DS 3.401 8 - 10 11/99

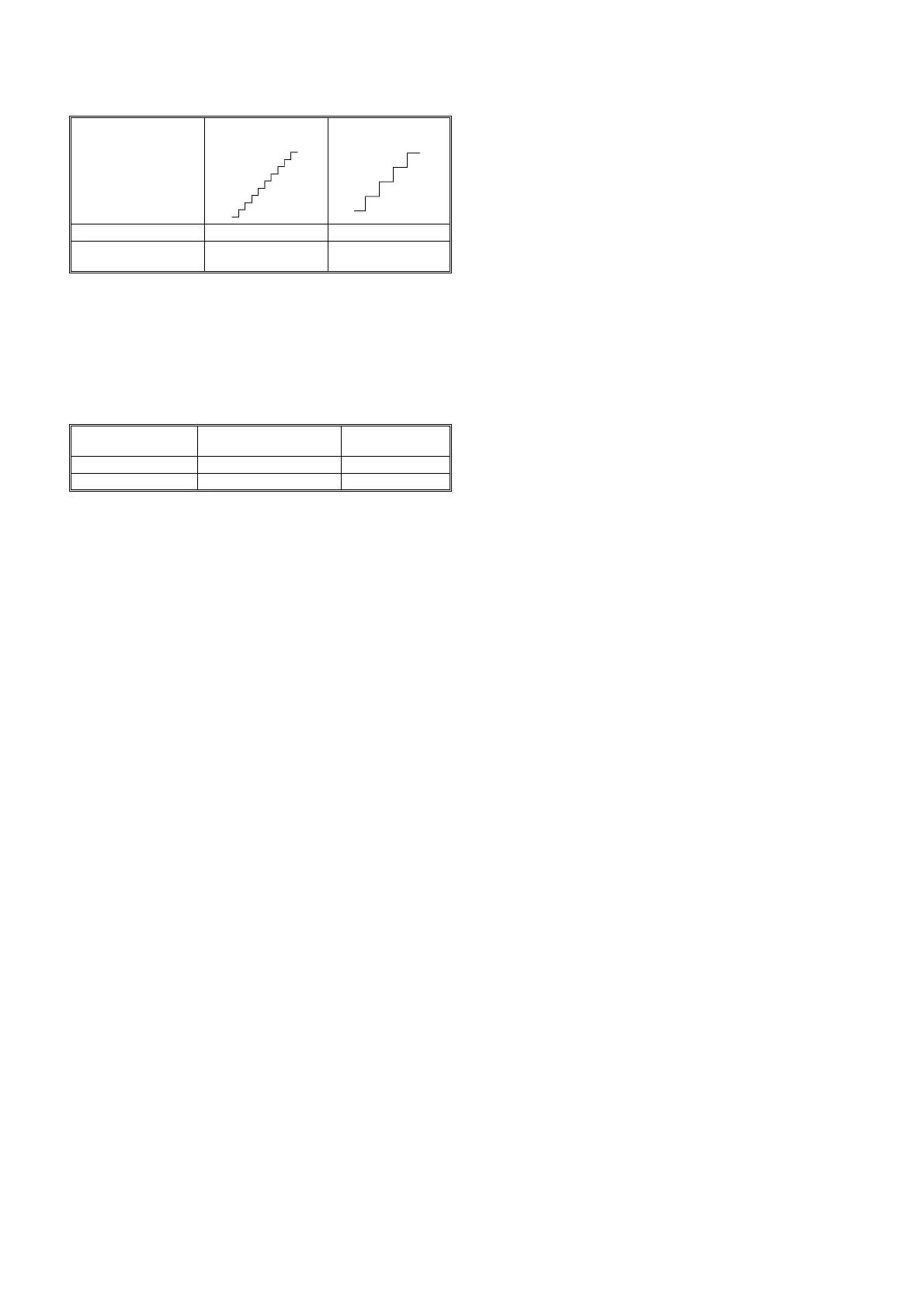

15. Set the required hysterisis for the actuator using jumper 'G'. Low

hysteresis (200 steps) is used for tight control applications using

microprocessor based controllers and standard hysteresis (25

steps) is used for analogue controllers and standard applications.

See the table below for details:-

16. Fit, set and check auxiliary switches, if used, as described for ALM

and ALX (section 9).

17. Replace terminal cover.

ALE WIRING PRECAUTIONS

WARNING -

IF AUXILIARY SWITCHES ARE FITTED AND USED AT MAINS

POTENTIAL, OBSERVE LOCAL WIRING REGULATIONS,

EARTHING REQUIREMENTS AND ALL USUAL SAFETY

PRECAUTIONS.

* When wiring to BAS outstations refer to the appropriate outstation

data sheet for the wiring precautions.

