ENGLISH

| 112

OWNER’S MANUAL 2021 | ROAD BIKE

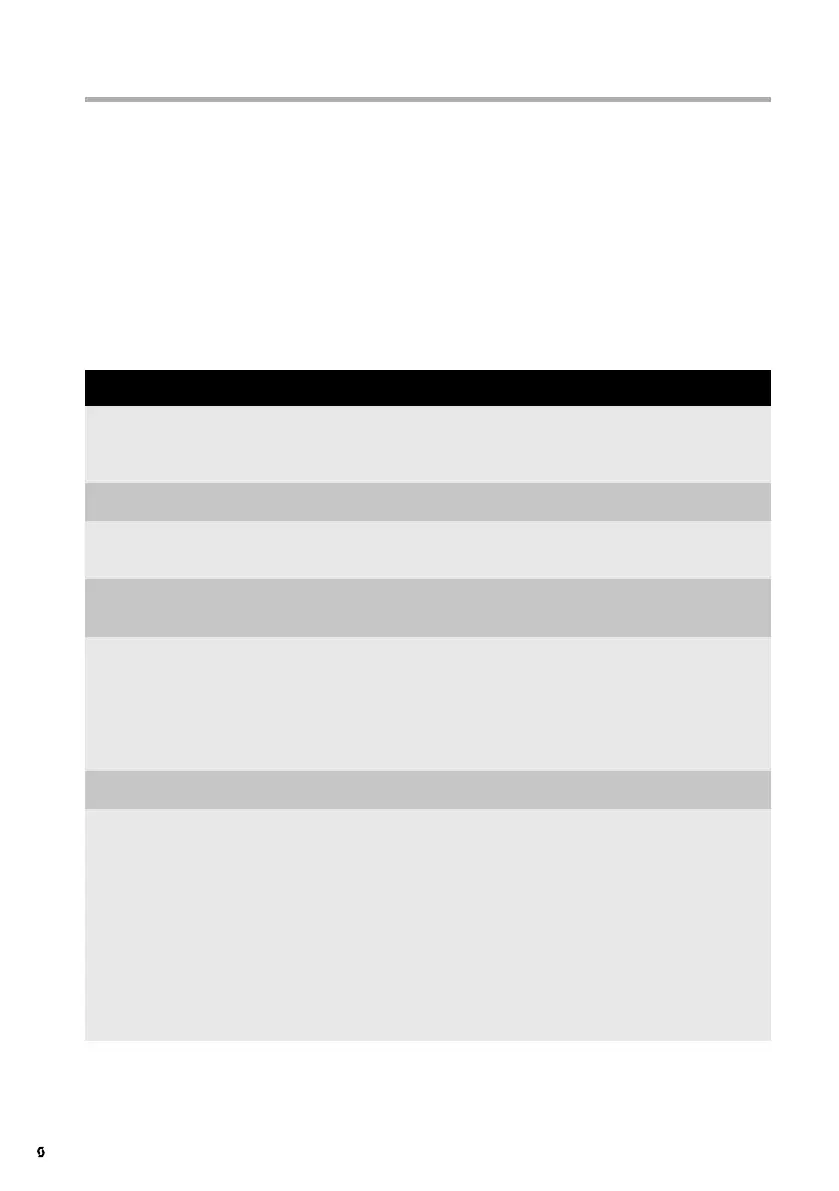

RECOMMENDED TORQUE SETTINGS FOR YOUR SCOTT BIKE

All bolted connections of the bike components have to be tightened carefully

and checked regularly to ensure the safe and reliable operation of the SCOTT

bike. This is best done with a torque wrench that disengages as soon as the

desired torque value has been reached or a click-type torque wrench. Tighten

carefully by approaching the prescribed maximum torque value in small steps

(0.5Nm increments) and check in between the proper fit of the component.

Never exceed the maximum torque value indicated by the manufacturer!

Where no maximum torque setting is given start with 2Nm. Observe the indi-

cated values and observe the values on the components and/or in the manuals

of the component manufacturers.

Component Bolted connections Shimano

1

SRAM/Avid

2

Tektro

3

TRP

4

Campagnolo

5

(Nm) (Nm) (Nm) (Nm) (Nm)

Rear Mount 8 - 10 8 - 12 15

derailleur (on frame/derailleur hanger)

Cable clamp 5 - 7 4 - 5 6

Pulley wheels 3 - 4 2.7

Front Mount on frame 5 - 7 3 - 7 5 - 7

derailleur Cable clamp 5 - 7 5 - 7 5

Shifter Mount on handlebars 5 2 - 5.5 10

Hole covering 0.3 - 0.5

Flatbar 6

Brake Mount on handlebars 4 - 8 3 - 5.5 6 - 8 10

lever unit Time trial brake lever 5 - 7

Flatbar 6

Hub Quick-release lever 5 - 7.5

Lock nut for bearing adjustment

of quick-release hubs 10 - 25

Sprocket cluster lock ring 29 - 49 40 40

(11-speed)

50

(10-speed)

Internal Hub axle nut 30 - 45

gear hub

Crank Crank mount 35 - 50 32 - 38

(grease-free square-head)

Crank mount 35 - 50

(Shimano Octalink)

Crank mount

(Shimano Hollowtech II) 12 - 14

Crank mount (Isis) 31 - 34

Crank mount (Giga X Pipe) 48 - 54

Splined 42

Ultra Torque 42 - 60

Chainring mount 8 - 11 12 - 14 (steel) 8

8 - 9 (alu)

Loading...

Loading...