555970 MARK V – MOUNTED OVERARM PIN ROUTER

26

Screw-down fixtures are the easiest type of

fixture to use and generally take less time to

make than clamp-in fixtures. As shown in

our example, they can be used to duplicate

such things as award or tole painting

plaques, round or oval picture frames and

similar items.

If you’re making a large quantity of dupli-

cate products, assembly and disassembly

time can be reduced by using needlepoint

utility screws to eliminate starter holes, and

a power screwdriver or variable speed re-

versible hand drill with a screwdriver bit to

drive them into position.

This approach may not work and pilot holes

could be required if the screws are near the

edges of your workpieces. And remember. ..

making several identical fixtures also will

speed up large quantity production time.

NOTE

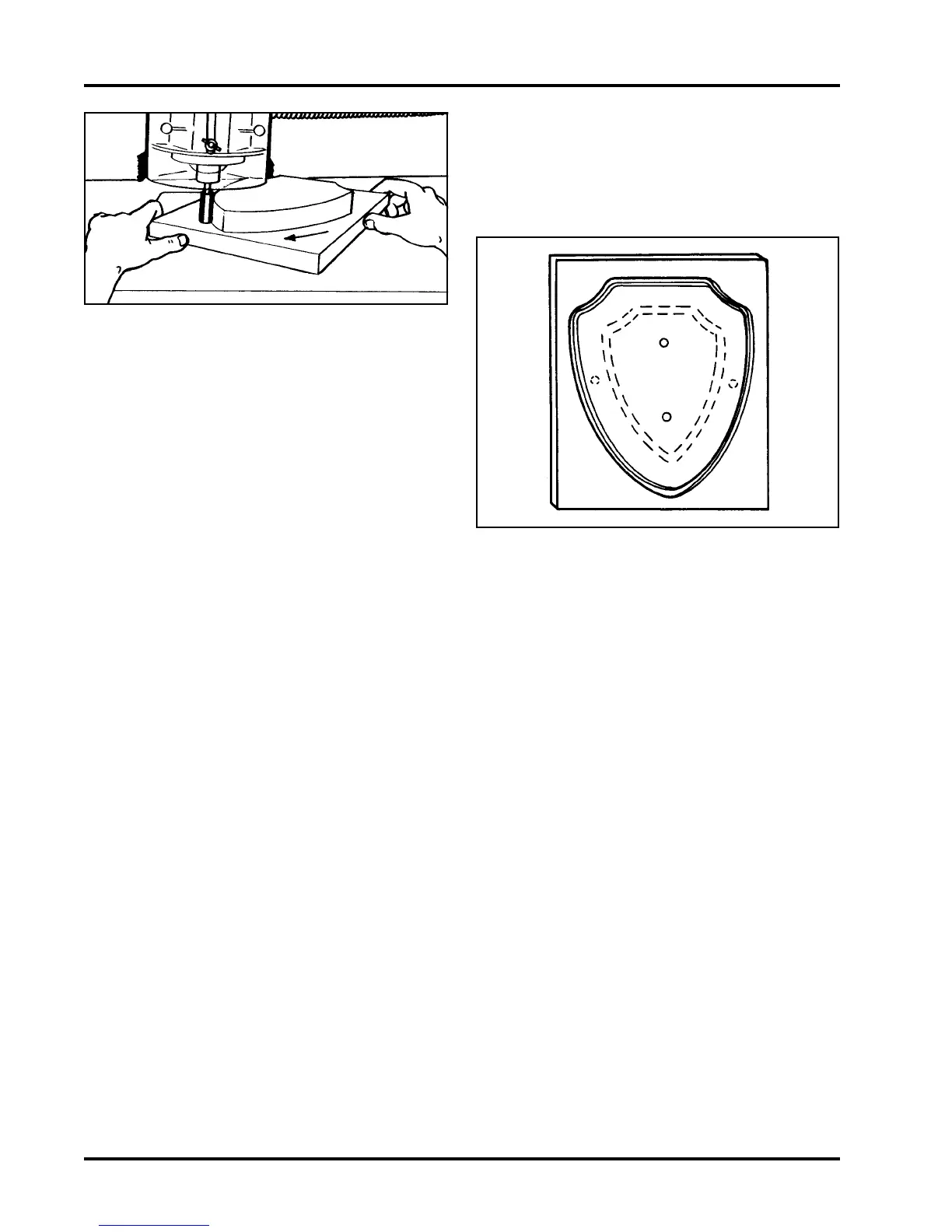

In our plaque example, by adding an addi-

tional groove to the fixture (see broken

lines in Figure 17) and making the overall

size of the fixture larger, you can actually

form three projects from a single piece of

stock .

(1) A square picture frame with a plaque-

shaped opening.

