4

X

SEMPELL SERIES VSE/VSR FULL LIFT AND NORMAL SAFETY RELIEF VALVE

OPERATING INSTRUCTIONS

3.3 Installation instructions

NOTE

Clean pipes before installing safety valves as

otherwise the valve seats can be damaged by

foreign bodies when discharging!

Remove transport protection just before

installation.

Check plant identification and details on the

nameplate.

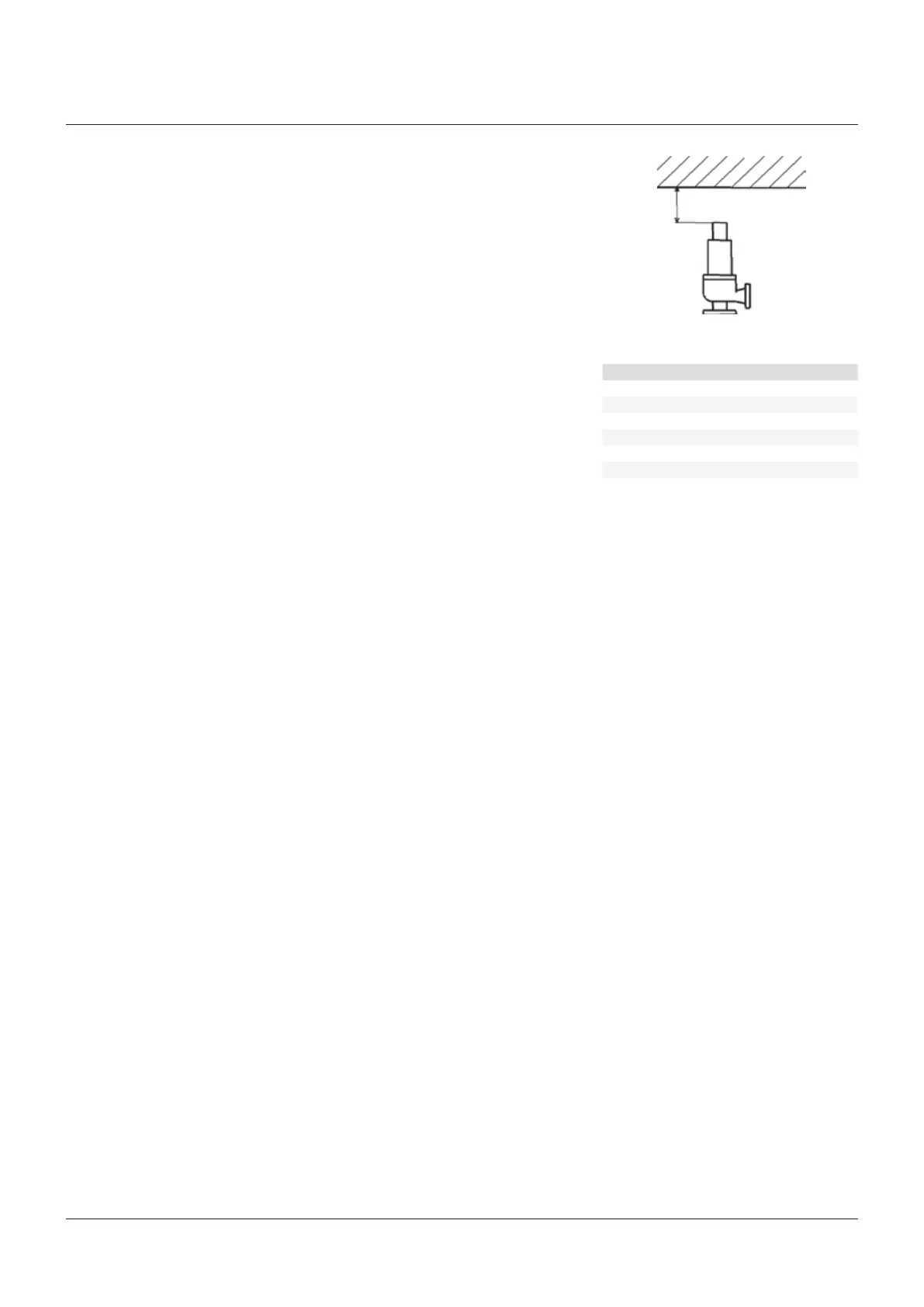

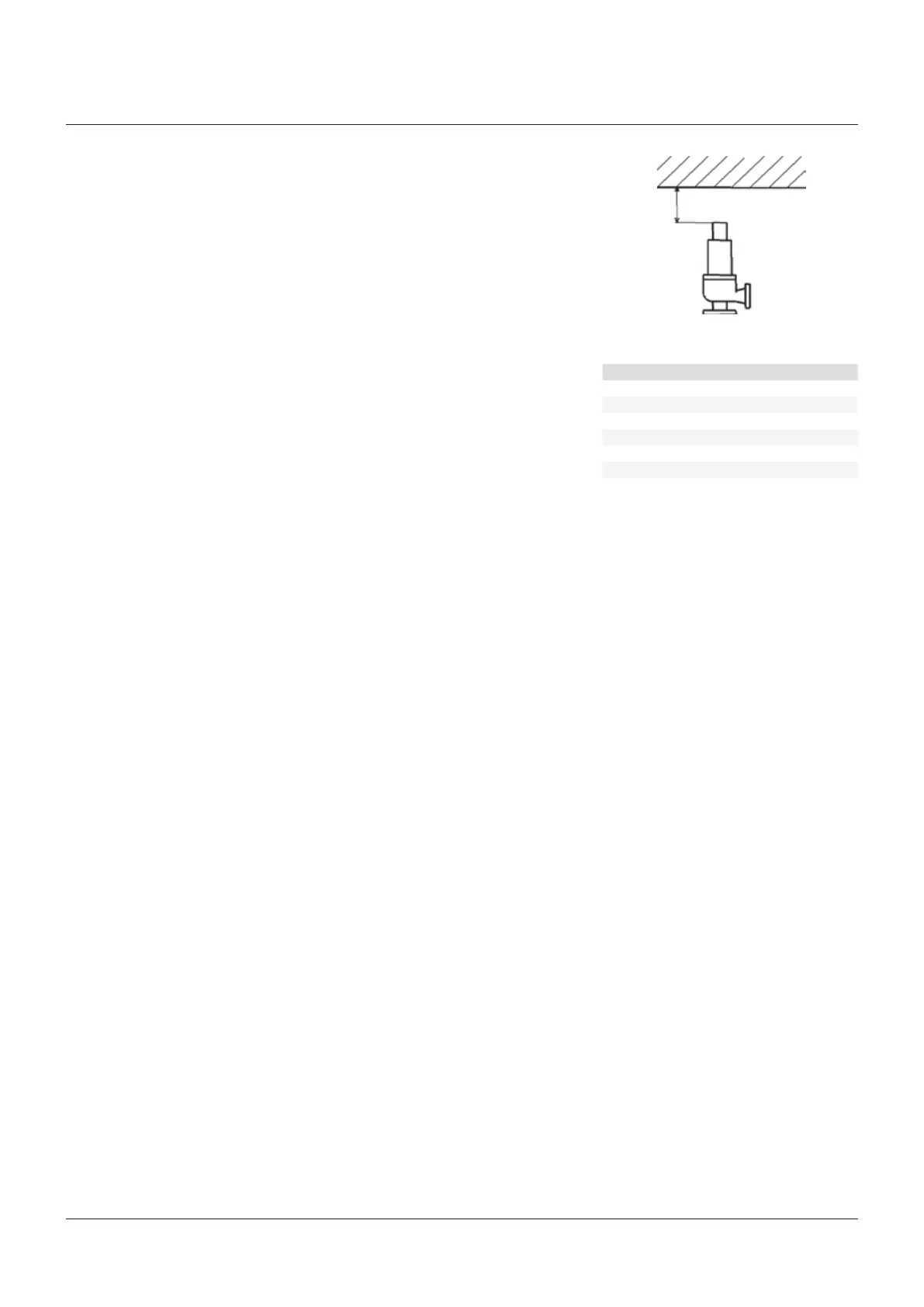

3.3.1 Installation

The installation zone must be easily accessible

for maintenance works. Required free space

above the safety valve see section Dimensions

In case of large safety valves provide for

additional space for lifting gears, at least

500mm.

