must be checked. If necessary, change the direction of rotation by

exchanging the connection of two phases.

Before closing the terminal box it is essential to check that:

• The connection is done according to the connection diagram

• All terminal box connections, mounting parts and grounding connections are firmly tightened

• Auxiliary devices are functional

• All minimum values of the clearance distances between bare, voltage-carrying parts towards

the ground and to each other (10mm bus 750V) are complied with

• Unused cable entry openings and the condensate drain (if present) are sealed dust-tight and

water-tight.

When commissioning, it is advisable to observe the current consumption under load in order to

recognize any possible overload or asymmetries on the line.

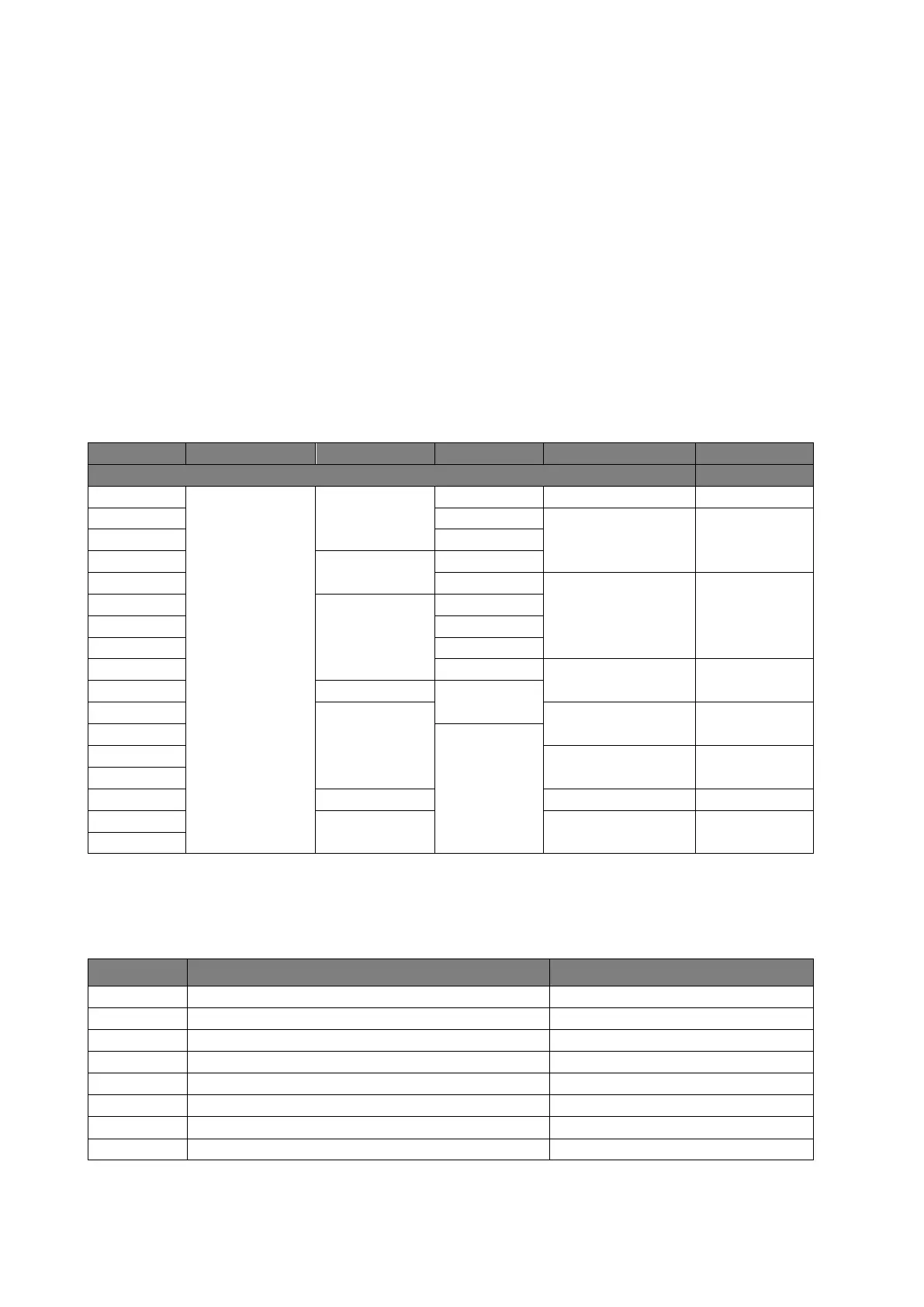

6.2. Tightening torques

Table 3 shows tightening torques for screws of the end shields, bearing caps and terminal box.

