•

FIGURE

33

WASHER

,,

KLIP RING

FIGUFIE

35

FIGURE

36

._

____________________________

...

·

12

·

5.

BELT

REPLACEMENT

The be

lts

on this

tractor

are

special

for

this application,

when replacing Belts always replace

with

Sears

belts.

a. Disconnect Battery, Negative Ground Cable.

b.

Set

Parking Brake (Fig. 10).

c.

Pull Varidrive Control L

eve

r

to

s

low

position (Fig. 11)

giving

Pr

imary

Be

lt slack.

d. Remove Primary

Be

lt

from Engine Pulley (Fig. 34).

e.

Remove 3 Bolts and Nuts holding Primary Idler

Sheaves

to

Frame (Fig. 33).

f.

Remove

Klip

Ring and Washer

from

Variator

Pivot

Shaft

(Fig. 34). Slide P

ivot

Arm inwards.

g.

Remove

Be

lt

from

Variator

Sheave.

h. Remove Id

ler

Nuts and Idler

Sheaves

from

Primary Idler

Sheaves

(Fig. 34).

i.

Primary (Front) Belt can

now

be

removed.

j.

To

replace Secondary (Rear) Belt move

Varid

rive Con·

trol

Lever

to

fast position. Remove Variator

Be

lt

Keeper

(Fig. 34) and remove Secondary

Belt from Variator.

k.

Rem

ove

Clutching

Id

ler

(Fi

g.

34).

I.

Remove Transmission Pulley B

elt

Guard. Belt can

now

be

removed from Transmission Pulley.

m.

Reverse

the above procedures

to

install

ne

w

Be

lts. Re·

place Primary Idler

Package,

Belt

Keeper, Clutching

Idler

and Transmission Pulley

Be

lt

Guard.

n. Connect Battery.

NOTE:

WH

EN A NEW

BELT

OR BELTS

ARE

INSTALL

·

ED, YOU MUST CHECK

BELT

ADJUSTMENT. REFER

TO

"CHECK

BELT

ADJUSTMENT",

PAGE

7.

6.

CL

EAN

BATTERY

AND

TERMINALS

Corrosion

an

d d

ir

t on the Battery and Terminals

cause

the

Ba

ttery

to

"leak"

power and hinders

th

e operation

of

th

e charger.

a.

Rem

ove

the Battery from the Tractor and

wash

wi

th

four

tablespoons

of

baki

ng

soda

to

o

ne

ga

llon

of

water.

NOTE:

BE

CAREFU L

NOT

TO GET

THE

SODA

SOLUTION

IN

TO

THE

CELLS

. Rin

se

the Battery

with

plain wate

r,

dr

y and reinstall on Tractor.

b.

Clean termin

als

and cable ends

with

a wi

re

bru

sh

until

bright. Replace Battery

Cables.

Coat terminal connec·

ti

ons

wi

th

Vasol

i

ne.

7.

TI

RE CARE

a.

Maintain tire pr

ess

ur

e in

front

at 14 pounds

and

rear ti

res

at 10 pounds.

· b. Keep tires free

of

gasoline, oil,

or

insect

control

chemi·

cals

whi

ch

can

destroy rubber.

c.

Avoid stumps, stones, deep ruts

and

other hazards

that

may

cause

ti

re

damage.