Position of installation vertical, inlet from

below. Do not brace valve body when fastening;

if necessary compensate bearing of the

supporting brackets.

Lay line in such a way that neither static or

dynamic forces nor forces caused by thermal

expansion may be transferred to the valve body.

PLEASE NOTE

Stresses at the valve body may lead to leaking at

the valve seat!

3.3.2 Inlet line

If possible arrange safety valve directly at the

nozzle of the tank to be protected. Otherwise

lay inlet line between tapping point and safety

valve as short and as poor in resistance as

possible.

In no case the inlet line diameter must be

smaller than the inlet nominal size at the

safetyvalve.

The pressure loss in the inlet line must not

exceed 3% of the set pressure at the greatest

possible discharge quantity.

Check inlet line in regard of pressure vibrations

according to FBR 153 as far as possible.

DIMENSIONS

SKB

Overhead dimension X

A - G

300 mm

EA - JA

12"

H - R

700 mm

KA - RA

26"

S - Z

900 mm

TA

36"

3.3.3 Exhaust line

In no case the exhaust line diameter must be

smaller than the outlet nominal size at the

safety valve.

Back pressures in the exhaust line are

admissible up to 15% of the set pressure and

for safety valves with compensating piston

(SN 144) up to 50% of the set pressure, in

case there are no other restrictions, e. g. with

respect to the strength of the body connection

flange.

ATTENTION

Higher back pressures may lead to an unstable,

uncontrollable behaviour of the safety valve;

chattering or vibrating may destroy the valve seat,

the safety valve or the line and thus lead to failure

of the safety function or to shutdown of the plant!

At the deepest point the exhaust line must be

equipped with a drain which is large enough

to enable the discharge of minor leaks, e. g.

in case of untight valve seat. Particularly in

the open air exhaust line, valve body and drain

must be protected against icing and freezing,

e. g. by (electrical) trace heating; merely

insulating is not sufficient!

Do not exchange the drain connection G ¼” at

the valve body for the lock screw (44) at orifice

letters A40 and B40. Removing the lock screw

(44) may change the function of the safety valve!

ATTENTION

An icy, frozen or clogged exhaust line leads to the

failure of the safety function! Danger of explosion

in case of excess-pressure!

CAUTION

In case of several safety valves with one common

exhaust line, take special safety precautions for

disassembling of only one safety valve to exclude

danger in case of unintended discharge of other

safety valves!

Recommendation! Sound isolate exhaust line

and/or provide the same with silencer; in doing

so, regard allowable back pressure!

ATTENTION

A pressure loss higher than the closing pressure

difference may lead to an unstable, uncontrollable

behaviour of the safety valve; chattering or

vibrating may destroy the valve seat, the safety

valve or the line and thus lead to failure of the

safety function or to the shutdown of the plant!

For discharge of condensate in case of gases

and vapours, the inlet line must have a slope to

the tapping point of 15 degrees at least.

ATTENTION

Condensate at the inlet of the safety valve

changes the functional behaviour and may lead

to an inadmissible pressure increase. Danger of

explosion!

In case of liquids with temperatures higher than

the ambient temperature, the inlet line must

be assembled with slope to the safety valve, or

designed as a siphon-type bend in front of the

safety valve. Thereby, a heat transmission to

the safety valve is avoided which could impair

the tightness at the valve seat.

Loading...

Loading...