Setting the plug to its seating position.

With Actuator Piston Rod fully extended, (this can be seen

by the marks made earlier on the yoke) and with the plug

set fully on the seat, the actuator piston should extend to a

position short of the mark by approximately 1.5 - 3mm.

Adjust the plug to achieve this position by screwing the

actuator in or out. Do not rotate the plug. Move the actuator

up and down slowly to ensure smooth operation. Set the

plug lock nut. This position may need to be adjusted again

later depending upon the type of positioner when fitted.

Fully stroke the actuator to ensure smooth operation. NOTE:

When installing new or re-fitting the actuator, refer to valve

IOM detail on appropriate tightening of packing gland.

Actuator Removal (Bolted Stem Clamp fixing method)

Set the actuator just off its valve seat by use of a temporary

air line/regulator as above. Undo the clamp screws and nuts

to separate the actuator piston from the plug stem (the

piston may move up/down and in rare cases contact the

plug stem). The plug position may have to adjusted slightly

so as to allow the split clamp to release from its thread.

Air in the actuator can now be slowly released. Loosen the

gland bolts and gland flange. Loosen the yoke retaining cap

screws by approximately. 6mm to ensure spring force is fully

relaxed (actuator rocks easily). The actuator can now be

removed taking care not to damage the valve plug.

Actuator Fitting (setting the correct plug position to ensure

proper seating force is applied during normal operation.)

Fitting follows the reverse methodology of removal, but plug

should be set to its on seat position. Operate the actuator

piston down to its fully extended position (it should not hit

the top of the plug stem). Do not rotate the plug. The piston

should then be raised by approximately 6mm before fitting

the clamp. Adjust the stem position to ensure the threads

mesh fully and fit the other half of the clamp tightly. Fully

stroke the actuator to ensure smooth operation.

Pre-Operation

The actuator and control valve positioner must be set to

correctly close and seat the valve so as to not give rise to

premature trim degradation. If a manual handwheel override

is provided in the actuation system, ensure this is in the

disengaged or neutral position. Clean the actuator shaft of

any foreign matter. Always use correct tools including the

use of torque wrenches to assure bolts are not over

tightened during any checks carried out.

Operation

In operation, ensure that the actuator operates smoothly

and that there is no juddering or unusual motion. If the

actuator exhibits any strange behaviour, please contact your

nearest Severn Glocon representative immediately.

IMPORTANT: For all valve adjustments refer to relative IOM

instructions. If any doubts exist, contact SEVERN GLOCON

Maintenance

Actuator parts are subject to normal wear and tear and must

be inspected and replaced as necessary. Inspection and

maintenance frequency depends upon the severity and

importance of the service.

WARNING: The actuator may be spring loaded. Use care to

follow normal safety procedures when removing actuator

casings and end caps. When turning off the air supply the

actuator will move to its fail-safe position. Keep personnel

away from the moving parts of the valve and actuator during

this process to avoid personnel injury. The actuator may

move very quickly during this process.

Spare Parts

Whenever an actuator is disassembled, it is recommended

that all soft parts are replaced. These are consumable parts.

Troubleshooting

Jerking or sticky stem travel

AUXILIARY HANDWHEELS AND LIMIT STOPS

Top-mounted, Continuously Connected Handwheels

Fitted on

Actuators

Size P25,

50 and 100

Advanced Maintenance

The top-mounted, continuously connected hand-wheel is

totally, enclosed, so only checking for general condition is

required. However, disassembly may be necessary if the

mechanism fails. When reassembling the handwheel, be

sure to clean and lubricate the screw and drive nut with a

multi-purpose grease and replace ‘O’ rings with new.

