can reduce the discharge area, and improve the processing efficiency.

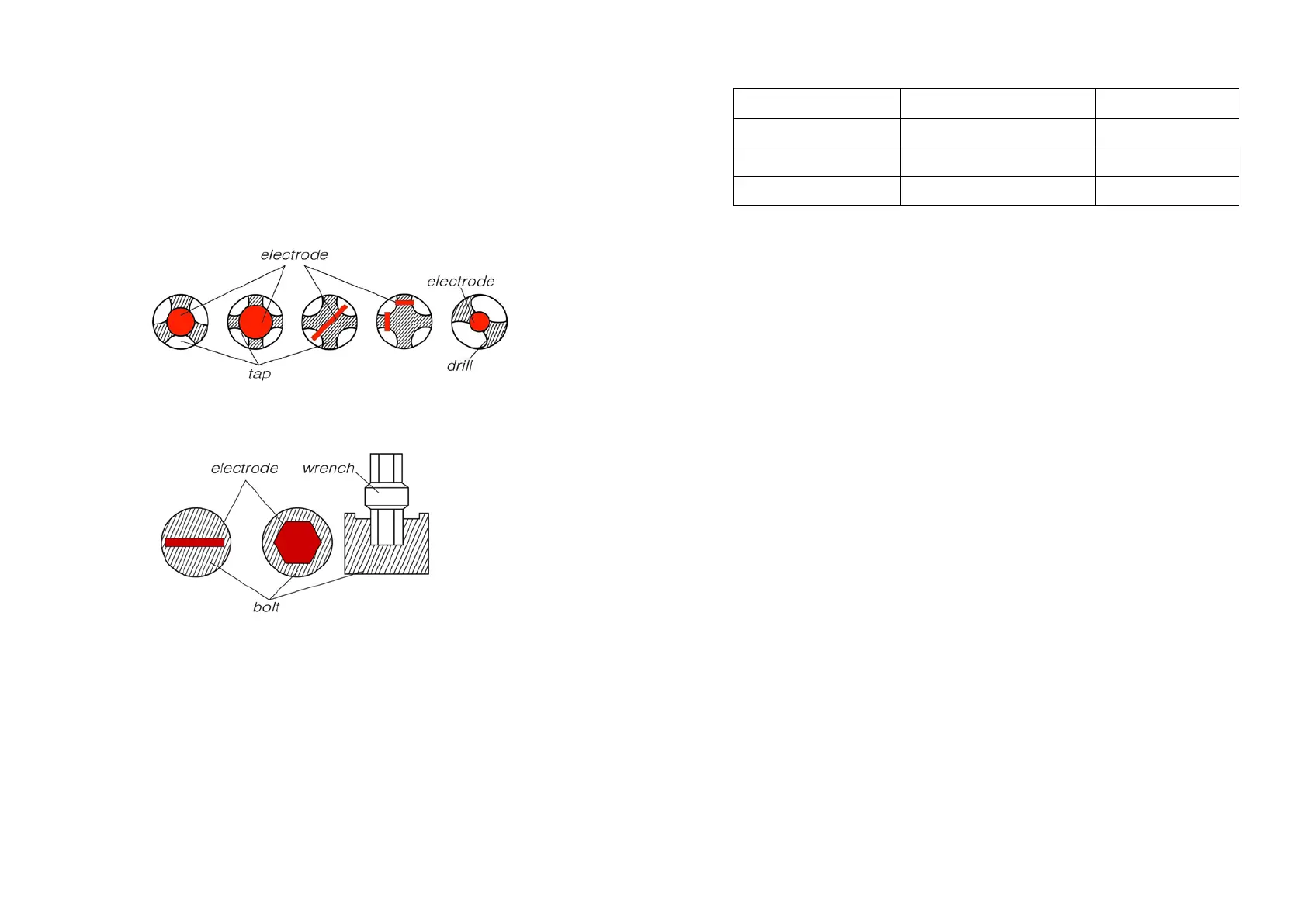

When the diameter of the bolt is too big or its strength grade is over 8.8,

general processing method is unsuitable. You can process a groove of

2-3mm

depth with a sheet electrode. Then unscrew it with a screwdriver or hexagon

wrench. If the processing position is too deep for general screw extractor, the

Allen wrench

would help

.(Figure 4)