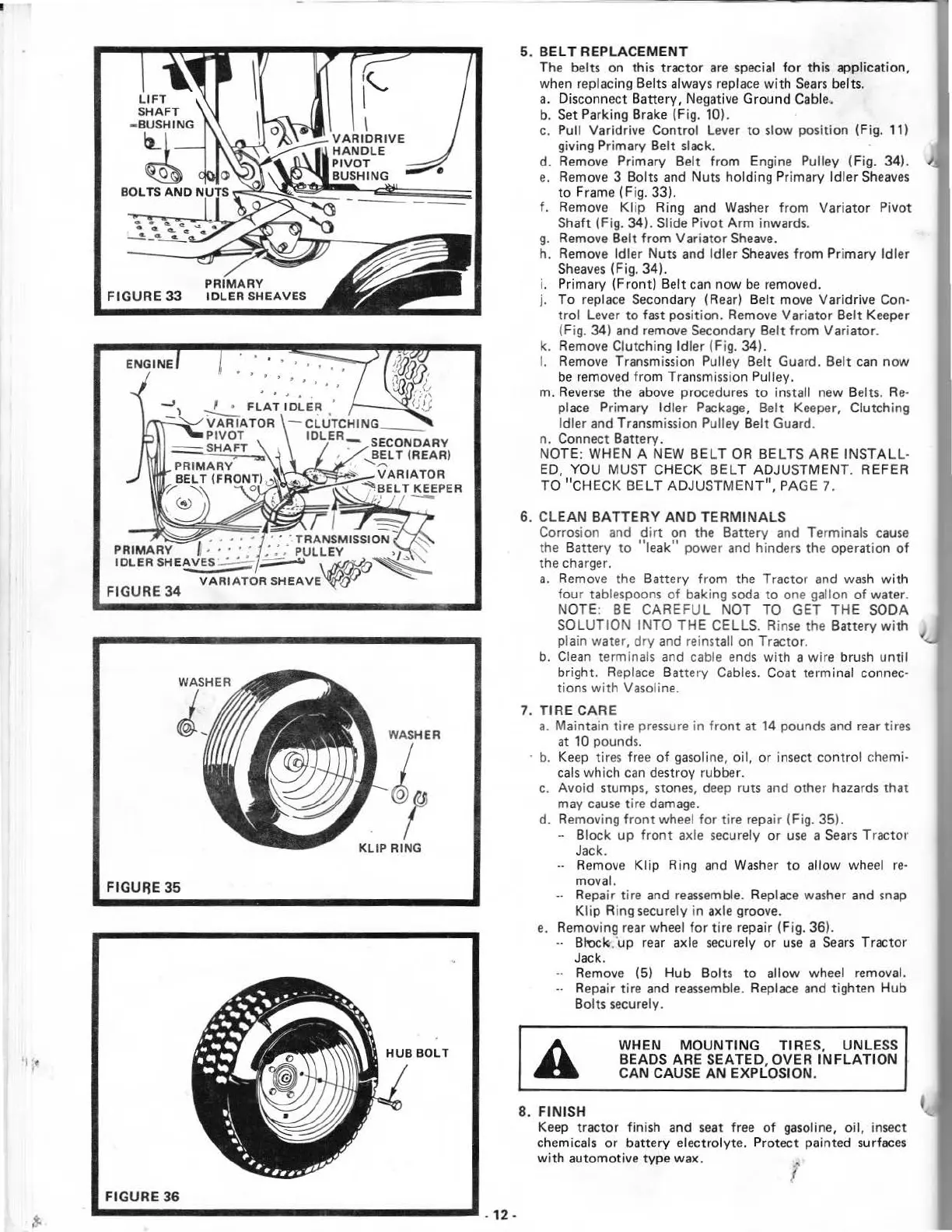

d. Removing

front

wheel

for

ti

re

repair (Fig. 35).

Block

up

front

axle securely or

us

e a S

ears

Tractor

Ja

ck.

··

Remove

Klip

Ring

and

Washer

to

allow wheel

re·

moval.

··

Repa

ir

tire and

reassemble.

Rep

lace

wash

er and

snap

Klip

Ring securely in

ax

le groove.

