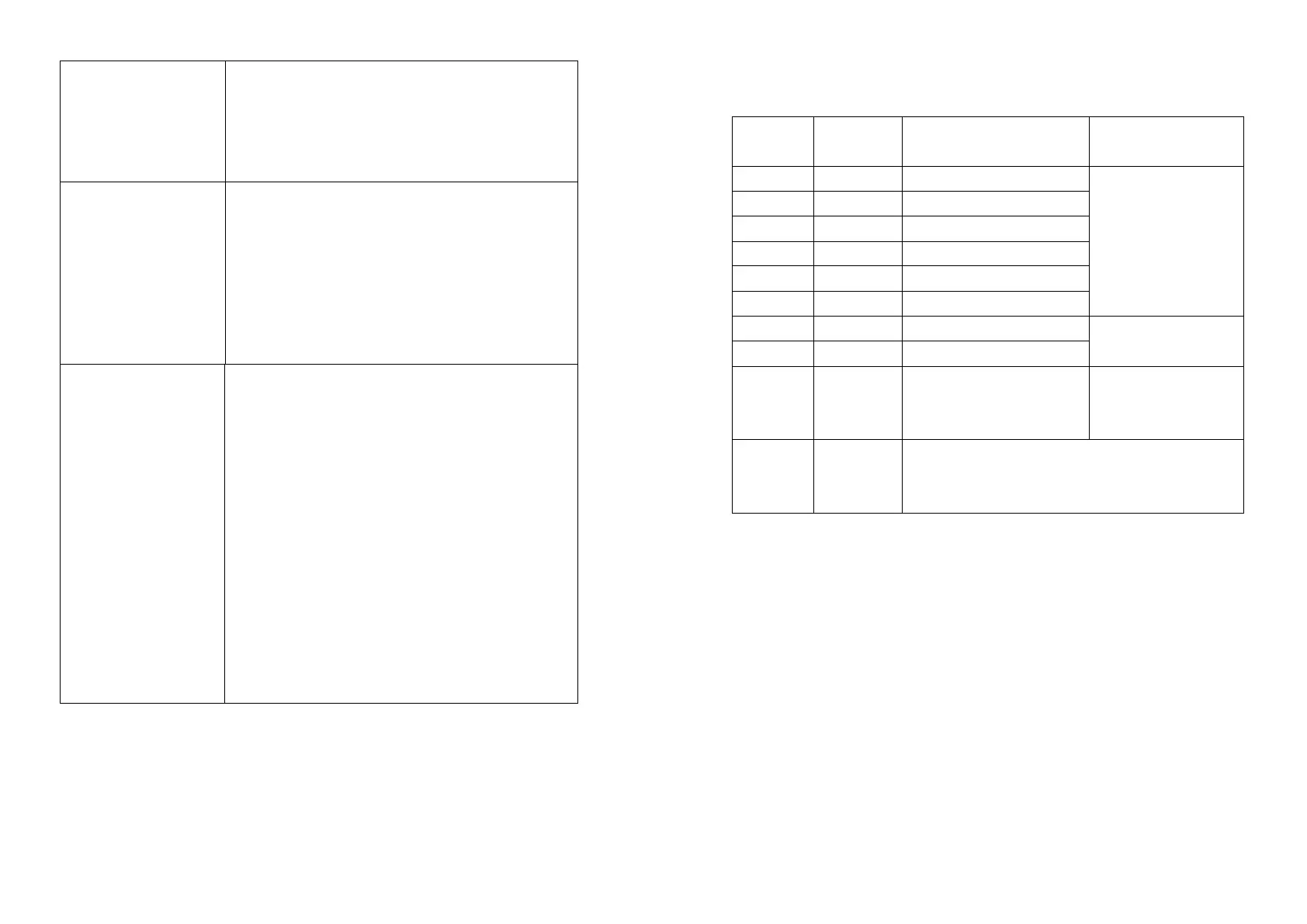

When the electrode

touch the work piece.

There is no electric

spark.

1.The high frequency cord are not connected or not

connected well. Connect/ Reconnect the high

frequency cord.

2.Something wrong with the high frequency cord.

Contact us immediately.

The processing speed

is good but the hole is

not very deep, and the

electrode consumption

is very large.

1.The polarity of the high frequency is reverse.

Adjust the polarity of the high frequency cord.

2.The machining parameter is unsuitable.

Adjust

the machining parameter.

3.The diameter of the electrode is too small while

the electric current is very large.

Adjust the current

switch and the servo knob to reduce the

current.

The processing is

unstable, pointer of

the ammeter swing

back and forth with a

large amplitude.

1.The servo knob is not at the best position. Adjust

the servo knob.

2.The work piece or electrode are not clipped well.

Replace the work piece stably and clamp the

electrode tightly.

3.The water is not flowing at the best position. And

the water is not enough. Adjust the position of

water pipe.

4.The processing comes into a certain depth. The

amplitude of swing is large which cause the current

unstable. Lift up the work head and reprocess.

Adjust the position of work piece. Change the

electrode and make sure the vertical machining.

