Temperature Tuning:

1. If when using the pen you see the plastic

bubbling or you hear a crackling noise coming

from the plastic your temperature might be too

high. Try lowering it 5~10°C and see if that helps.

2. Filament should come out smooth and with

out much bubbling but it is normal to have some

small bubbling.

3. While some plastics like PLA are more prone to

oozing, if you nd that your oozing a lot of

plastic you can turn the temperature down on

the pen to help mitigate this. Also check that you

are using the correct lament setting

4. If the lament color looks dim and dark and

you can hear the motor struggling. This means

the temperature is too low increase the

temperature by 5~10°C.

For more help getting started, tips

and tricks, trouble shooting and to

learn more check out our website

www.Scrib3dPen.com or our

youtube channel (scan the QR code).

Troubleshooting:

Problem Reasons Solution

Power indicator

Light will

not turn on

Issue with the AC adapter

or plug

Issue with the electronics

of the pen

Issue with the power socket

of the pen

Replace the AC adapter

with another: 5v, 2A, 3.8mm

barrel center + adapter

The pen’s electronics need

servicing please contact

help@Scrib3Dpen.com if

the pen is under warranty

Nothing is coming

out of the nozzle

The temperature is not high

enough or the wrong mode

for plastic was selected

Check mode the pen is in is

correct of the plastic you are

using. You can also try

adjusting the temp manually

Filament has stripped

ie. a chunk has been

taken out of the lament

and the drive system can’t

push it anymore

Reverse the lament out of

the pen. Cut o the damaged

portion and throw it away

and try again

Filament won’t go in

Make sure the lament has

a at surface on the end

going into the pen

No motor noise

Possible issue with the

electronics or the motor

please contact us at

help@Scrib3Dpen.com

Pen not heating up

Problem with the heating

element/nozzle

Replace the nozzle. See

Scrib3Dpen.com for more info

Motor is struggling

Could be an issue with the

lament inside

Reverse out the lament. Cut

o any swollen or deformed

parts and cut a new end

before reinserting.

"ERR" displayed on

the screen

Temperature is too high for

the mode you are in / or the

nozzle is loose

NOTE: Your pen will go into sleep mode after being inactive

for 5 minuts (as a safety feature). Click any button to wake it

up and restart the heating sequence.

Here are some common problems and possible solutions to

these issue. If you can’t resolve the issue please reach out to

our customer service by email us at help@Scrib3Dpen.com

Snip those tips! When you change plastic or

before you insert a new strand make sure the

lament has a at surface so it can push the

previous lament. Failure to cut the end o

the plastic can result in jams or pens not

extruding. Check out tips on how to solve

such issue on page 6.

We recommend only using the Reverse

button when removing and changing

lament. If only partially withdrawn,

lament can swell in the pen and create

jams. If this happens, fully withdraw the

lament and cut the swollen part o.

Filament quality varies greatly. We

always recommend using Scrib3D

lament, and storing it in a sealed and

dry location.

Plastic may continue to ooze

slightly after the pen stops.

This is more pronounced with

PLA. This is a common

Phenomenon (i.e. glue guns

and 3D printers). If you see this

happening, slightly decrease

the temperature.