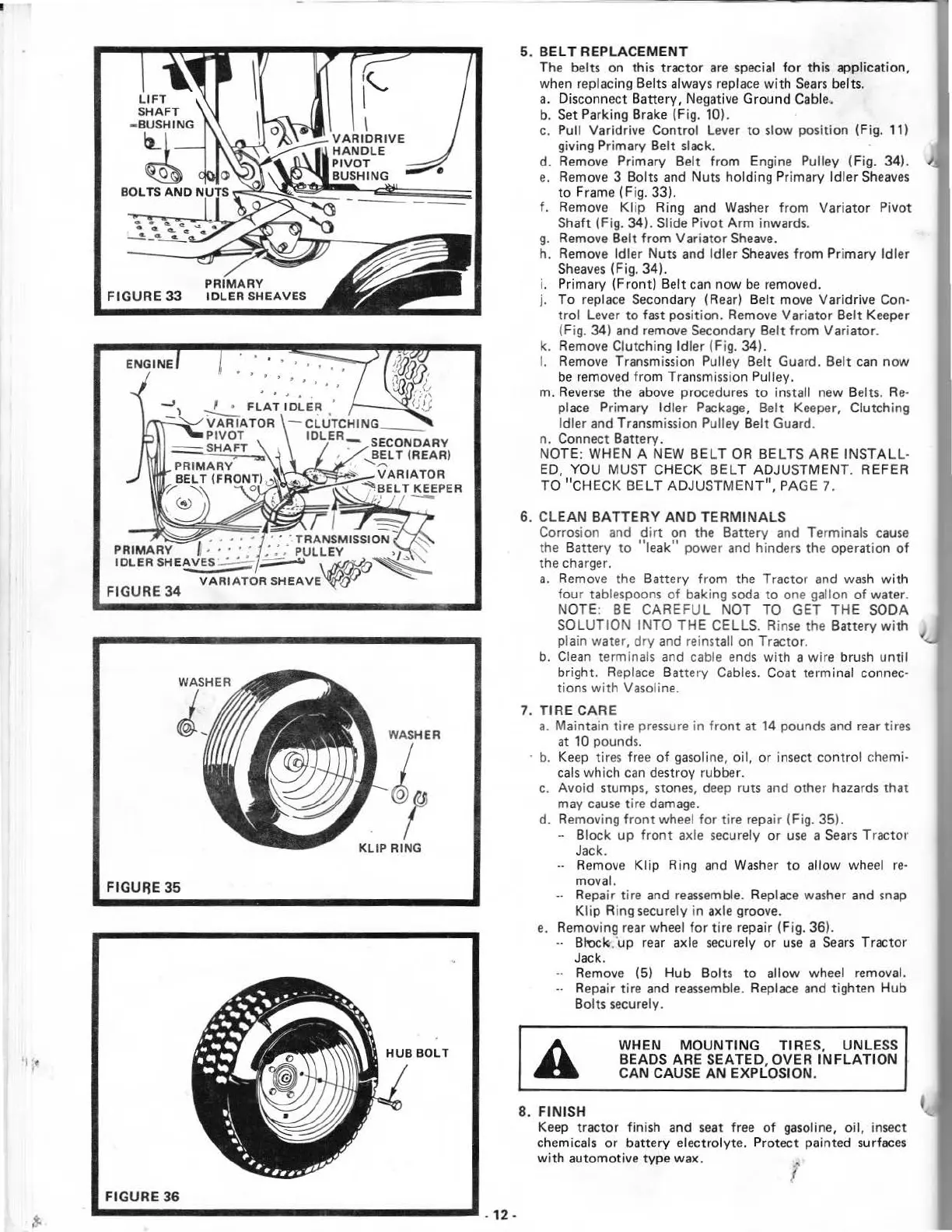

e. Removing rear

wheel

for

tire repair (Fi

g.

36

).

..

BI'Ock

: up rear axle securely

or

use

a

Sears

Tractor

Jack.

.. Remove (5) H

ub

Bolts

to

allow wheel removal.

..

Repai r tire and

rea

ssemble

. Replace

and

tighten Hub

Bolts securely.

8.

FINISH

WHEN

MOUNTING

TIRES, UNLESS

BEADS

ARE

SEATED,

OVER

INFLATI

ON

CAN CAUSE

AN

EXPLOSION.

Keep

tr

actor finish and seat free

of

gasoline, oil, insect

chemica

ls

or

battery electrolyte. Protect painted surfaces

w

ith

automotive type wax.

/

another free manual from www.searstractormanuals.com

Loading...

Loading...