5

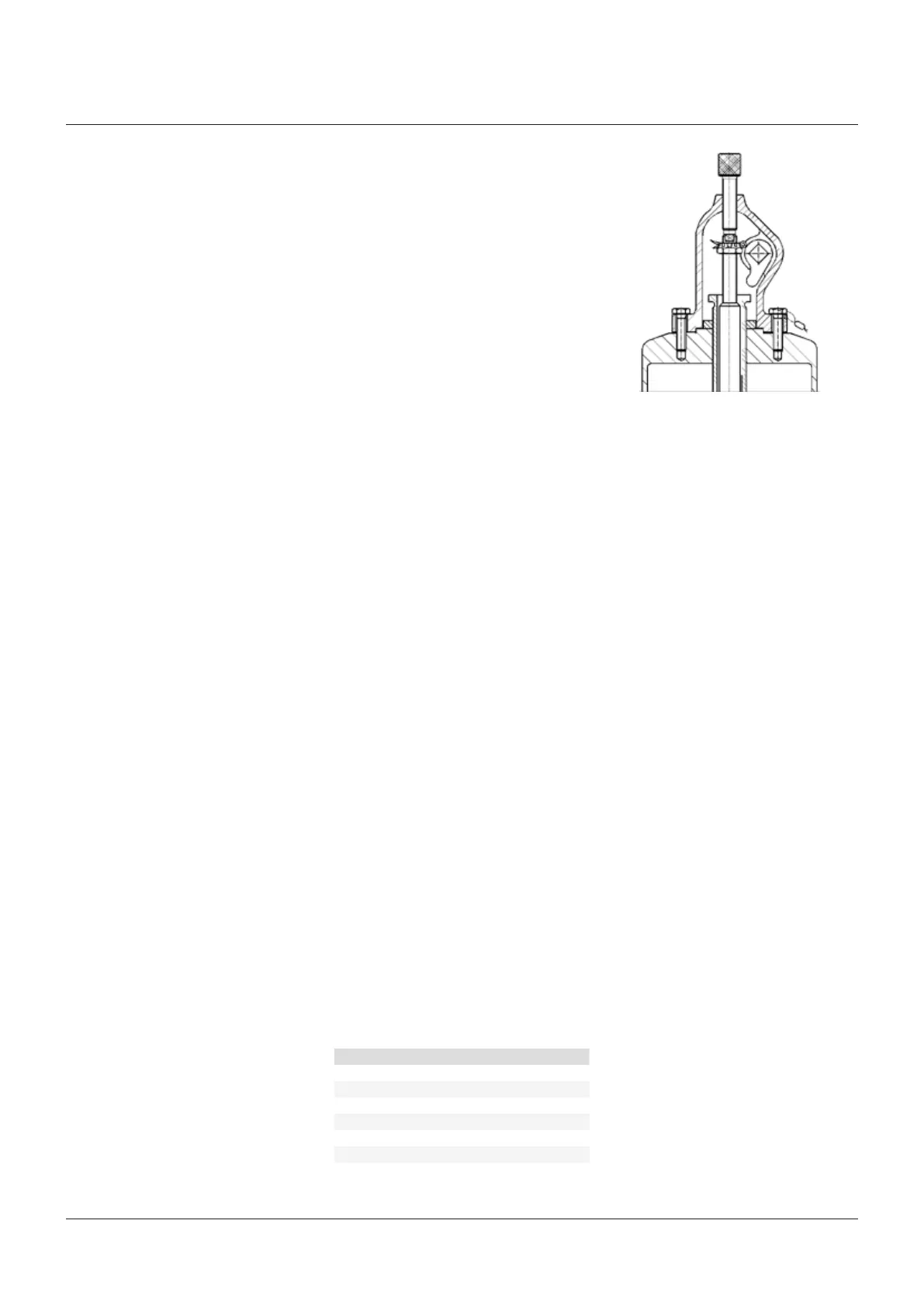

SEMPELL SERIES VSE/VSR FULL LIFT AND NORMAL SAFETY RELIEF VALVE

OPERATING INSTRUCTIONS

3.4 Pressure test

The response of the safety valve must be

prevented.