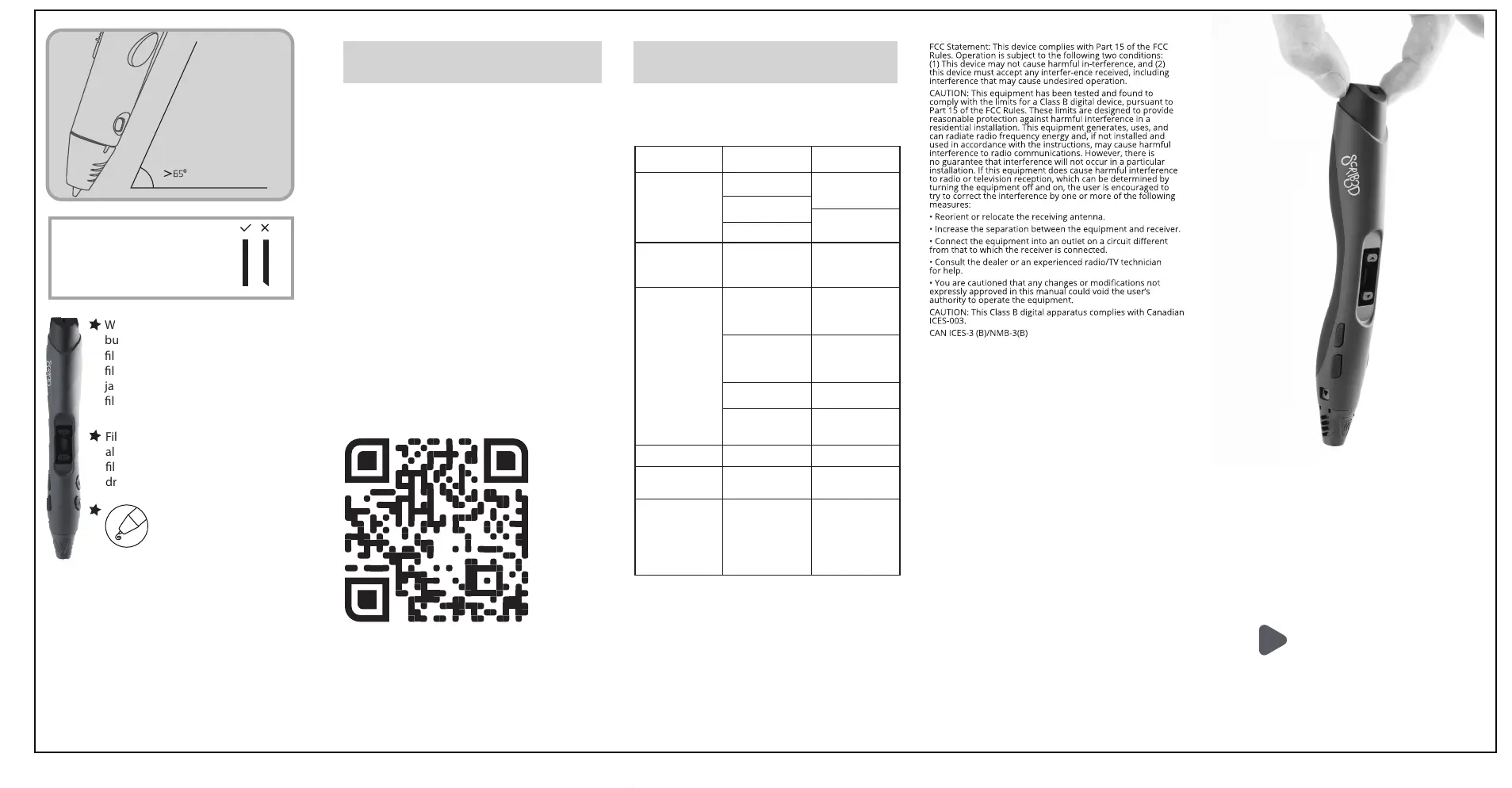

When using your Scrib3D

Advanced 3D Pen you will

nd the best results for

drawing at object and on

surface from holding the pen

at an angle of 65 degrees or

higher.

ISSUES?

Before returning to the

retailer see if we can help

Check out our tutorials:

SCRIB3dPen.com/tips

Need more help? Contact us

help@SCRIB3dPen.com

Unplug the pen and let it

pen cool down for

approximately 3 mins / or

try to push the nozzle back

into place. If issue persists,

reach out to customer

service:

help@scrib3dpen.com

Red and Green

indicator light

ashing

Low-power adapter or

power bank

Change power bank or

adapter to one that has a 2

Amp output

Loading...

Loading...