For longer lengths of 24 Volt supply wiring, increase cable size and

observe maximum resistance, also run separate return from terminal 7,

as Fig.12.

Terminals 7 and 10 are both at ground potential, provided for

convenience of wiring.

Where screening is required, use either screened cable, MICC or

cables run in a separate conduit.

Jumper 'G' set to

A-B 200Steps

Jumper 'G' set to

B-C 25Steps

MMC, KMC, IAC, BAS Yes Yes

DRTE, DDTE, DWTE,

CZT

No Yes

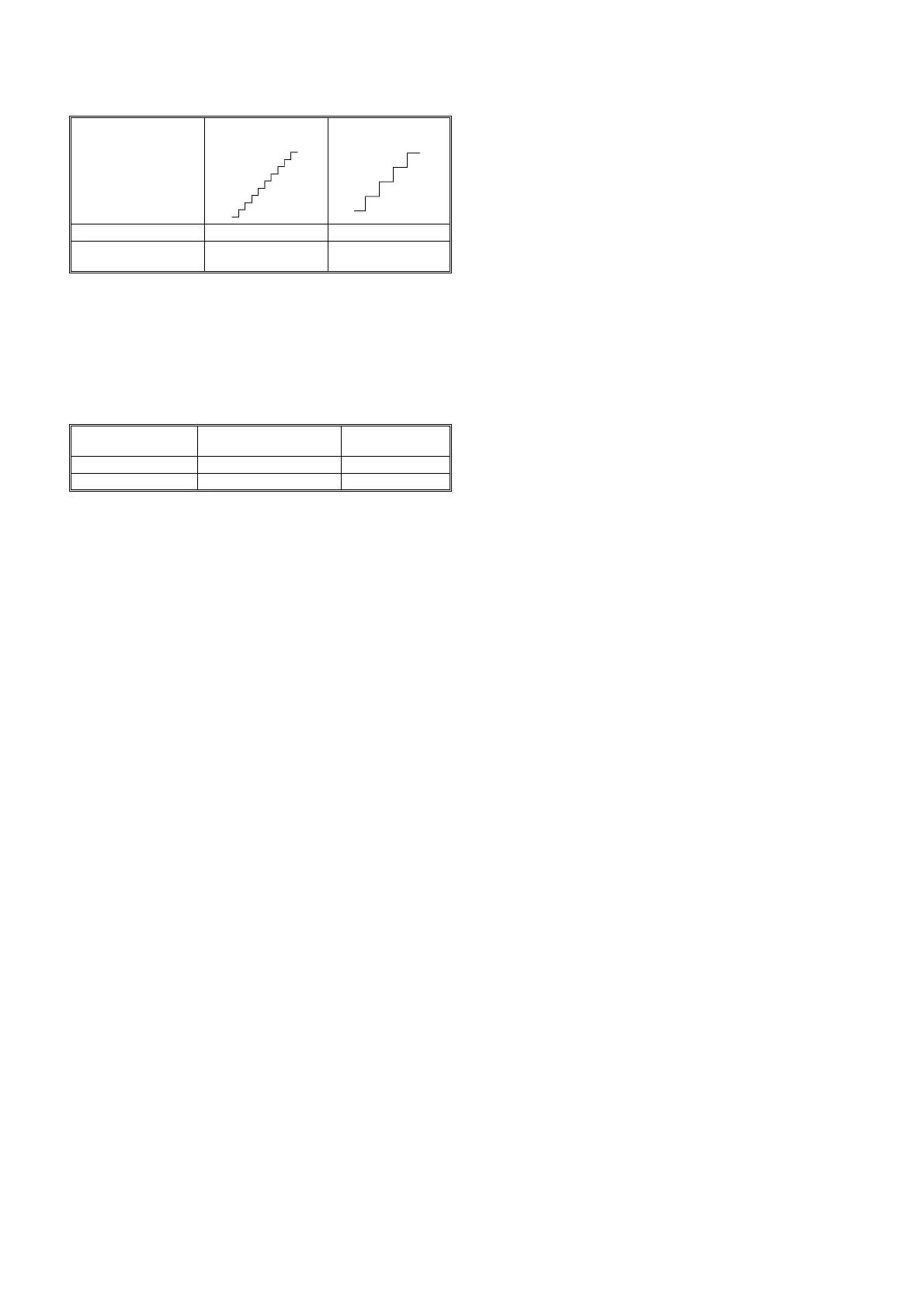

Wiring from actuator

to controller*:

Max. length of 1.5mm²

cable unscreened

Max. resistance

per conductor

24V/240V~ supply 100m 5Ω

0-10Vdc signal 100m 50Ω

10Vdc

0Vdc

10Vdc

0Vdc

Loading...

Loading...