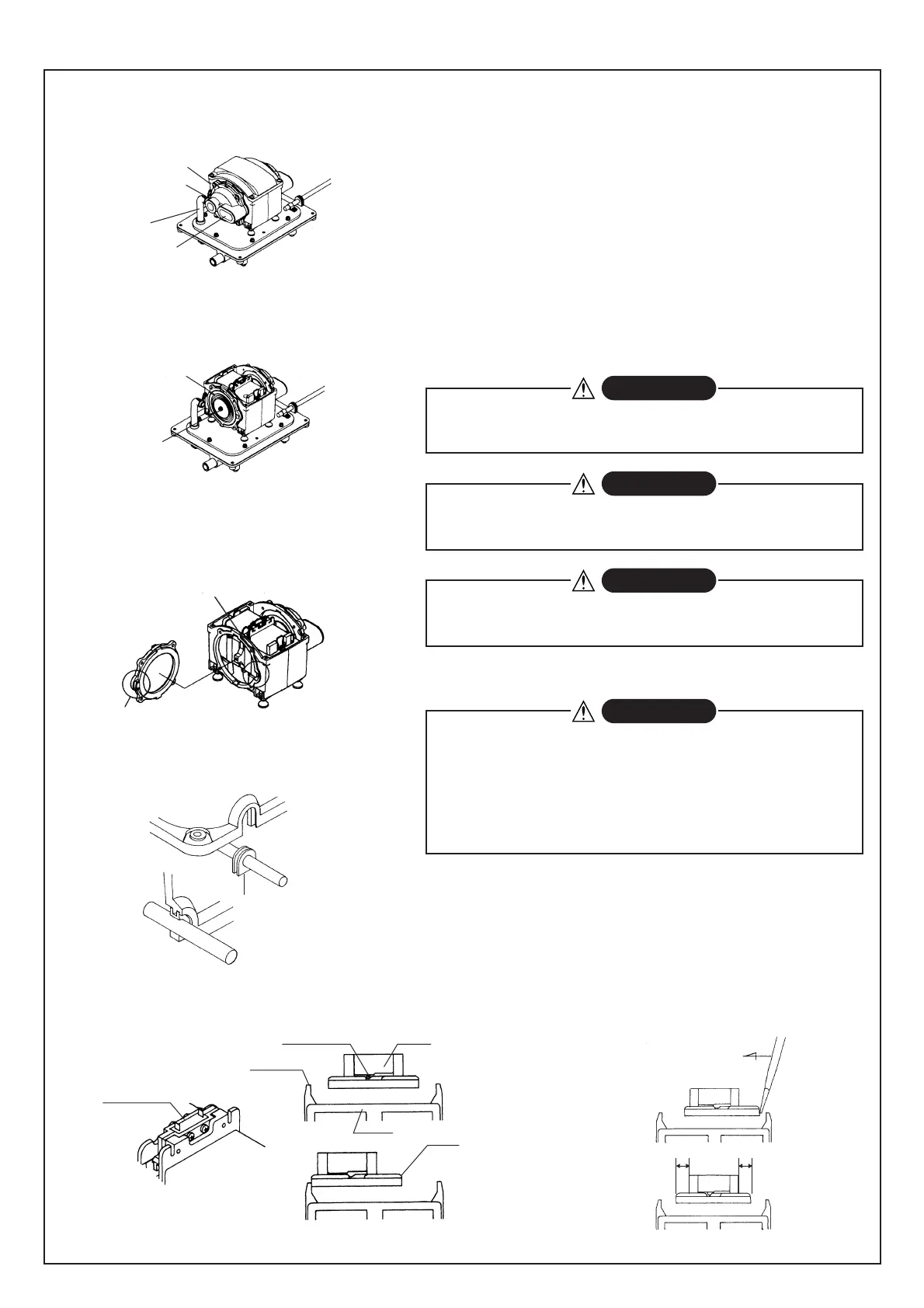

3 Reset of auto stopper

If the diaphragm is broken, the magnet reciprocates with

abnormal amplitude and the projection hits the slider. The

contact is interrupted and power is off

(

Ref. : Fig. 11

)

.

- Insert a slotted screwdriver and push the slider.

- Set the slider at the position L1=L2

(

Ref. : Fig. 12

)

.

- If the magnet contacts the solenoids during operation, it will

cause damage on parts, abnormal heat, and short circuiting.

WARNING

- Do not touch live parts. Touching live parts will result in

electric shock.

DANGER

- Improper setting of the rubber bushing can result in electric

shock, airleakage.

CAUTION

- Disconnect the power before servicing.

Do not touch the terminal of the switch. If hazard is ignored,

electric shock is possible.

If not disconnected, the magnet starts moving upon reset of

auto stopper.

Personal injury is possible.

