Problem Possible Cause Action

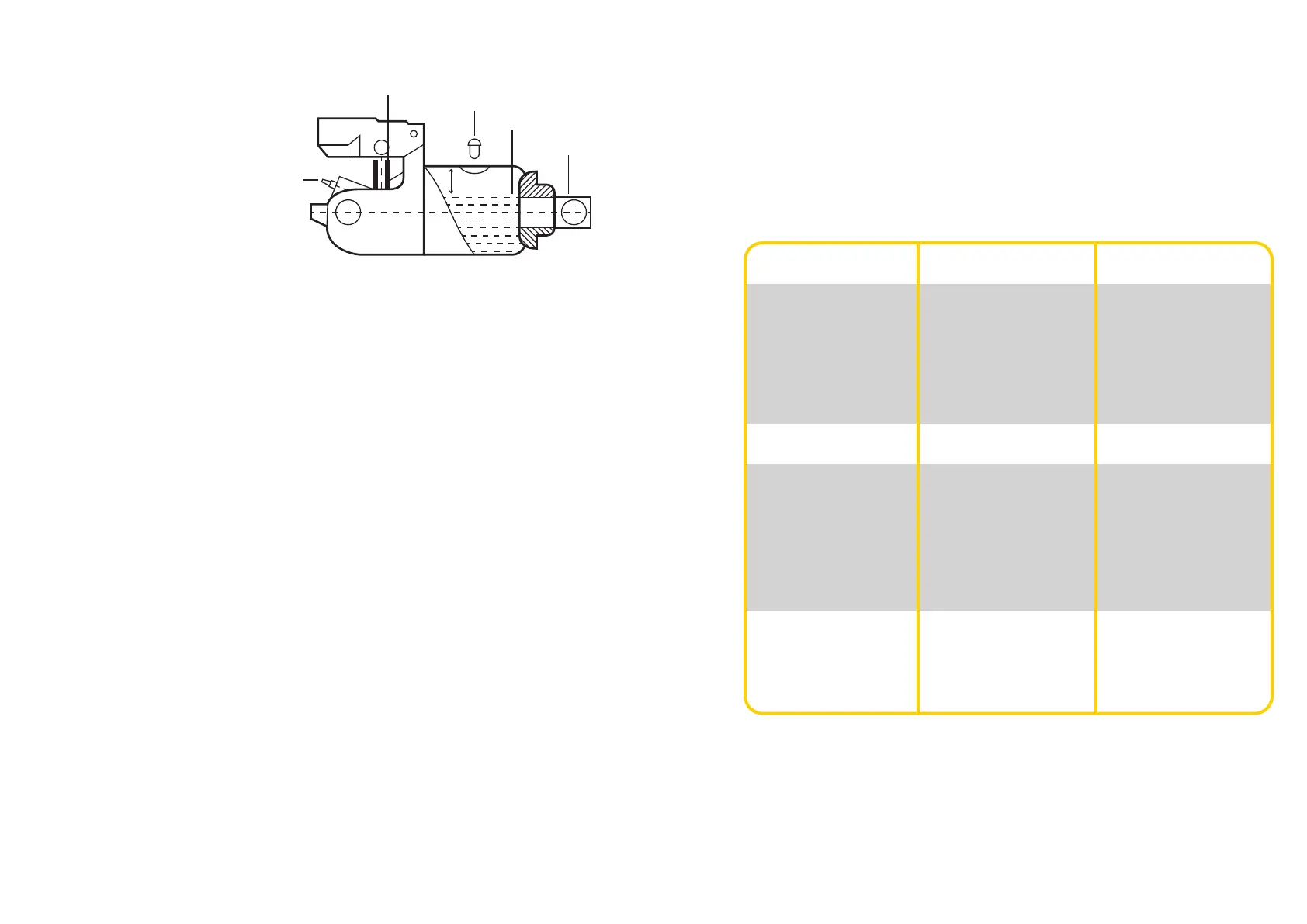

CHECK THE OIL LEVEL

1. Turn the release valve counter clockwise

(Fig 3) to allow the ram to fully retract. It may be

necessary to apply force to the saddle to

lower the ram

2. Remove the inspection plate

3. With the jack in the level position

remove the oil fill plug. Stand the

jack in the vertical position with

the handle socket down. The oil

should be level with the bottom

of the fill hole (Fig 1). If not, top

up but do not overfill. Always fill with new, clean hydraulic jack oil, grade SAE10.

4. Replace fill plug and inspection plate

5. Check jack operation

6. Purge air from the system as required

LOWERING A VEHICLE

1. Turn the release valve clockwise (Fig 3) to the closed position

2. Pump the handle (Fig 2) to lift the vehicle off the jack stands

3. Remove the jack stands. Do not get under the vehicle whilst the vehicle is being lowered

4. Turn the release valve slowly counter clockwise (Fig 4) to lower the vehicle onto

the ground

REPLACING THE OIL

Better performance and longer life of components will be achieved by renewing the oil supply at

regular intervals. To drain the oil, remove the oil filler plug and the release valve. The unit can now

be drained. Great care should be taken to avoid contaminating the system with dirt or grit.

Replace the release valve and refill the reservoir so that oil covers the flat plate visible through

the oil filler hole. Bleed any trapped air in the system as described in the ‘system air purge’

section.

PLEASE DISPOSE OF YOUR WASTE OIL AT A RECYCLING CENTRE. DO NOT CONTAMINATE

DRAINS AND WATERCOURSES OR DISPOSE OF WASTE OIL IN NORMAL DOMESTIC WASTE.

SYSTEM AIR PURGE

1. Turn the release valve counter clockwise (Fig 4) one full turn to open

2. Pump the handle eight full strokes

3. Turn release valve clockwise (Fig 3) to close the valve

4. Pump the handle until the ram reaches maximum height and continue to pump several times

to remove air trapped in the ram (Fig 2)

5. Carefully and slowly pinch the oil fill plug to release trapped air

6. Turn the release valve counter clockwise (Fig 4) one full turn and lower the ram to the lowest

position. Use force on the saddle if necessary

7. Turn the release valve clockwise (Fig 3) to the closed position and check for proper pump

action. It may be necessary to perform the above more than once to ensure all the trapped

air is evacuated

6 7

6.4 mm

Oil Filler Plug

Optimum Oil Level

Hydraulic Ram

Plunger

Release

Valve

Jack will not lift. Lack of oil in system.

Release valve not fully

closed.

Faulty power unit or badly

worn seals.

Check oil. Fill to correct

level, if necessary.

Close the valve tightly.

Service, or change the unit.

Jack lifts but will not

support the load.

Release valve not fully

closed.

Power unit seals worn.

Release valve stuck.

Close the valve tightly.

Service, or change the unit.

Support the load securely &

clean the release valve

assembly.

Jack will not lower. Air in the hyraulic system.

Oil level too high.

Remove the rubber plug,

bleed the system & replace

the plug.

Drain off the surplus oil.

Jack only lifts part way. Low oil level. Fill to correct level.

Loading...

Loading...