Either flange off the safety valve and close

the supply line with a blind flange or block

the valve. In case of welded-in safety valve a

pressure test insert can be used.

ATTENTION

In case of a blocked safety valve the test pressure

can amount up to 1.5 fold of the set pressure

without consultation with Sempell.

Turn in the blocking screw instead of the gag

plug (17) and tighten it securely by hand so that

the disc (4) is blocked in closed position. In case

of design with supplementary loading (SN 111)

screw off electric solenoid including cooling

spacer and replace it against a cap (13) with

blocking screw SN 100.

ATTENTION

After the pressure test, restore and check the

ready-to-operate state!

3.5 Commissioning

ATTENTION

At safety valves with weight load, Series VSE 4,

remove blocking screw before commissioning and

assemble gag plug (17) with gasket (40).

The safety valve is delivered ready to operate.

The set pressure is adjusted at works and

secured against unauthorized adjustments by

lead seal. Higher medium temperatures can

lower the set point at approx. 1% per 100°C

and ask for a readjustment under operating

conditions. Standard values see table in section

“Adjustment of the set pressure”.

3.6 Operational test

Function and reliability of the safety valves are

proved by the type test. Therefore operational

tests are generally not carried out in the plant.

This is only usual for steam boiler safety valves.

3.7 Discharge test

• Apply ear plugs.

• Slowly increase operating pressure in the

plant until the safety valve has fully opened.

• Lower operating pressure until the safety

valve closes.

In case of several discharge tests with hot

steam allow intermediate cooling down of the

safety valve as caused by heating of the spring a

slight decrease of the set pressure is possible.

ATTENTION

When discharging, some leaking medium may

escape at the open bonnet (8) in case of safety

valves Series VSE 1 / VSR 1. Danger of scalding by

hot steam!

3.3.4 Insulating

In case of hot medium insulate inlet line and

valve body. In case of gases and vapours

insulate inlet line and valve body very carefully

to avoid condensation.

ATTENTION

Condensate at the inlet of the safety valve

changes the functional behaviour and may lead

to an inadmissible pressure increase; danger of

explosion!

The spring bonnet and a possibly mounted

cooling spacer shall not be insulated as with

heated spring the set pressure decreases.

