Foreign Objects: Coins, hairpins, or

other metal objects which have fallen

inside the set.

Connecting an External Speaker:

Wiring accessories to a set that do not

have an isolation transformer.

The list could go on and on. The key

thing is that there is a shock hazard any

time a piece of metal comes in contact

with a hot chassis.

The PR57 Leakage Test: It’s Fast and

Simple

The PR57 simplifies the safety leakage

test, because all circuits are internally

referenced to the isolated output of the

PR57. First, the PR57 allows the leakage

test to be made while the unit under test

is still connected to the isolated output.

Other procedures require a direct

connection to the AC line. The test should

be done with the set plugged into the

PR57. This reduces the chance of getting

a shock while performing the test and

also means that you do not have to

remember to move the AC line cord to a

non-isolated outlet.

The PR57 leakage test does not require

earth ground reference because all of the

current paths are referenced back to the

secondary of the isolation transformer.

This allows you to make the test

anywhere, including in a home that is not

wired with grounded outlets.

To perform the Leakage Test with the

PR57:

1. Plug the PR57 into a properly

grounded three wire AC outlet.

2. Push the AC VOLTS OUTPUT

pushbutton and adjust the VOLTS

control for a reading of 117 volts on

the PR57 meter. This establishes a

117 volt reference for uniform test

results.

3. Press the HI SIDE leakage button

and plug the Safety Leakage Probe

into the PROBE jack on the front

panel of the PR57.

4. Touch the probe tip to every user-

accessible piece of exposed metal,

including screw heads, antennas,

antenna terminals, knobs, all control

shafts with knobs removed, handles

or anything that even appears to be

metallic.

5. Read the leakage on the µA

LEAKAGE meter scale of the PR57.

To read the true leakage current,

push the button on the probe while

probing the test point.

6. Push the LO SIDE LEAKAGE push-

button and repeat the leakage test to

the same points tested in step 4.

The Safety Leakage Probe has a switch

which places a current-limiting resistor in

series with the test circuit. The resistor is

bypassed when the button on the probe

is depressed.

The resistor limits the amount of current

to prevent the meter from pegging when a

test point with high leakage is contacted.

This condition occurs when the point

being tested is connected directly to

either side of the AC line.

Any test point that reads close to full

scale (800 µA) with the button in the “out”

position is connected directly to one side

of the AC line. If, for example, the meter

reads full scale when the LO SIDE button

is depressed, there is a direct connection

to the common side of the AC line. This is

the side of the polarized line cord plug

with the larger connector.

Leakage readings which are less than full

scale indicate that there is a leakage path

(but not a dead short) to the point being

tested. Simply press the button on the

Safety Leakage Probe to read the actual

leakage current present.

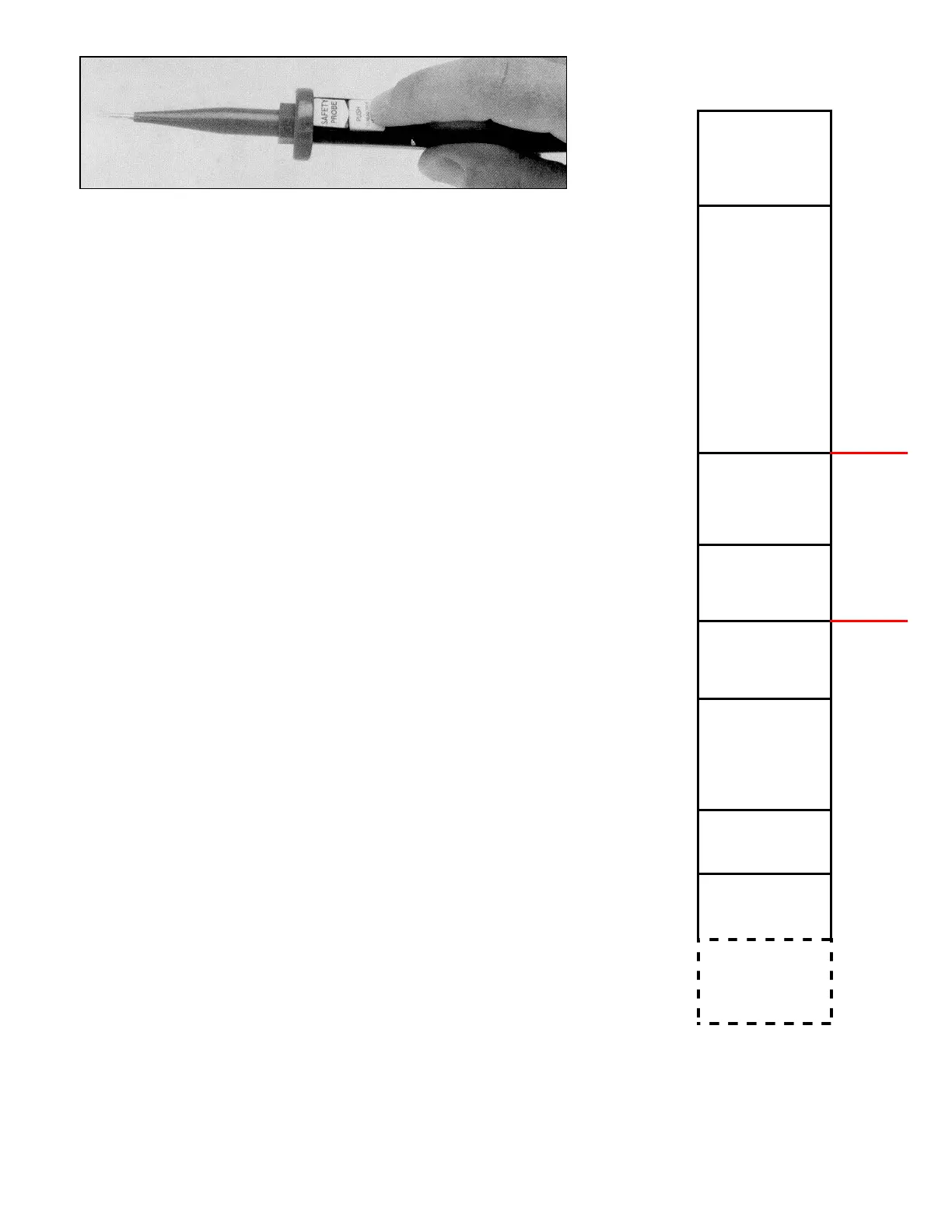

Severe burns, not

fatal unless vital

organs burned.

Heart stops during

shock, may restart if

current is removed

before death occurs.

Heart Fibrillation,

in 1.4 seconds;

usually fatal.

Breathing stops;

often fatal.

Highest

Danger

Zone

Cannot let go.

Current may increase

to fatal level.

Painful sensation.

Mild sensation.

Imperceivable

10A..

9…

8…

7…

6…

5…

4…

3…

2…

1A…

900mA..

800……

700……

600……

500……

400……

300……

200……

100mA…

90……

80……

70……

60……

50……

40……

30……

20……

10mA

9…

8…

7…

6…

5…

4…

3…

2…

1mA

900µA

800….

700….

600….

500

400

300

200

100µA

UL Limit for

consumer

products

UL Limit for

Hospital

Equipment not

connected

directly to body.

Fig. 3: The pushbutton of the Safety Leakage Probe is depressed when

the actual value of leakage current is to be read on the PR57’s meter.

Fig. 4: The effects of electrical

shock on a human being.

Loading...

Loading...