30

Startup Procedure

Make sure that fuel at the correct pressure is present at the injectors. Turn on ignition and computer

power. Crank the engine, rotate mixture knob richer while cranking. If engine does not fire, see

troubleshooting section. You may also have to increase the START values to get the engine to fire.

Once the engine is running, use the mixture knob to get a smooth idle. Let the engine warm up to

normal operating temperature. Once warmed up, attempt to set the knob near the center position (12

o’clock). To do this will most likely require adjustments to the RPM FUEL values. If the knob is on the

rich side of 12 o’clock, the RPM FUEL values are too low and vice versa.

On F systems, you must set the MAGNET POSITION parameter as soon as the engine is idling

smoothly before performing any other adjustments. Refer to that section of the F manual.

Fine tuning RPM FUEL values

We normally want to aim for around 12 to 1 AFRs and this is best determined using a wideband AFR

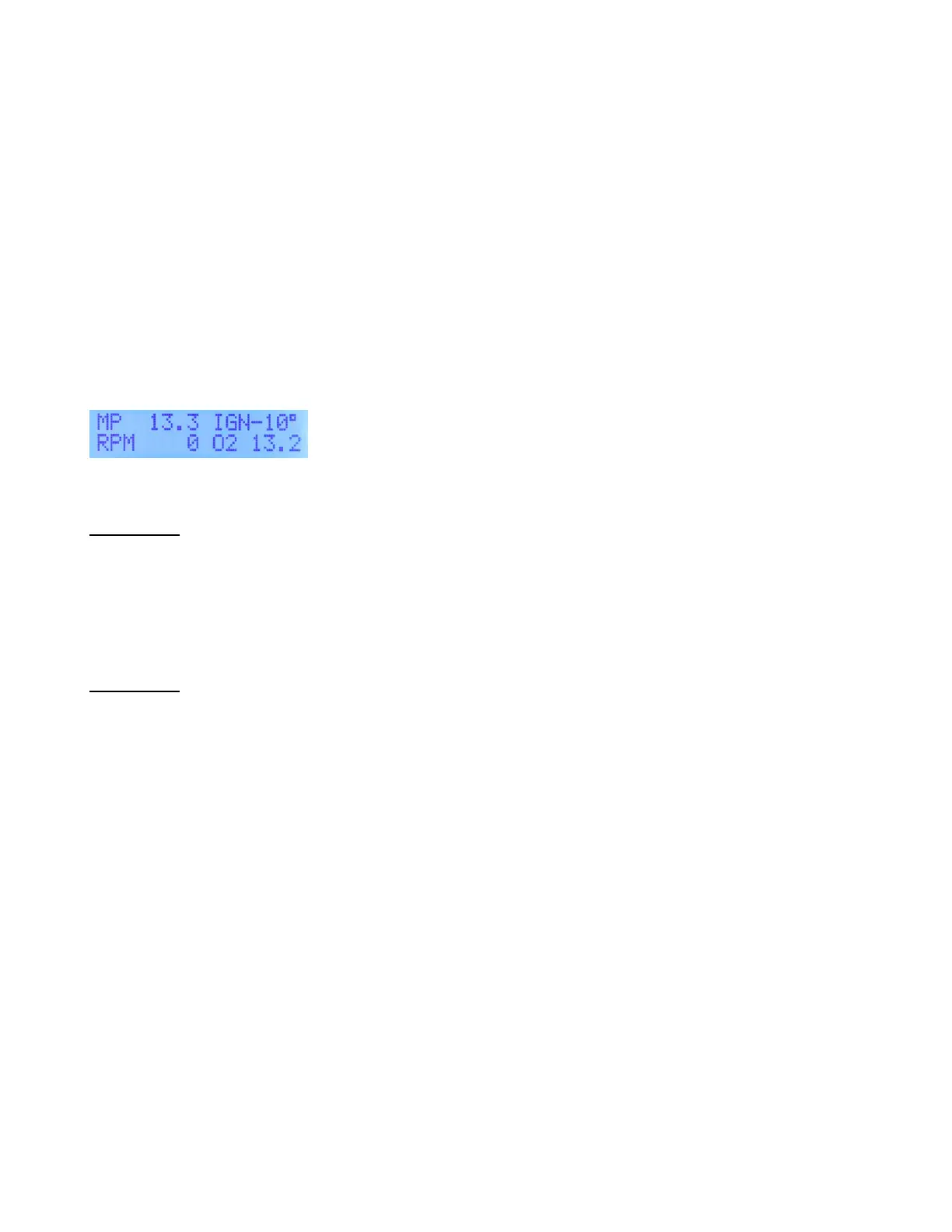

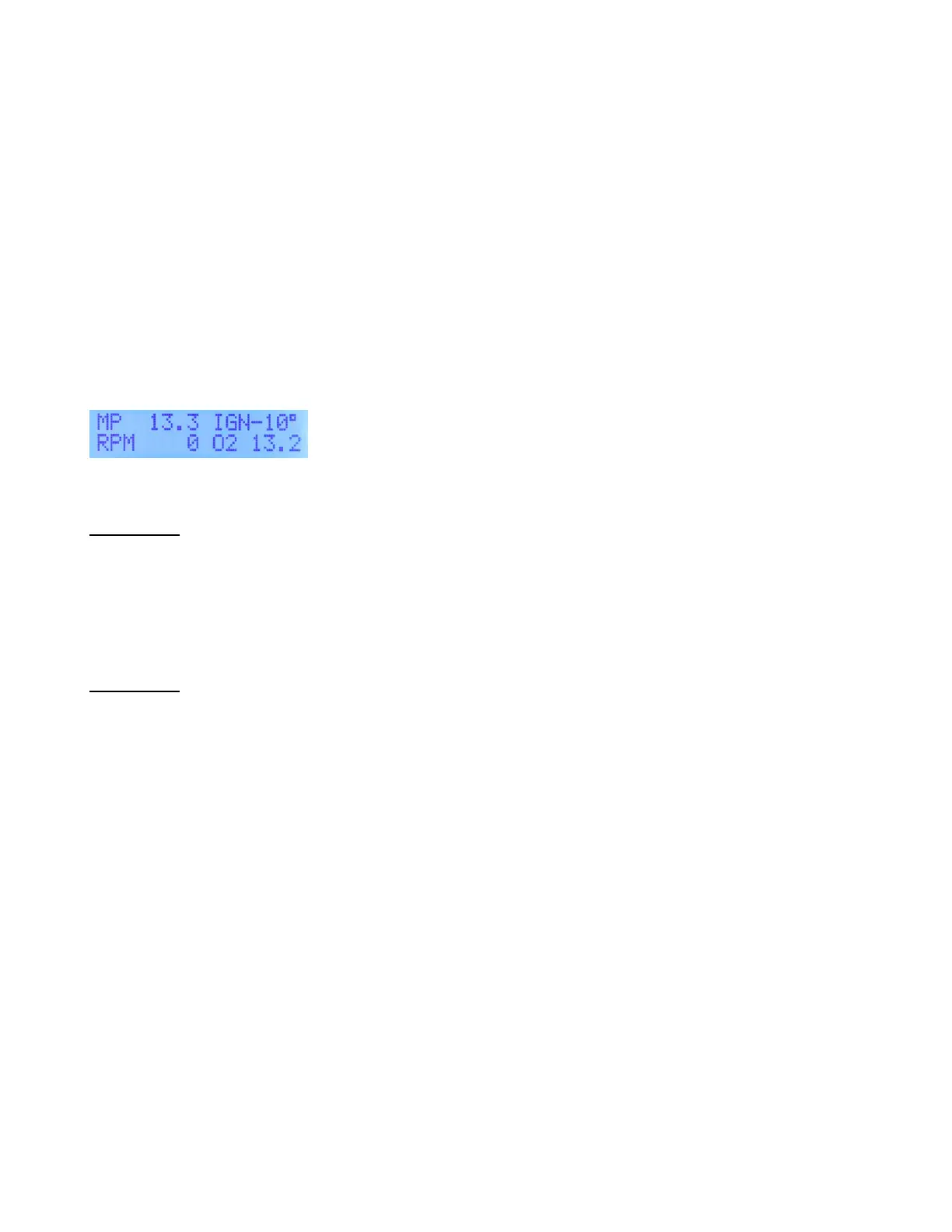

meter. You can read the AFRs in gauge 3 or 4 screens. AFR is displayed as O2 in Gauge 4 as shown

below.

Correcting the Mixture Using a Wideband AFR Meter

Example #1: At 2500 RPM say, we have an RPM FUEL value of 108. The A/F ratio is 14.7, but we

would like to make the A/F ratio 13.5.

Correction=14.7/13.5

Correction= 1.09.

Now we multiply the RPM FUEL value by 1.09.

108 x 1.09=117.7. Round off to 118.

