3. When the machine is working, please do not touch the electrode. After

processing, please make the high frequency output“+、-”pole touch each

other to make short circuit discharge, which could prevent electric

shock.

4. Avoid being used in heat-treatment shop, electroplating workshop and

the field with corrosive materials or a large amount of dust. Please pay

attention to keep the machine away from water and protect the circuit

from being damaged by corrosive substance. Store pro

perly after use to

protect it from foreign object.

Prohibit working in hazardous environments, such as the fire ban area.

5. When the spindle is close to the upper limit or lower limit, please turn

off the servo switch or turn back the spindle to avoid the spindle

stopping at the limit position for a long time.

6. The machine is equipped with precision electronic components, avoid

bumping it when moving. Before using, do some shock prevention,

keep away from stamping equipment or planer which could cause

vibration and shock. Cut off the main power after use, clean up and

keep it properly.

7. The electric conductivity of work piece and the electrode clamping have

great influences on the processing efficiency. Before processing, Clean

up the rust or oxide film of the work piece to get better conductivity.

Clip the alligator clip in a proper position to keep the electrode and

alligator clip nearby, and meanwhile keep the work-piece from

damaging by electric current.

8. After a period of using, the spindle should be lubricated to ensure the

good condition of the work head.

9. To avoid accidents, non professionals please

do not attempt

to open the

power box for servicing.

VI. Selection of Electrode Materials and Work Liquid

Easy processing and electrical erosion resistance materials are usually

used as tool electrodes, such as copper, graphite and copper-tungsten alloy,

etc. Generally, the economic brass which works well is priority being used in

removing broken taps, etc.

The working liquid is dielectric medium, which plays the role of

cooling and chip removal. So the dielectric medium with low viscosity, high

flash point and stable performance are usually being used, such as pure water,

kerosene, liquid to prevent oxidation of aluminum. For iron or steel parts,

clean tap water could achieve good effect.etc. When processing aluminum

parts, kerosene could be used as the working liquid.