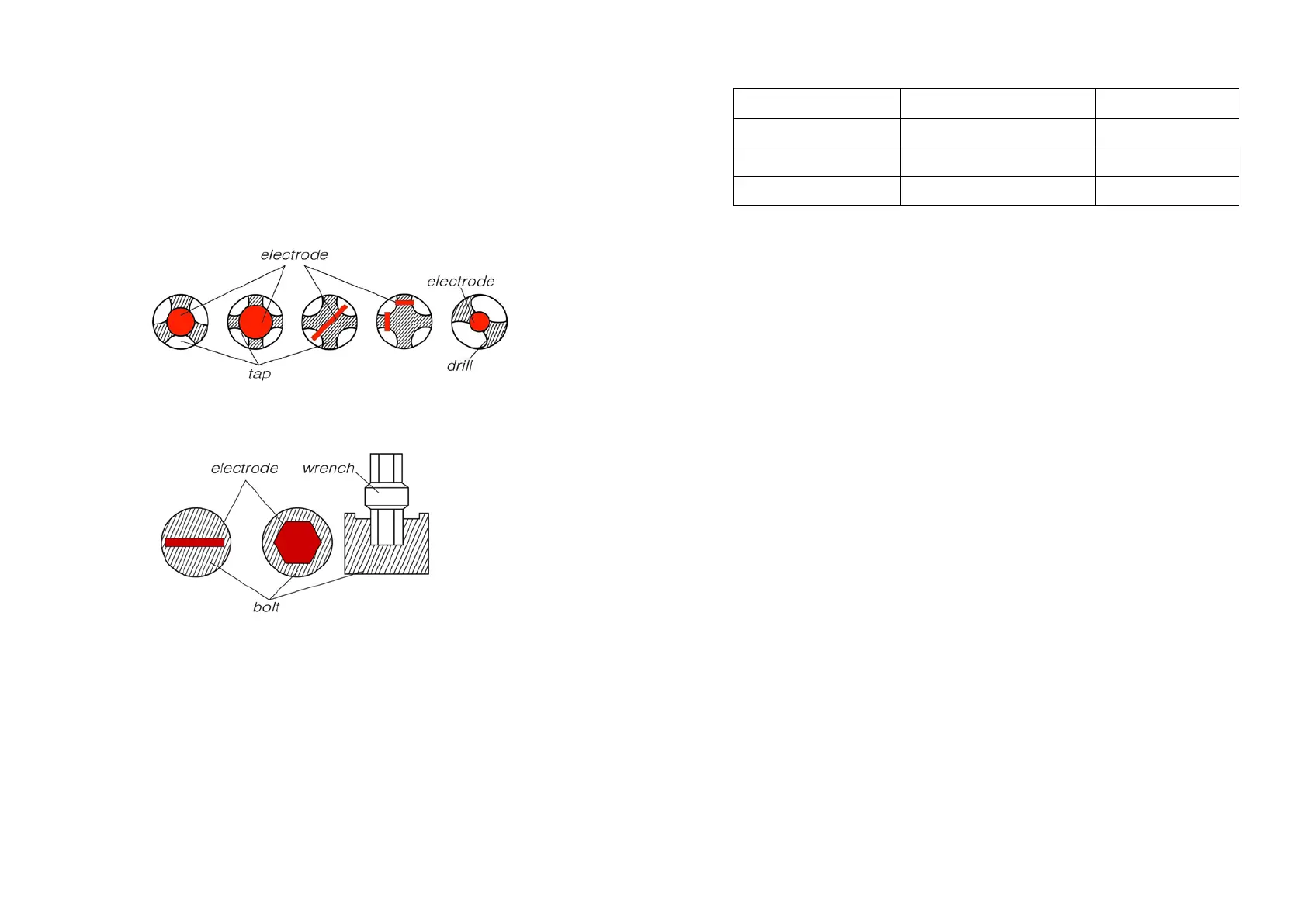

(Figure 3)

(Figure 4)

X .How to adjust current and servo.

The broken tap remover’s current has four grades, what they are: high

frequency switch, stepper switch, stepper current (I) and stepper current (II).

High frequency switch controls the on/off of the pulse current, stepper switch

controls the discharge time(pulse width), stepper (I) and stepper (II) control

the magnitude of current; The more switches you turn on, the bigger current

you have.

Please refer to the table

below:

When adjusting the servo switch, firstly turn servo knob to the right of

the central line, the spindle begins to decline. After the electrode reaches a

certain distance to the work piece and starts to discharge, please slightly

adjust the servo knob to reach a suitable discharge gap(there will be a sound

of clear and continuous electric shock and the ammeter is in a stable state).

Now the current is stable, the machine works efficiently. The control system

will automatically detect this suitable distance and keep this proper discharge

gap to ensure the continuous and stable discharge. When processing is

finished, please turn the servo knob to the left of the central line, the spindle

will rise.

XI. How to clamp the electrode to avoid work piece being damaged

During electric discharge machining, the negative (blue line) should

connect the electrode while the positive (right line) should connect the work

piece. This method could reduce the consumption of tool electrode and

decrease the surface roughness.

Sometimes there is a slight gap between alligator and terminal, the

electric discharge may damage the work piece. To avoid this situation, you

could screw on a threaded hole or insert a pin to the hole nearby, then clamp

it by the alligator. The clamping distance of positive and negative should

maintain the principle of proximity to reduce the current losses in

transmission. Make sure the work piece is well fixed, the alignment between

the central axis and the work piece is very important for the processing

quality.

13 14

Loading...

Loading...