Overcurrent Elements Page 5 of 7 20120723

Validation Pickup Test Values

The instructor will use the SEL-AMS (Adaptive Multichannel Source) to inject secondary quantities into

the relay terminals to simulate faults (as indicated in Table 1).

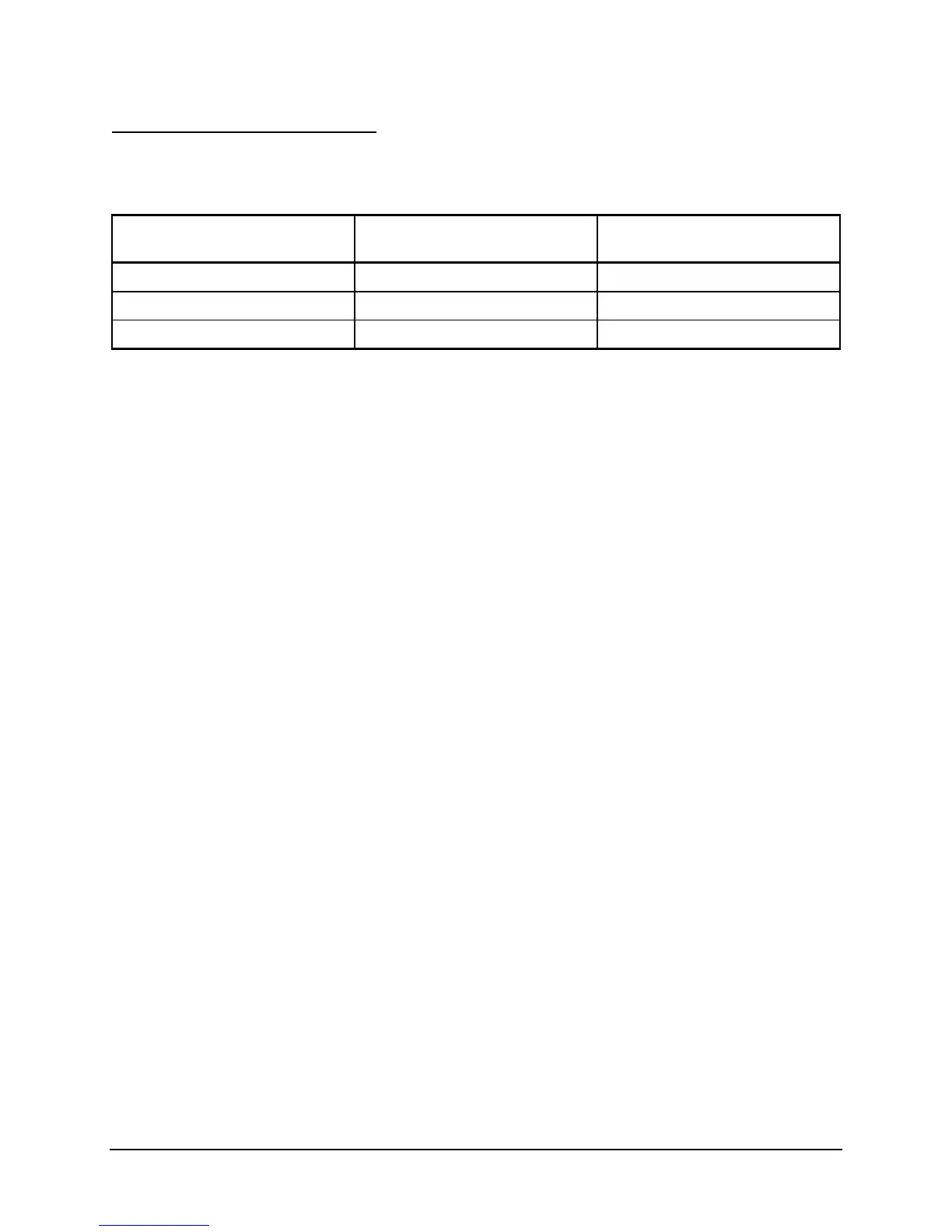

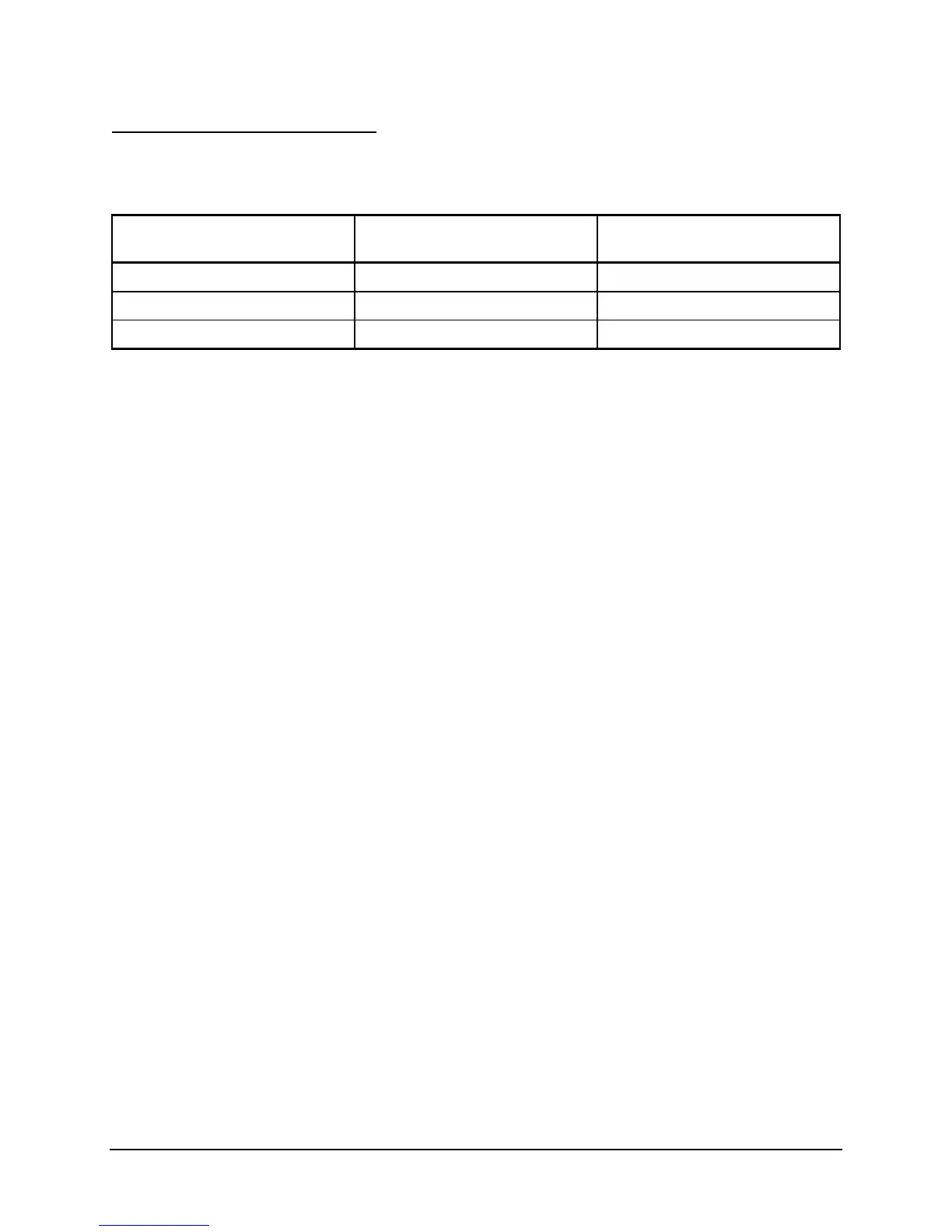

Table 1 Simulated F1 Values for Element Pickup Test

Input

(Fault Applied at F1 Location)

Element Fault

IAW1 51P1P

IAW2 51P2P

IAWn (n = 2 in this example) 50NN21P

The instructor will apply the test values to the relay using the SEL-5401 Test System Software

front-panel

function. Apply a value slightly less than the pickup setting, and slowly increase the current magnitude

until the applicable Relay Word bit asserts.

Step 1

Reset relay targets by pushing the {TARGET RESET} pushbutton located on the relay front panel.

Step 2

Clear the Sequential Events Recorder (SER) entries.

You can perform this task by using either the SER C serial port command or the

ACSELERATOR

QuickSet human-machine interface (HMI).

The instructor will apply the fault current.

Step 3

Use the TARn serial port command (n = the Relay Word bit for the element under test) or the

ACSELERATOR QuickSet HMI to verify the overcurrent element pickup.

Step 4

Verify the following

ACSELERATOR QuickSet HMI user-defined target light-emitting diode (LED)

indicators:

• Phase time-overcurrent element 51P1P asserts.

• Phase time-overcurrent element 51P2P asserts.

• Neutral instantaneous overcurrent element 50NN21P asserts.

Record the element in the “Fault” column of Table 1.

Loading...

Loading...