instructions covering the valve, positioner and any

accessories. Where the valve is operated by electric,

hydraulic or electro hydraulic actuation, follow the IOM

instructions provided by the actuator manufacturer.

Only persons qualified through training and or experience

should install, operate and maintain this product. In case of

questions about these instructions or the valves please

contact the nearest Severn Glocon office before proceeding.

Instructions in the following paragraphs describe the

installation procedures for the actuator. Instructions not

included are to be performed in accordance with standard

industry acceptable practises as may be required by local

codes, specifications and or regulations. Users should refer

to BS 6683 “Guide to installation and use of valves”.

Storage

Unless specifically specified by the contract, the actuator (or

valve and actuator) are packed for indoor storage at job site.

For short term storage the actuator or valve and actuator,

should be installed in a fire resistant weather tight and well

ventilated building. The equipment should be kept at a

temperature of –20F (-29deg.C) to +120F (48deg.C). The

area should be constructed and situated so that it will not be

subjected to flooding; the floor should be similarly level, firm,

protected and well drained. Actuators and valves should be

on pallets or shoring to permit air circulation.

For longer storage, a corrosion preventative should be

considered that is compatible with the process fluids.

Further advice should be sought from Severn Glocon.

Handling

Applicable codes regulations and industry practices must be

followed when handling or lifting valves. Care should be

exercised to protect instrumentation / ancillary equipment.

Severn Glocon lifting guidelines are available on request.

Installation

Make sure adequate overhead clearance exists when

installing the actuator. Minimum clearance is 150mm. It is

usual to use the actuator with a suitable valve positioner. If

this is the case, the air supply and instrument signal

connections must be connected as per the positioner

manufacturer’s instructions.

WARNING: Do not exceed the recommended air supply

pressure shown on the Severn Glocon specification sheet,

as injury to personnel or damage to equipment may occur.

The use of an air filter regulator on the air supply line is

recommended. Instrument quality air is required for

operation of the actuator and any ancillaries fitted.

The weight of the actuator valve assembly should be taken

into consideration when mounting on to a valve. Supports

may be required depending on the actuator orientation.

Actuator Removal and Fitting to Valve

Two types of fitting arrangement for actuators are possible.

Smaller actuators may be fitted by a half ring yoke design

method with either lock nut or stem clamp between stem

and actuator piston. Alternatively, all sizes of actuators may

be fitted by a bolted yoke and stem clamp design method.

IMPORTANT: See warnings on page 1 in regard to isolation

of items to be worked on and carry out safe isolation before

beginning work.

WARNING: Escaping air can cause personal injury, avoid

skin contact and wear eye protection. Take care to correctly

support any parts being lifted. Take care to remove any

linkage mechanisms before starting work to avoid damage.

