2. To open the valve, turn the hand-wheel counter-clockwise

to retract the plug. To close the valve, turn the hand-wheel

clockwise to extend the plug.

4. To return the valve to automatic control, return the hand-

wheel nut to the ‘neutral’ as shown by the handwheel

position indicator and set the three-way bypass valve (see

previous NOTE) to ‘auto’. The neutral position is indicated

when the top of the screw aligns with the marked line on the

cap liner (see diagram).

5. Adjusting the hand-wheel nut to a position other than

neutral provides a limit open or close stop function

Declutchable Handwheels

Size P100,

and 200

Pin and

lever in auto

position

(Lever Up)

Advanced Maintenance

This is an enclosed unit. For long life, it is important to keep

a coating of multi-purpose grease on the acme threads and

engaging collets at all times. A grease point is provided and

a multi-purpose grease should be pumped into the unit

periodically. Oil can be applied to the hinge pins, the

operating lever and the bearings on handle mechanism.

WARNING: If the mechanism has been operated incorrectly

it is possible to strip the acme threads on the actuator piston

rod and replacement parts will be required.

Operation

If an air failure occurs, or if manual control of the valve is

desired, the handwheel override can be operated as follows:

1. Turn off the pneumatic supply. This is carried out by

operating the three-way bypass valve (located on the air

supply line to the positioner) to “Hand” to vent the air

pressure from the actuator. NOTE: three-way valves are

installed in the supply line only when there is no lock-up

system or volume tank. On volume tank or lock-in place

systems, the bypass valve(s) is located between the top and

bottom cylinder ports. However, on some pneumatic circuits

the single three-way bypass valve may be substituted by

two two-way manual valves. Consult the pneumatic circuit

supplied with the actuator documentation.

WARNING: Venting air will move actuator to the fail safe

position, this may be fast & personnel must keep away from

moving parts including the positioner linkage to avoid injury.

