14

PRECISION MACHINE TOOLS Ver 2 Maintenance Manual

2-1 Cautions for High Speed Processing

During high-speed processing (S = 8000 rpm or above; F = 300 mm/min or above), the shank and

the style of the cutter has a critical impact on spindle lifespan and processing precision. Matters that

need more attention are:

1). Grasp the cutter before running the spindle to avoid damaging the spindle.

2). During high-speeding chipping (8000rpm or above), use only G2.5 level cutters and shanks that

have been calibrated for dynamic balance. The reason is that vibration generated from centrifugal

force may damage the spindle bearing and rapidly wear out the cutter.

3) Balance tolerance for the shank and the cutter combination is affected by the following three

factors: rotation speed of the cutter, balance tolerance of the spindle, and weight of the shank.

Therefore, using a shorter cutter with a smaller diameter for high-speed chipping is advantageous in

terms of spindle vibration, temperature increase, thermal deformation, and processing precision.

4) The geometric shape of the cutter blade has an effect on cutter abrasion. Increase the angular

backlash of the blade can reduce abrasion due to scratches. Suitable cutter materials can also

minimize abrasion during high-speed processing; for example, cermet, tin or tic coated carbide

cutters have longer lifespan than conventional cutters. Ceramic (Si

3

N

4

) cutters are better than cermet

cutters.

5) Perform another dynamic balance calibration after combining the cutter and the shank together.

The dynamic balance standard should be G2.5 or above.

50 – 6000 rpm Level G6.3

Balance level

6000 – 18000 rpm Level G2.5

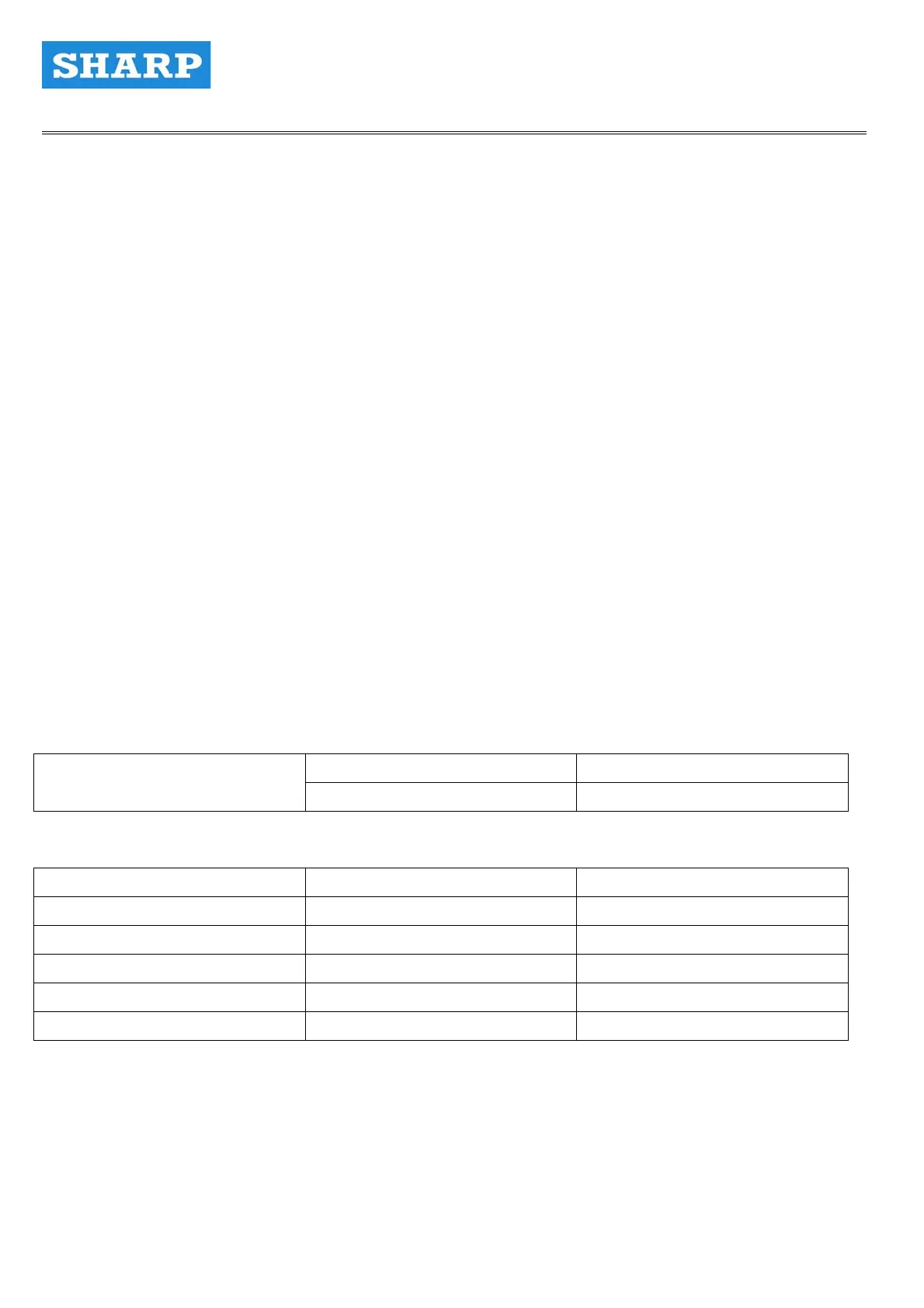

Spindle Rotation Speed (rpm) Cutter Diameter (mm) Cutter Length (mm)

6000 – 8000 125 250

8000 – 10000 100 250

10000 – 12000 80 250

12000 – 15000 65 200

15000 – 18000 50 200

Loading...

Loading...