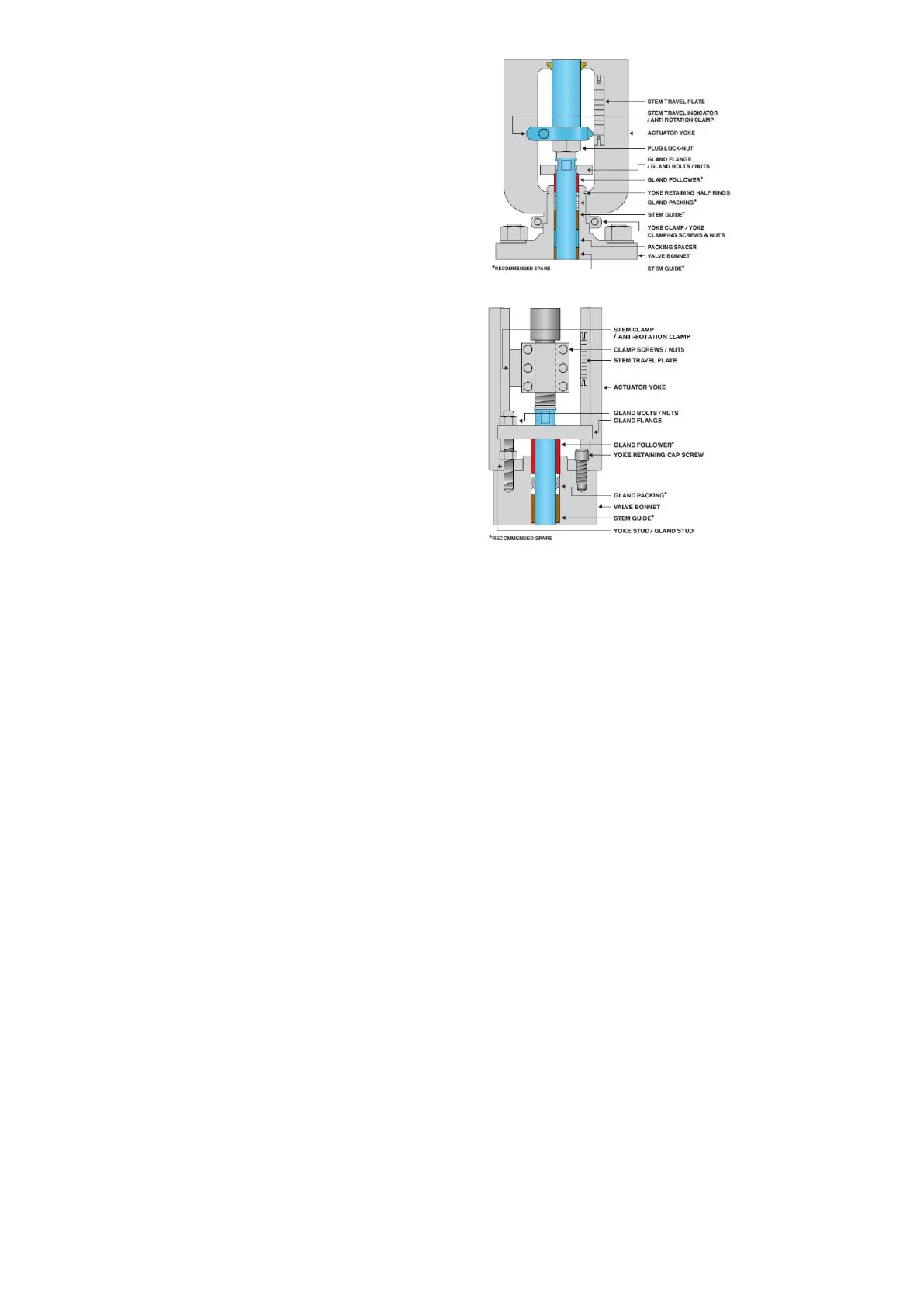

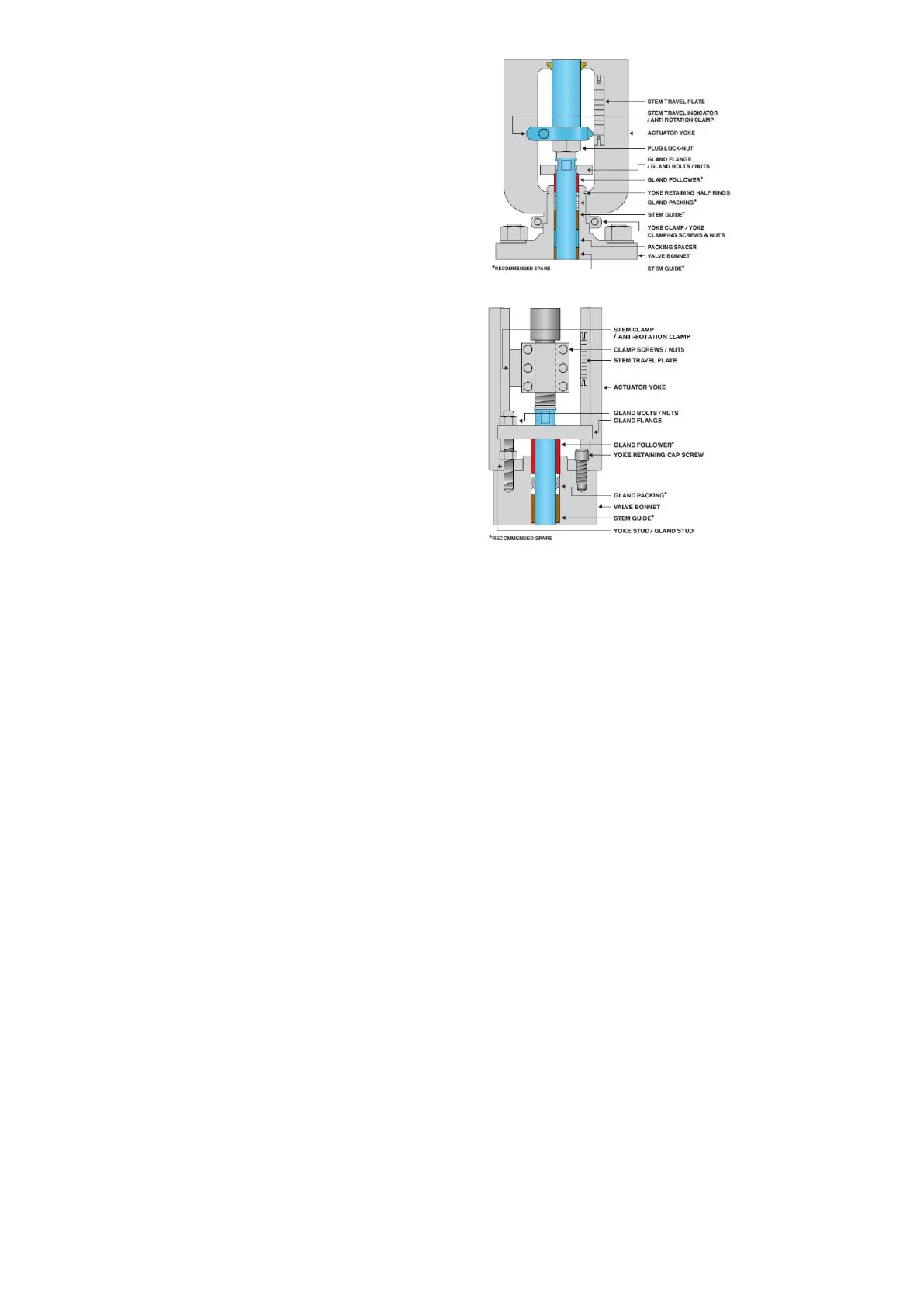

Half Ring Yoke Design showing lock nut connection

(Actuator sizes

P25, 50 and 100)

Note: This design

may be fitted with

a stem clamp

instead of the lock

nut design. In this

case read relevant

sections of both

design options for

fitting

Bolted Yoke showing Stem Clamp Design

(All Actuator Sizes)

NOTE Yoke Fixings

and Gland Flange

Studs shown 90

degrees out of position

for clarity on Bolted

clamp design

Actuator Removal (Half ring fixing method).

Connect suitable slings to support the actuator weight. For

air fail actuators the valve plug/actuator stem should be

moved to approx. 50% open by means of air. This can be

achieved by using a temporary air line with a manually

controlled pressure regulator and connected to the lower air

port (spring close model) or the upper air port (spring open

model) in the actuator. With the valve in this position, the

plug locknut can be loosened, remove the yoke clamps and

spin the actuator off the valve plug. Caution; Do not allow

plug to rotate during unscrewing. When the actuator

disconnects from the plug, the plug may drop onto the seat

position; take care not to trap fingers. If the plug does not

drop, push the plug to the closed position. Remove the plug

lock nut, and gland flange. Push the actuator downwards

towards the valve body to allow removal of the two yoke

retaining half rings from the groove in the top of the valve