Thread / Tightening torque (Nm)

Table 3. Tightening torques for terminal box, end shield and bearing cap.

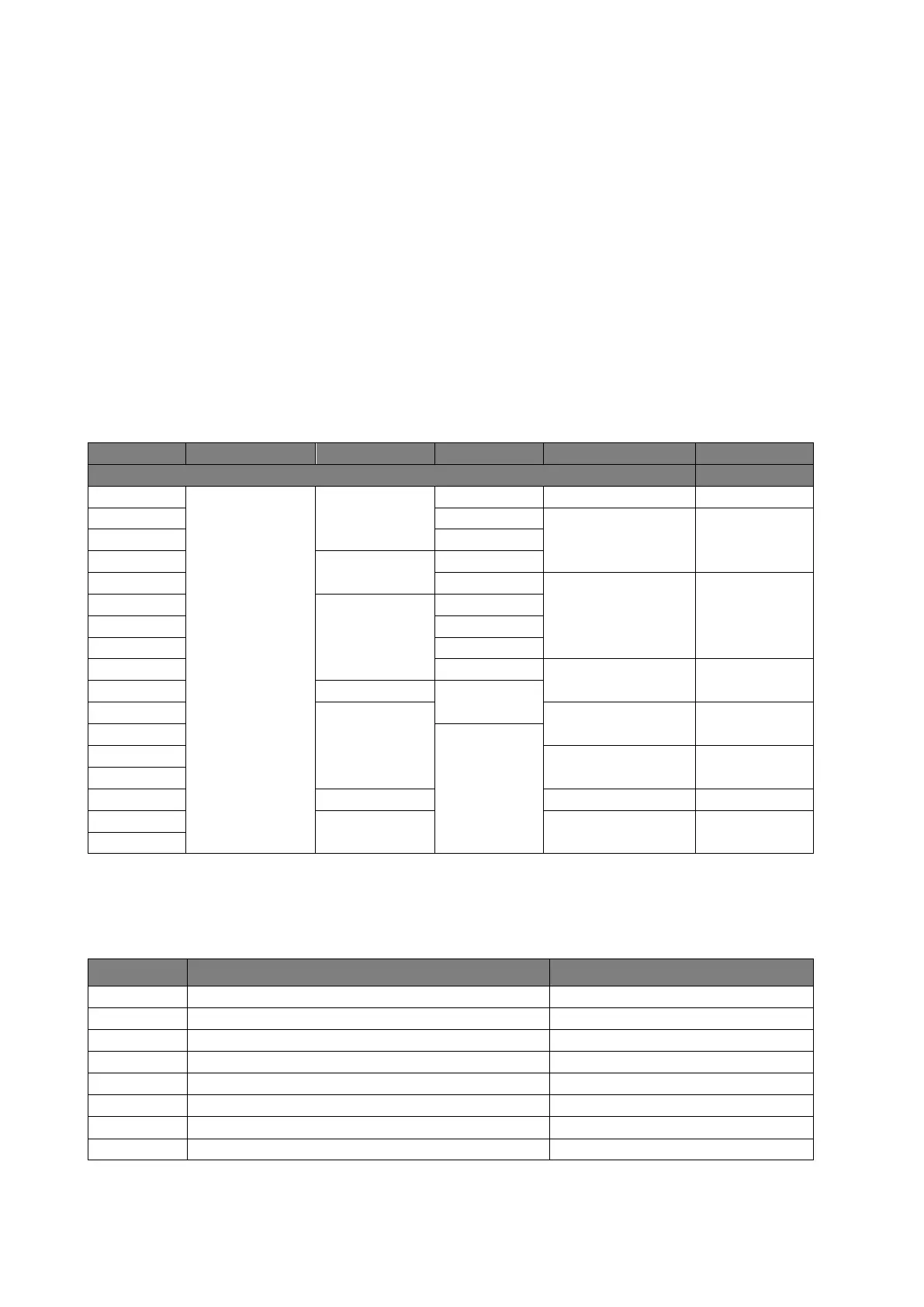

If a motor has an arrangement on feet (type B3, B34, B35), the following tightening torques for the

screws on the motor feet must be complied with:

Tightening torque (Nm) Min.

Tightening torque (Nm) Max.

SEVA-tec GmbH - Lether Gerwerbestrasse 10 - 26197 Ahlhorn - www.seva-tec.de

8

Table 4. Tightening torques for motor feet screws.

Loading...

Loading...