8

8. MAINTENANCE - SAFETY VALVES

The Pressure (expansion) Relief Valve and, if fitted, the Temperature/Pressure Relief

Valve should be regularly checked. Manually operate the valves by either twisting the

cap or lifting the lever. Ensure water flows freely from the valve(s) and through the

discharge pipes. Ensure the valve(s) reseat correctly when released.

9. MAINTENANCE - EXPANSION VESSEL PRECHARGE

PRESSURE

The Expansion Vessel, if fitted, should have a precharge pressure of 4.1 bar (60 p.s.i.).

This can reduce over time and eventually require re-charging. To do this:

9.1 Turn off water supply to the unit; open a hot tap to relieve system pressure.

9.2 Remove dust cap from top of Expansion Vessel

9.3 Check pre-charge pressure using a tyre pressure gauge. If the pressure is lower

than 4.1 bar (60 p.s.i.) it should be recharged using a tyre pump

(Schraeder Valve type). DO NOT OVER CHARGE.

9.4 Re-check pressure and when correct replace dust cap.

9.5 Turn on mains water supply and close hot tap.

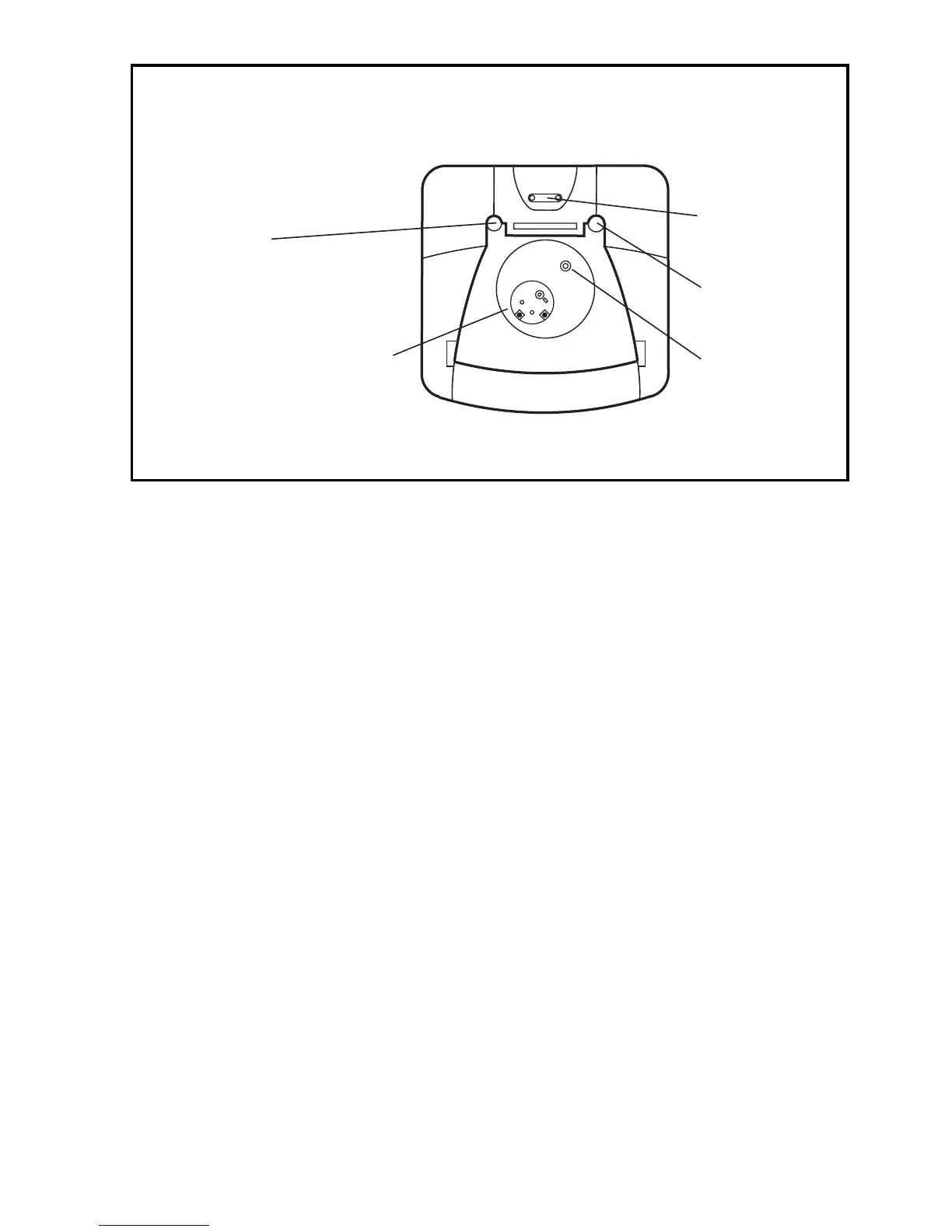

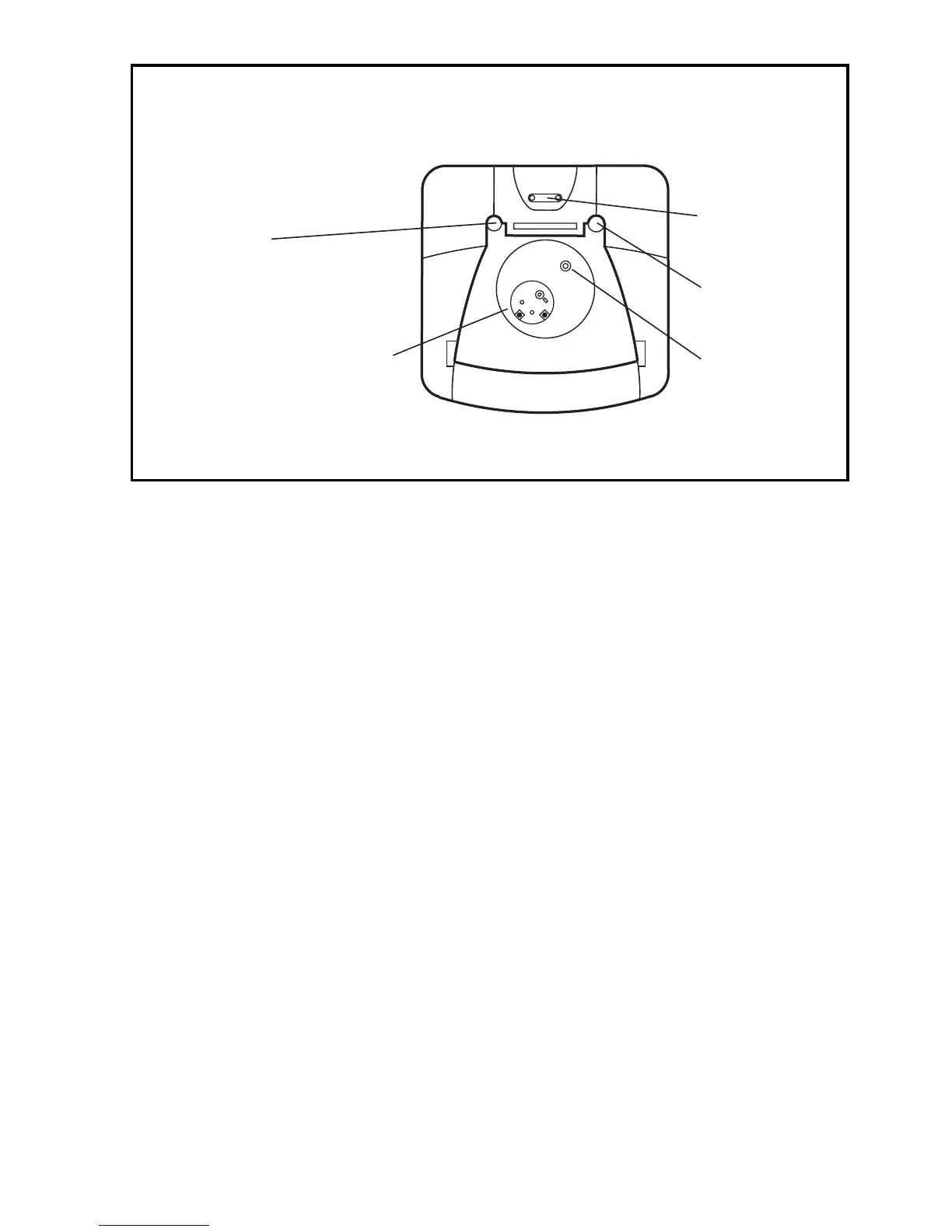

INLET

OUTLET

CABLE CLAMP

EARTH POST

COMBINED THERMOSTAT

AND THERMAL CUT-OUT

FIGURE 7: CORRECT ORIENTATION OF ELEMENT PLATE ( VIEWED FROM TOP OF UNIT ).

Loading...

Loading...