTINGS OF 'START',

'SPAN' AND 'ACTION'

AUXILIARY SWITCHES

An auxiliary switch kit 831-1-211, comprising two single-pole

changeover switches, is available as a separate accessory. The two

electrically-separate switches can be independently set, one to

operate at any point between positions 0 and 5 and the other between

positions 5 and 10.

(Not applicable to ALX 1251 or ALE 1352, which have one fixed

auxiliary switch built in).

Auto

position

Manual

position

ADJUSTMENT MARKED FUNCTION Factory

set at:

Slide Switch Selects Direct or Reverse Action

signifies increase of actuator

position with increasing input

dc Volt signal.

signifies the reverse of this.

Potentiometer START

(0-10V)

Sets the command signal voltage

at which the actuator

commences to move from zero

position.

0V

Potentiometer SPAN

(4-10V)

Sets the change in command

signal Voltage which will cause

actuator to move through

complete stroke to positing 10.

10V

Potentiometer STROKE Matches operation of actuator to

desired valve stroke.

16mm

Fig.1

Slide switch at

Actuator

Position

Actuator

Position

Slide switch at

Signal Volts

Signal Volts

Loading...

Loading...