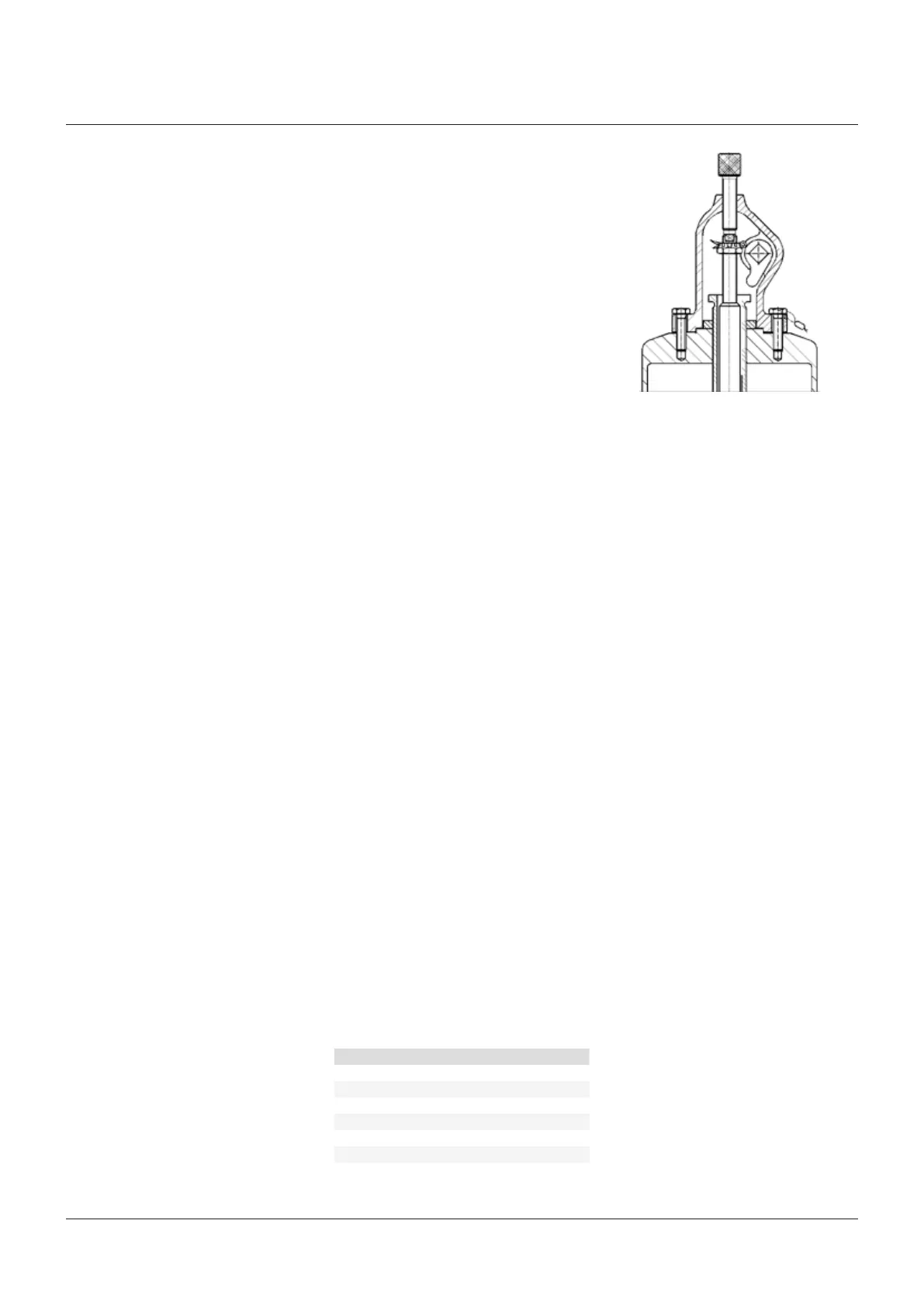

3.8 Adjustment of the set pressure

ATTENTION

A change of the lead sealed spring adjustment

must only take place in the presence of the

competent inspector.

The adjustment of the set pressure takes place

on the test stand. If the set pressure is adjusted

in the plant, the pneumatic measuring device

A 143 should be applied as by means of this

device the set pressure can be adjusted without

increasing the operating pressure.

ATTENTION

Adjusting only with lowered pressure. At operating

pressure working on the tightening screw (11)

may lead to unintended response of the safety

valve. When discharging, some leaking medium

may escape at the spindle guide of the tightening

screw (11). Danger of scalding by hot steam!

Precision of the set pressure adjustment: ± 3%

Remove lead seal. Unscrew cap (13). Loosen

lock nut (28). For working at the tightening

screw (11) secure spindle (7) e. g. with a pin

against rotation as otherwise the valve seat

may be damaged.

Tighten tightening screw (11) (turn right):

setpressure higher

loosen tightening screw (11) (turn left):

setpressure lower

After the adjustment secure tightening screw

(11) with lock nut (28). Mount cap (13) and

leadseal.

Standard values for the change of the set

pressure in % for a quarter turn of the

tightening screw(11):

Orifice letter SKB Changes in %

AIV EAIV 10

AI-III, B, C EAI-III, FA 7

D-H GA-KA 4

J-M LA-NA 3

N-R PA-RA 1.5

S-W TA 1

X-Z 0.5

Loading...

Loading...