Example #2: At 2000 RPM say, we have an RPM FUEL value of 108. The A/F ratio is 12.5, but we

would like to make the A/F ratio 13.5.

Correction=12.5/13.5

Correction= 0.93

Now we multiply the RPM FUEL value by 0.93.

108 x 0.93=100.44. Round off to 100.

With a wideband sensor, best power will usually occur with an A/F ratio of around 12.5:1, however

automotive type engines may not tolerate running this lean due to piston thermal considerations and

air cooled aircraft engines may not cool sufficiently. We recommend most engines be set up to run

around 11 to 11.5 AFR during high power conditions- WOT, takeoff and climb. See the appropriate

supplemental manual for your engine type for more detailed specific information.

Manifold Pressure, MAP or MP

There are 64 programmable ranges in the manifold pressure chart for adjusting fuel. Data in the

manifold pressure chart determines the relationship intake manifold pressure and the amount of fuel

injected. Aviation EM-5 systems are calibrated in inches of mercury absolute. There are 3 different

MAP sensors used with the system which cover a different range of pressures. All units are pre-

programmed with a standard MAP value chart depending on the MAP sensor used. These values

should be close, so most initial programming is usually done on the RPM FUEL values. MAP values

generally increase in a near linear fashion as manifold pressure increases. Your MAP values

should never go up and down like a sawtooth!

Loading...

Loading...