(2) A plaque-shaped picture frame with a

plaque-shaped opening.

(3) A smaller plaque for tole painting or

decoupage.

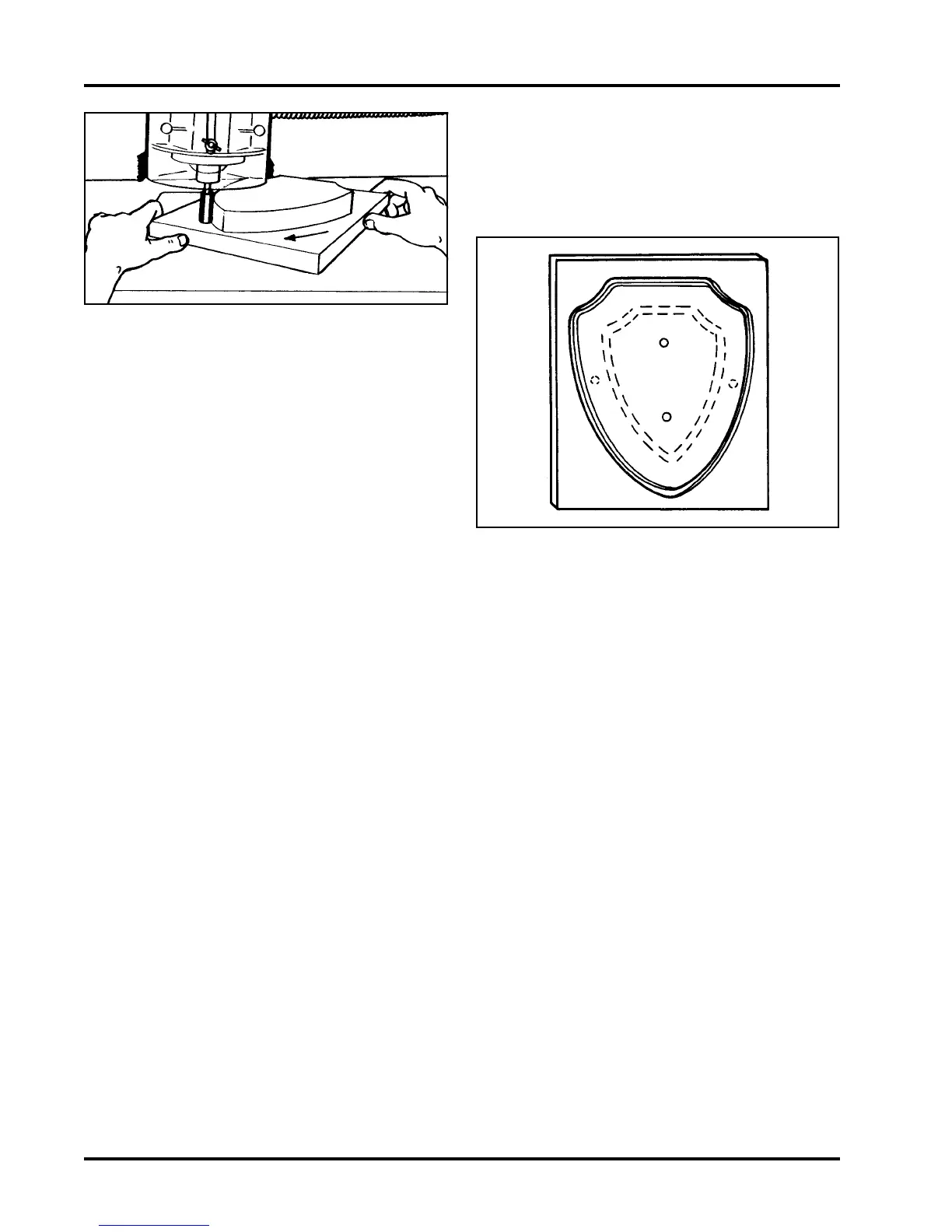

Step 1: Screw the appropriate sized guide

pin into the center hole of the Router Table

Insert and align it with the same sized router

bit, as explained previously.

Step 2: Drop the fixture groove over the

Table Pin, turn on your router motor, and

set your final depth-of-cut so the bit just

barely breaks through the surface of the par-

ticleboard side of your fixture. Turn off your

router motor.

Step 3: Attach your workpiece to the fixture

Step 4: Drop the fixture groove over the

Table Pin, turn on your router motor, plunge

your rotating bit into the workpiece about

1/4" and start moving your fixture (with

workpiece attached) in a counter-clockwise

motion until you’ve completed your initial

cut in the first groove.

Step 5: Repeat the process for each groove

in your fixture.

Figure 16. Routing with a screw-down

fixture.

Figure 17. Getting multiple projects from

a single workpiece.

Loading...

Loading...