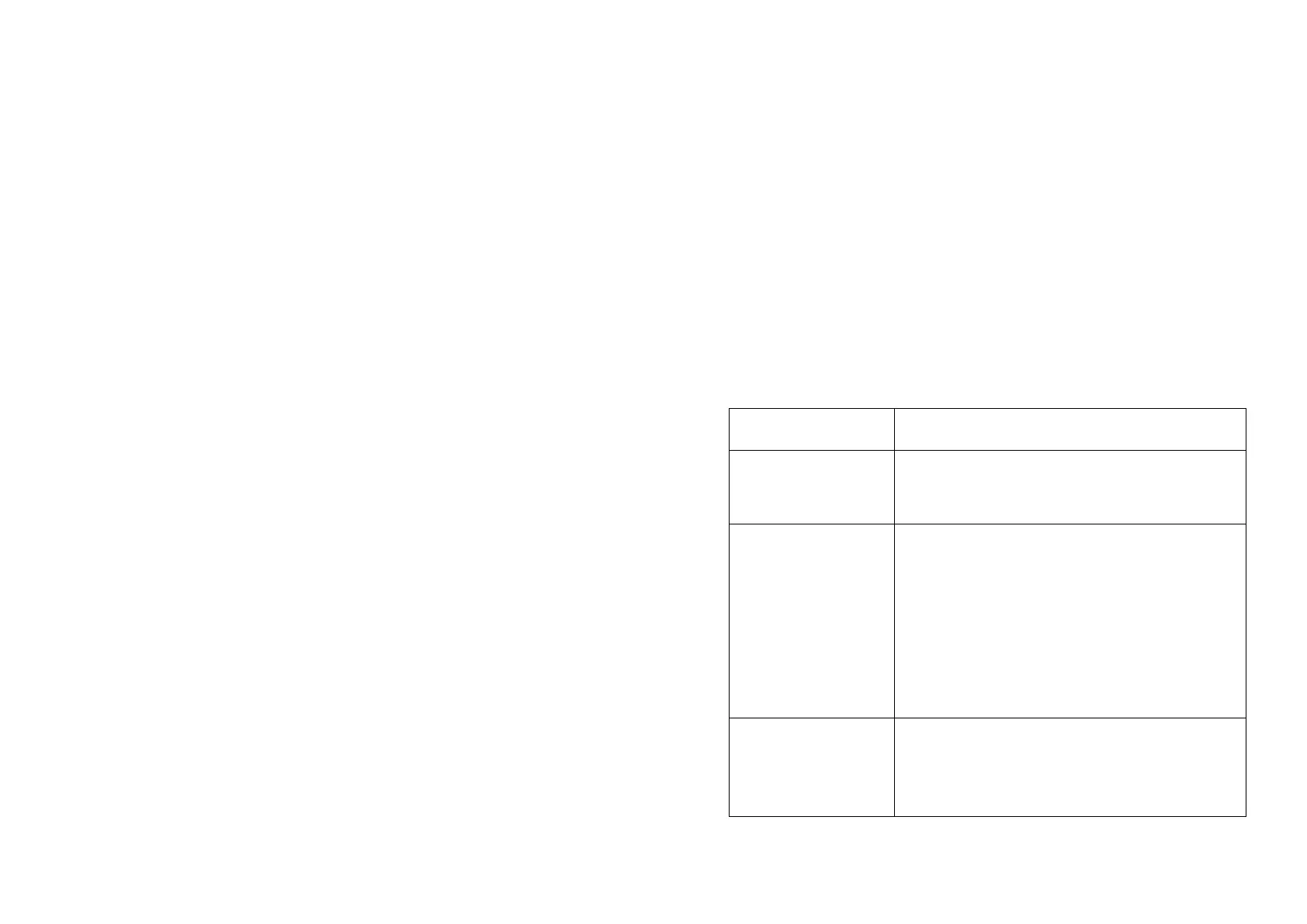

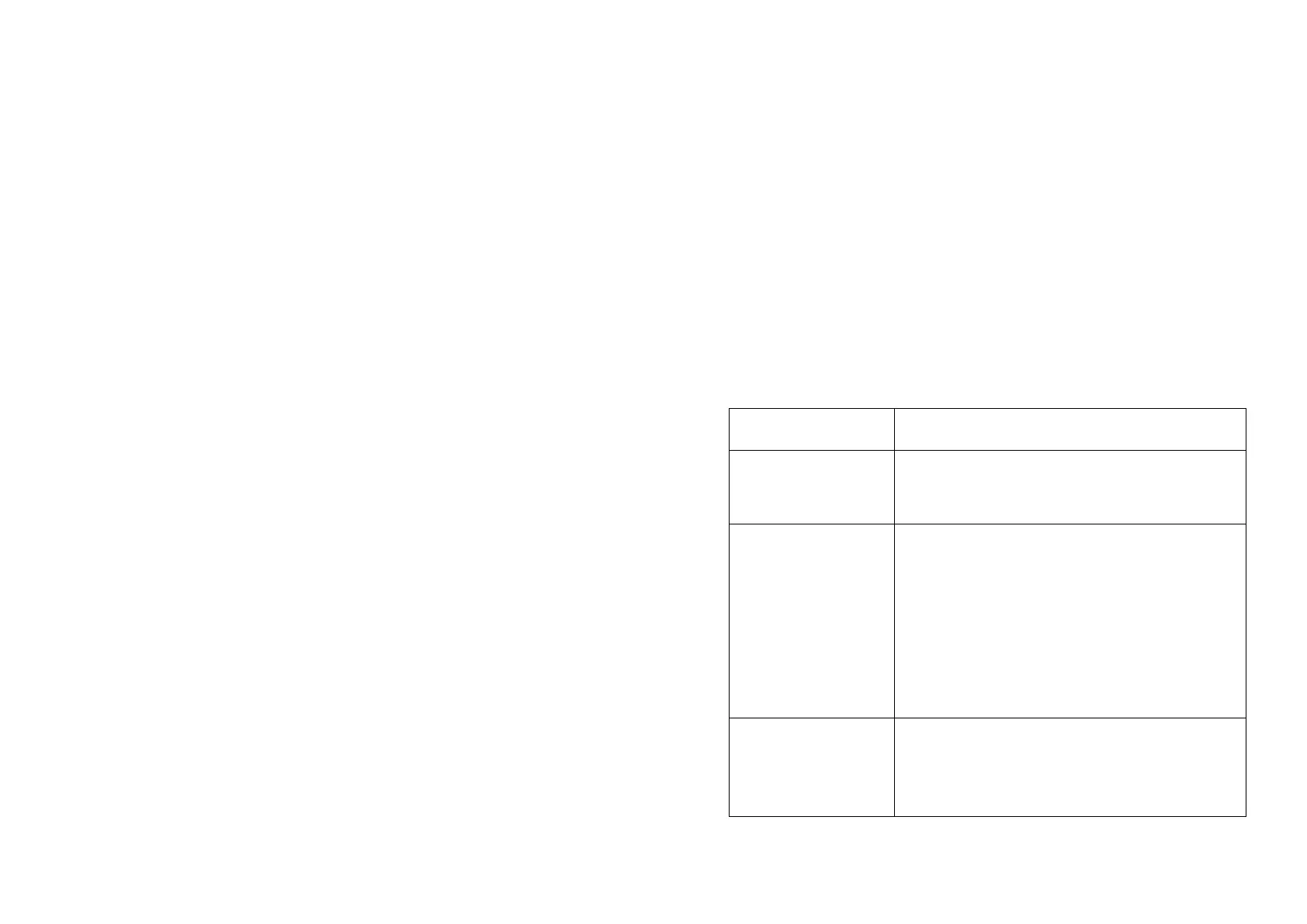

VII. Failures and Solutions

Failure Reasons and Solutions

1.The power supply is not connected. Please make

sure the power cord is securely connected

2.Fuse Burn, replace the fuse

After turning on the

machine, the spindle

cannot move.

1.The power cord is not connected. Please connect

the power line again.

2.The spindle reach the upper limit and start the

travel switch. Open the machine and press the reset

button for 2-3 seconds to get the machine back to

work.

3.Something is wrong with the servo controller.

Please contact us immediately.

1.Check the liquid level of the water supply source

to ensure that the water pump is under the liquid

surface

2.Open the pump to clean the rotor timely.

9 10

Loading...

Loading...