DANGER

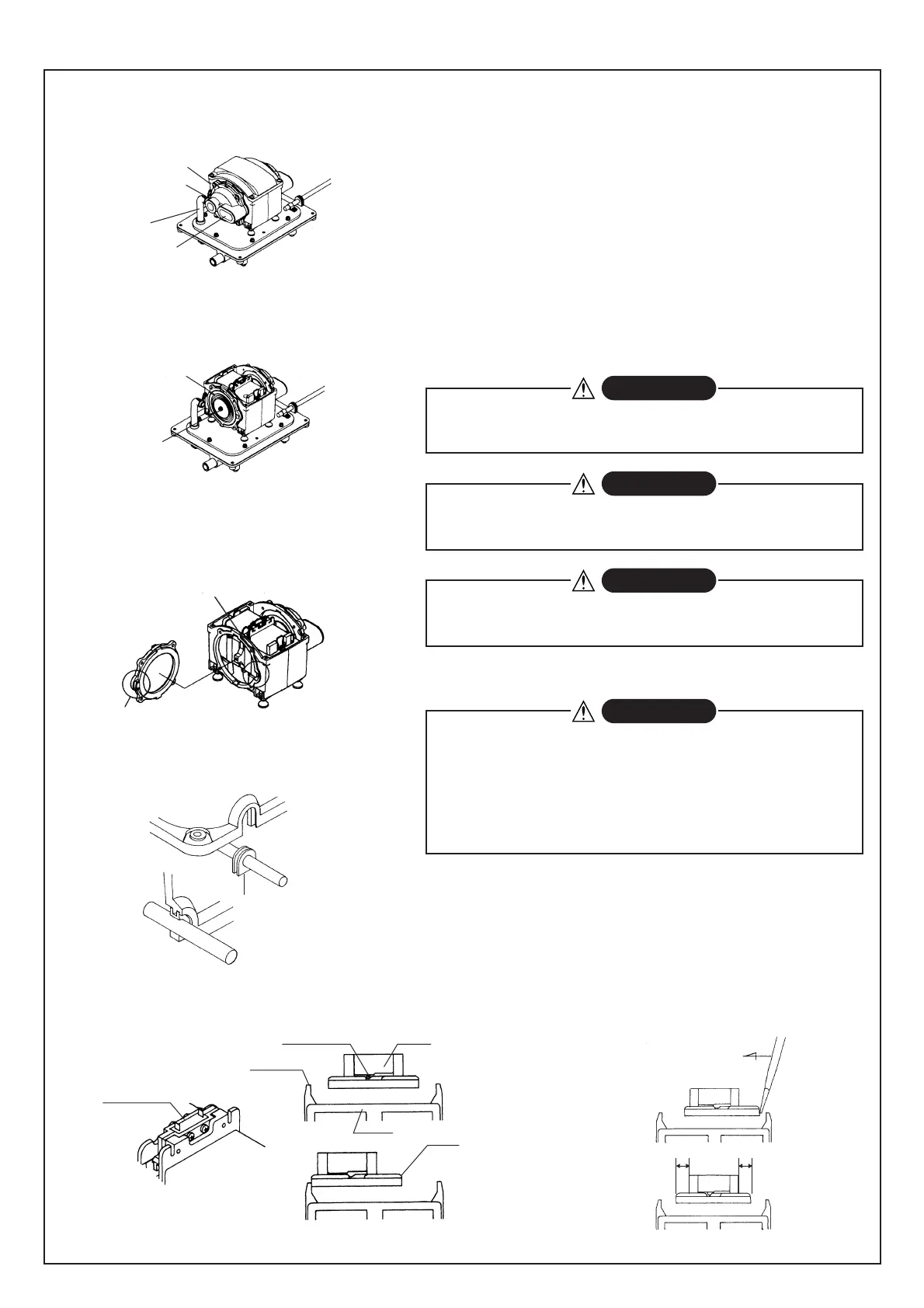

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11 Fig. 12

- Connect the exhaust port of the valve box with the connecting

pipe and tighten it with the hose clamp securely

(

Ref. : Fig. 7

)

.

- Reset the auto-stopper, if necessary

(

Ref. : 3 Reset of auto-stopper

)

.

- Connect power and confirm the operation.

- Fasten the holder cover with the four corner screws

(

B

)

and

put the shock absorber back into place

(

Ref. : Fig. 4

)

.

- Put the overall cover, inserting the power cord rubber bushing

into the location notch of the overall cover

(

Ref. : Fig. 10

)

.

- Fasten the overall cover securely by the nuts and bolts.

Diaphragm

holder

Locating notch

Inlet

(

D

)

Screw

(

C

)

Hose

clamp

Valve

box

Connecting

pipe

Contact point Switch

Projection

Magnet

Slider

L1 L2

Rubber

bushing

Auto stopper

Loading...

Loading...