bonnet. The actuator can now be lifted clear of the valve

and all air vented from the actuator. Caution: This will cause

the actuator piston rod to move to the air fail position.

Actuator Fitting (setting the correct plug position)

Before fitting the actuator, extend the piston rod to the

maximum extended position and mark location on the yoke.

Connect suitable slings to support the actuator weight for

both air fail actions. For air fail close type lower the actuator

on to the valve body; during this operation loosely fit the

gland flange and plug lock nut. By rotating the actuator onto

the plug stem it will then be possible to fit the yoke retaining

half rings. Once these have been fitted rotate the actuator in

an anticlockwise direction until the half rings are a snug fit in

the yoke. The yoke clamps, the gland bolts and nuts can

now be fitted. Caution; During this process ensure the plug

is not driven hard into its seat or is allowed to rotate.

For air fail open type actuators use a temporary air line and

manual regulator as above to move the actuator down

slowly so as to be able to rotate the actuator onto the plug

stem. See prior caution notes. Relieve all air pressure and

disconnect. By screwing the actuator onto the plug it will be

possible to allow the yoke to be pushed down towards the

valve body and the yoke retaining half rings can be fitted.

Allow the actuator to rise after fitting to hold these rings in

place then fit the yoke clamps, gland bolts and nuts.

Loading...

Loading...