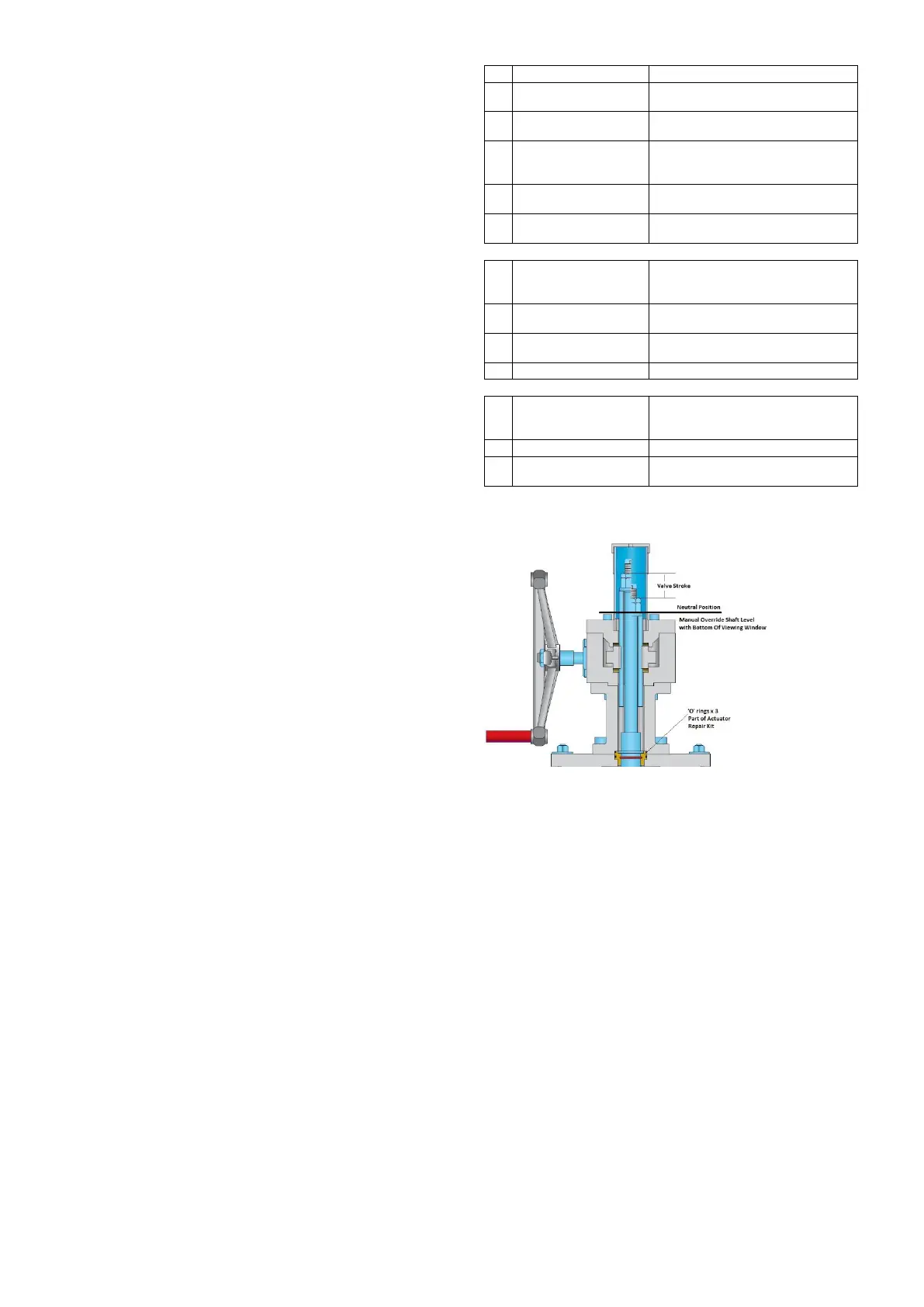

IMPORTANT: After operation of the override it must be

returned to the neutral position for automatic operation

(shown by manual override shaft level with the bottom of the

viewing window in the hand-wheel end cover tube (6).

Operation

If a pneumatic failure occurs, or if manual control of the

valve is desired, the unit can be operated as follows:

1. Set the three-way bypass valve (located on the

pneumatic supply line to the positioner) to “Hand” to vent the

air pressure from the actuator. NOTE: a three-way valve is

installed in the supply line only when there is no lock-up

system or volume tank. On volume tank or lock-in place

systems, the bypass valve is located between the top and

bottom cylinder ports. However, on some pneumatic circuits

the single three-way bypass valve may be substituted by

two two-way manual valves. Consult the pneumatic circuit

supplied with the actuator documentation.

WARNING: By venting the air, the actuator will move to the

fail safe position, this may be fast. Please keep away from

moving parts including the positioner linkage to avoid injury.

Loading...

Loading...