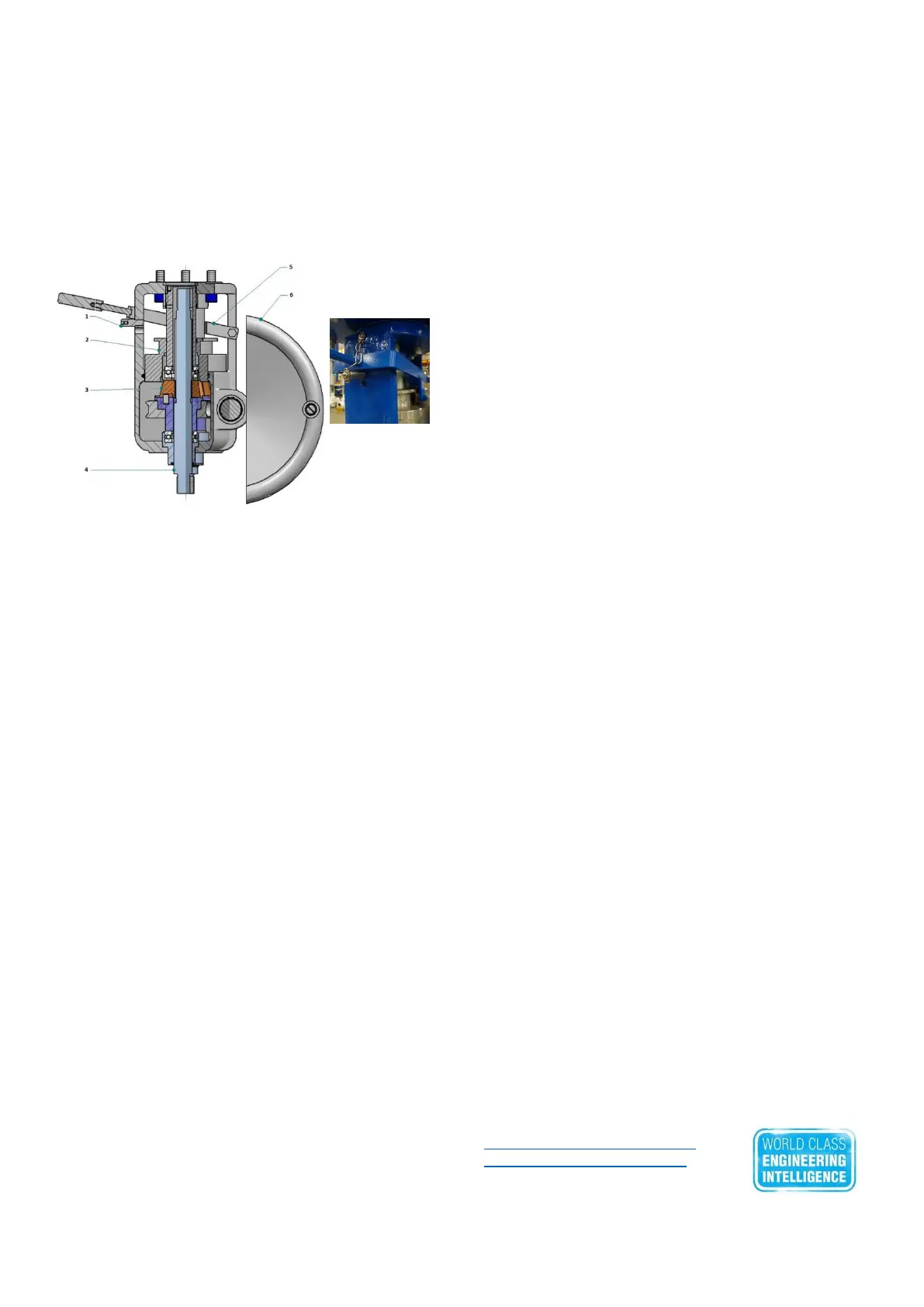

2. After isolating the pneumatic supply remove the operating

lever locking pin (1), from its hole beneath the operating

lever assembly (5). Do not lose this pin (it is normally held to

the body of the unit by a chain). It is now possible to move

the operating lever (5) down towards the valve body. This in

turn moves the internal engaging piston (2) and pushes the

split segments of a spring loaded operating nut (3), which

will engage onto the connecting rod (4) with its acme thread.

It may be required to rotate the hand-wheel (6) at the same

time to ease this process. Once the operating handle has

moved and the operating nut fully engaged on the acme

thread the locking pin (1) is used to hold the operating lever

in position by inserting into the lower of the two holes.

3. With the hand-wheel unit now fully engaged on the

actuator piston rod thread, rotating the hand-wheel

clockwise will close the valve and by rotating the hand-

wheel counter-clockwise, the valve will open.

4. To return to automatic control, using the hand-wheel

mechanism, firstly position the valve fully to the air fail

position.

WARNING: Control valves must only ever be put back into

automatic control mode once user has confirmed the valve

is fully in its Fail Safe mode position. Failure to do so can

cause damage to equipment and severe injury to personnel.

5. Pull out the operating lever locking pin (1) from its

locating hole above the operating lever assembly (5). To

declutch the hand-wheel assembly move the operating lever

(5) up away from the valve body. This moves the engaging

piston (2) away from the operating nut and allows operating

nut (3) springs to disengage operating nut from connecting

rod (4). It may be necessary to rotate the hand-wheel (6)

slightly to allow the acme threads to disengage. Confirm

disengagement by checking the handwheel moves freely.

WARNING: At this point, just in case there is still a load on

the actuating stem from the valve, meaning the actuator

piston rod will move to the no load position, it is advised to

keep personnel away from any moving parts.

6. When the acme thread is fully disengaged the operating

lever will be in its fully up position and the locking pin (1) is

used to hold the lever assembly in position by inserting this

locking pin in the upper of the two holes.

7. To return to automatic control, turn on pneumatic supply

by operating the three-way bypass valve (see previous

NOTE) to ‘auto’. This reconnects the air supply to the

positioner.

Disclaimer: Neither Severn Glocon Ltd, or any of its

affiliated entities assumes responsibility for the selection,

use or maintenance of any product. Responsibility for proper

selection, use, and maintenance of any product remains

solely with the purchaser and the end user. The contents of

this publication are presented for information purposes only,

and while every effort has been made to ensure their

accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or

services described herein on their use or applicability. We

reserve the right to modify or improve the designs or

specifications of such products at any time without notice.

HEAD OFFICE: SEVERN GLOCON LTD,

Olympus Park, Quedgeley, Gloucester, GL2 4NF. UK.

Tel +44(0) 845 2232040

SEVERN GLOCON INDIA PVT LTD,

F96/97, SIPCOT Industrial Park, Irungattukkottai, Chennai,

602 05, INDIA, Tel +91(0)44 47104200

AFTERSALES & SERVICE: SEVERN UNIVAL LTD,

Heywoods Industrial Park, Birds Royd Lane, Brighouse, W

Yorkshire, HD6 1NA, UK. Tel +44(0) 845 6070710

Aftersales@severnglocon.co.uk

EPSsales@severnunival.co.uk

www.severnglocon.com

Severn Glocon Manual Ref: SGG-IOM-ACT-M01-REV03

Date 27-02-2017

Loading...

Loading...