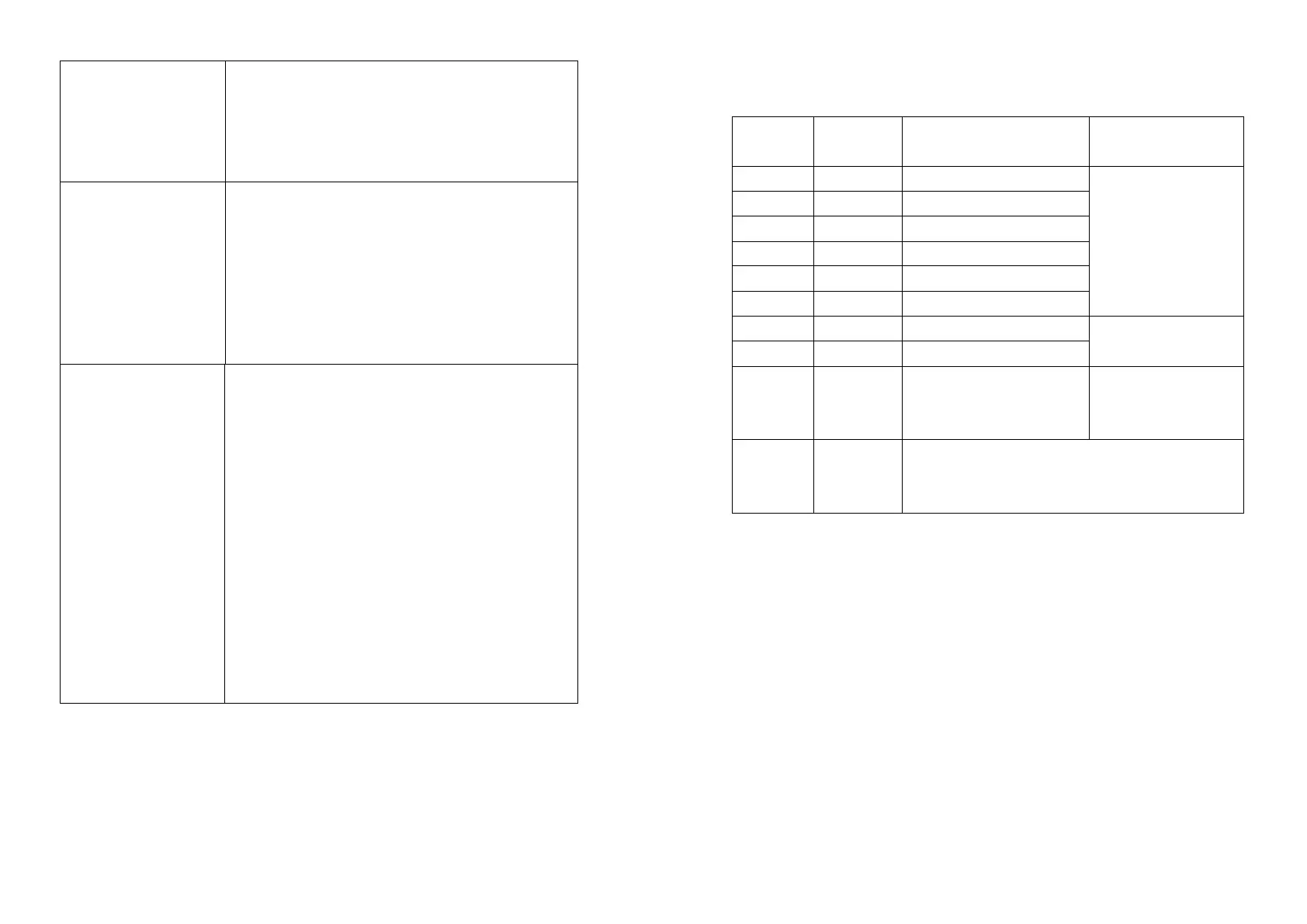

VIII. Selection of Electrode Size

Selection of electrodes for removing general broken objects could refer

following table:

Electrodes

Recommended(mm)

For the electrodes,

the shorter, the

better.

(there will be less

jitter with short

electrode)

Taps above M20 can

be processed by

several times.

Method Recommended: drill a straight,

triangular, square or hexagonal groove, and

remove it with matching tools.

VIIII. How to remove broken tap, drill, screw etc. out

The common ground of tap, drill, etc. tools is that the central part is

solid. So the tap or drill could be removed out by smashing the central part.

Before processing, please clean up the rust or oxide layer. When processing

deep hole or work piece in deep channel, hollow electrode and high pressure

water pump could help increasing the pollution discharge speed. (Figure 3)

Tap smaller than M12 can be removed out by smashing the central part.

For the tap that diameter is too big, it can be divided into two parts or

four parts by sheet electrodes. In practical use, after process for a while, you

could use a chisel to knock the debris down and then use a tweezers or

magnet to remove the debris, and restart the processing again. In this way, it

Electrode discharge area is generally about 0.5mm diameter larger than

themselves. For example, an electrode of 3mm diameter could process a hole

of 3.5 diameter. The electrode should be chosen according to the actual

processing conditions to avoid injury to thread and the discharge area should

be considered.

11

12

Loading...

Loading...