R-677 - 29

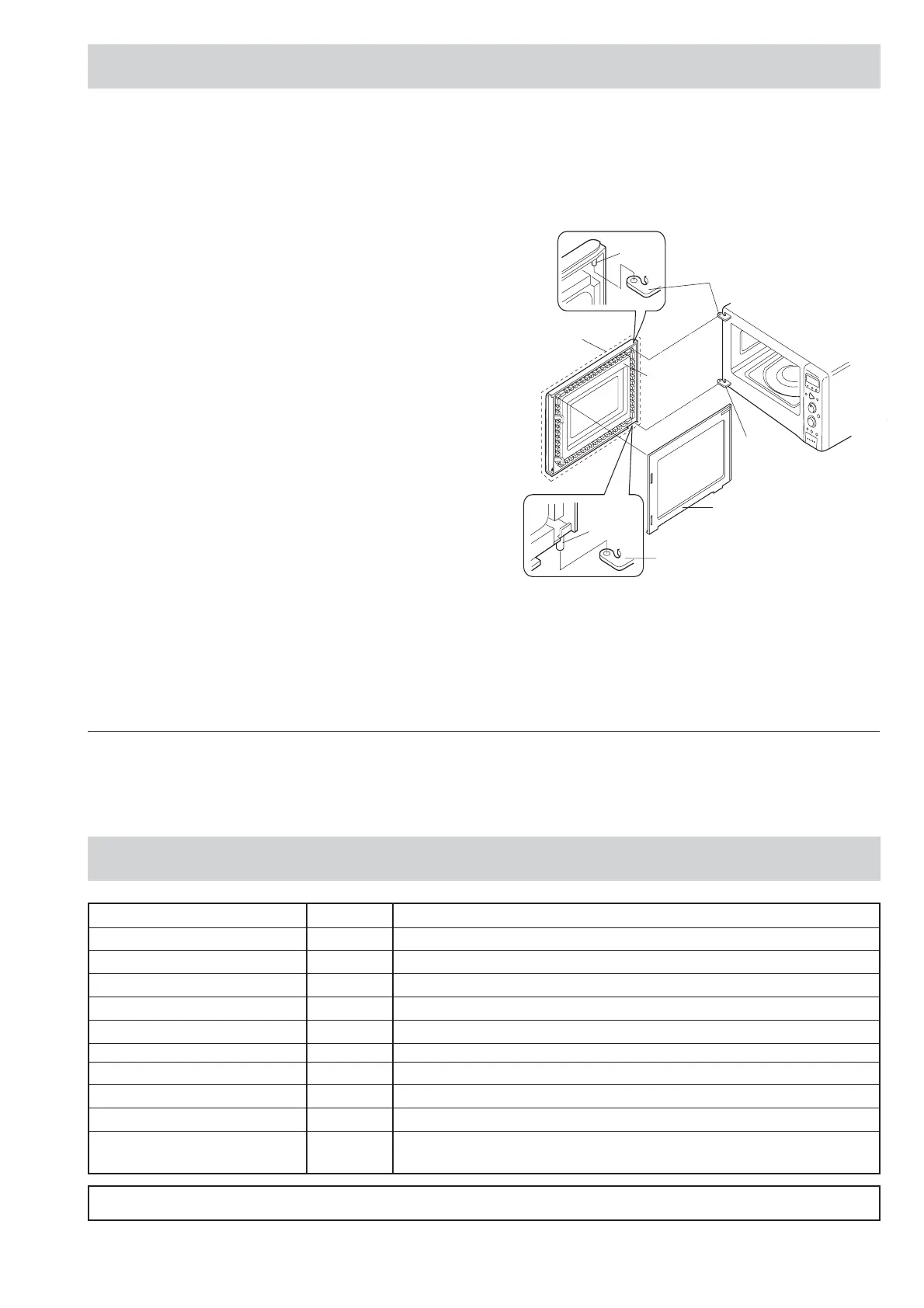

4. Hold the door panel to the door frame with four (4)

screws.

5. Catch two (2) pins of door panel on two (2) hole of upper

and lower oven hinges.

6. Re-install choke cover to door panel by pushing.

Note: After any service to the door;

(A) Make sure that door sensing switch and primary

latch switch are operating properly. (Refer to

chapter "Test Procedures".).

(B) An approved microwave survey meter should be

used to assure compliance with proper micro-

wave radiation emission limitation standards.

(Refer to Microwave Measurement Procedure.)

After any service, make sure of the following :

1. Door latch heads smoothly catch latch hook through

latch holes and that latch head goes through centre of

latch hole.

2. Deviation of door alignment from horizontal line of

cavity face plate is to be less than 1.0mm.

3. Door is positioned with its face pressed toward cavity

face plate.

4. Check for microwave leakage around door with an

approved microwave survey meter. (Refer to Micro-

wave Measurement Procedure.)

Note: The door on a microwave oven is designed to act

as an electronic seal preventing the leakage of

microwave energy from oven cavity during cook

cycle. This function does not require that door be

air-tight, moisture (condensation)-tight or light-

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE CONT...

PIN

PIN

LOWER

OVEN HINGE

UPPER

OVEN HINGE

LOWER

OVEN HINGE

CHOKE COVER

DOOR

PANEL

DOOR SUB

ASSEMBLY

tight. Therefore, occasional appearance of mois-

ture, light or sensing of gentle warm air movement

around oven door is not abnormal and do not of

themselves, indicate a leakage of microwave en-

ergy from oven cavity.

Figure C-8. Door Replacement

TEST DATA AT A GLANCE

PARTS SYMBOL VALUE / DATA

Special fuse F1 20A / 250V

Fuse F2 F 8A

Thermal cut-out (HVT) TC1 145°C Off / 115˚C On

Thermal cut-out (OVEN) TC2 150°C Off / 130˚C On

Grill heating element (top) GH1 Approx. 76 Ω / Insulation resistance > 10 MΩ

Bottom heating element GH2 Approx. 132 Ω / Insulation resistance > 10 MΩ

Oven lamp OL 230–240 V 25W

High voltage capacitor C AC 2100V 1.02µF

Magnetron MG Filament < 1Ω / Filament – chassis ∞ ohm.

Power transformer T Filament winding < 1Ω

Secondary winding Approx. 160 Ω / Primary winding Approx. 2.5 Ω

WARNING: DISCONNECT THE PLUG WHEN MEASURING RESISTANCE.

Loading...

Loading...