Mark V Model 520 Alignment

Page 2

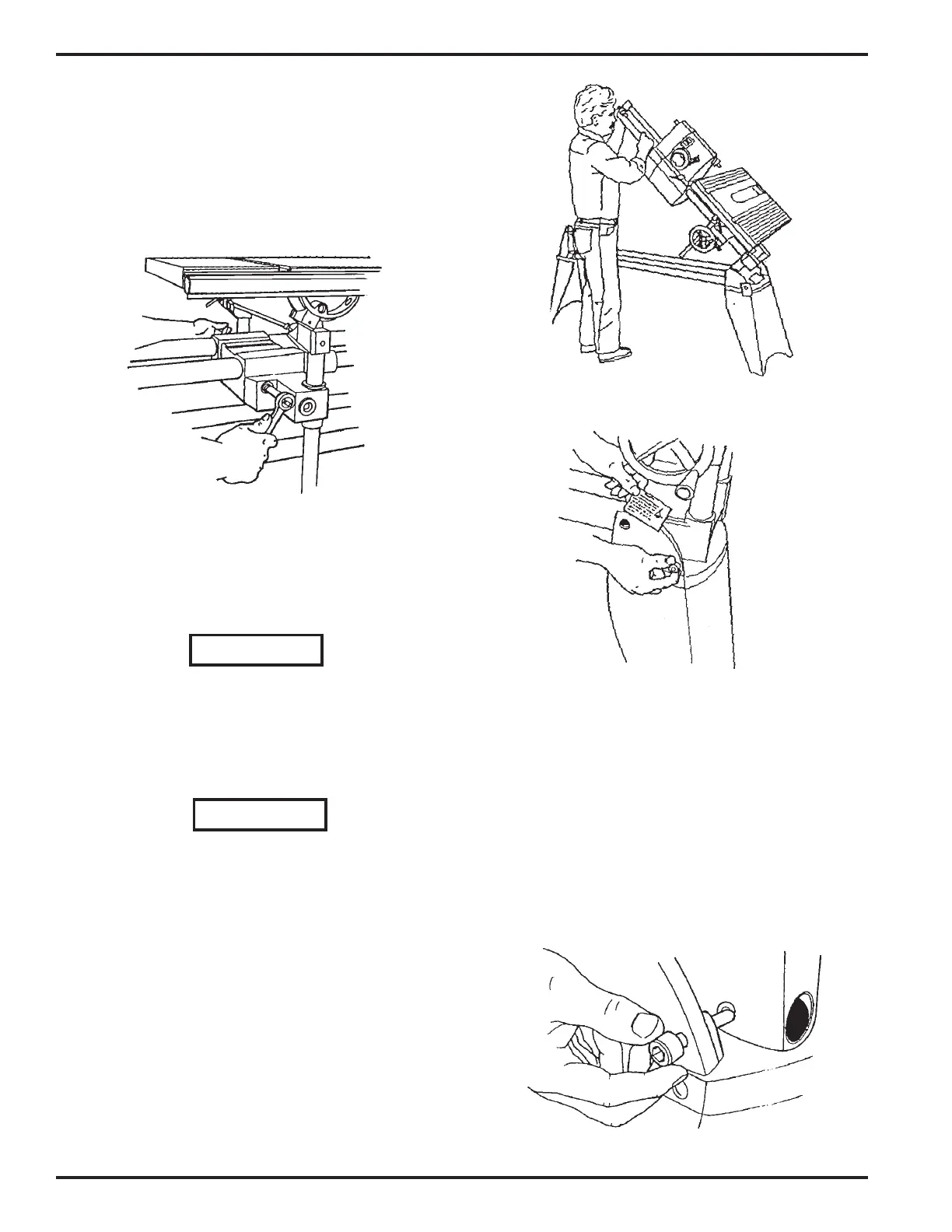

ADJUST THE CARRIAGE LOCK

3. If the carriage lock handle (187) does not lock

into the horizontal position or the carriage

moves out of position, the lock needs adjust-

ing. To adjust the lock, use a 1/2" socket with

an extension and ratchet handle to tighten or

loosen the nut located at the back of the

carriage assembly, as shown in Figure B-45.

Figure B-45

4. When the carriage lock handle locks into the

horizontal position and the carriage no longer

moves when the handle is in the horizontal

position, tighten the nut a final 1/4 turn.

WARNING

The carriage lock handle MUST lock into the

horizontal position, otherwise the carriage lock

may vibrate loose.

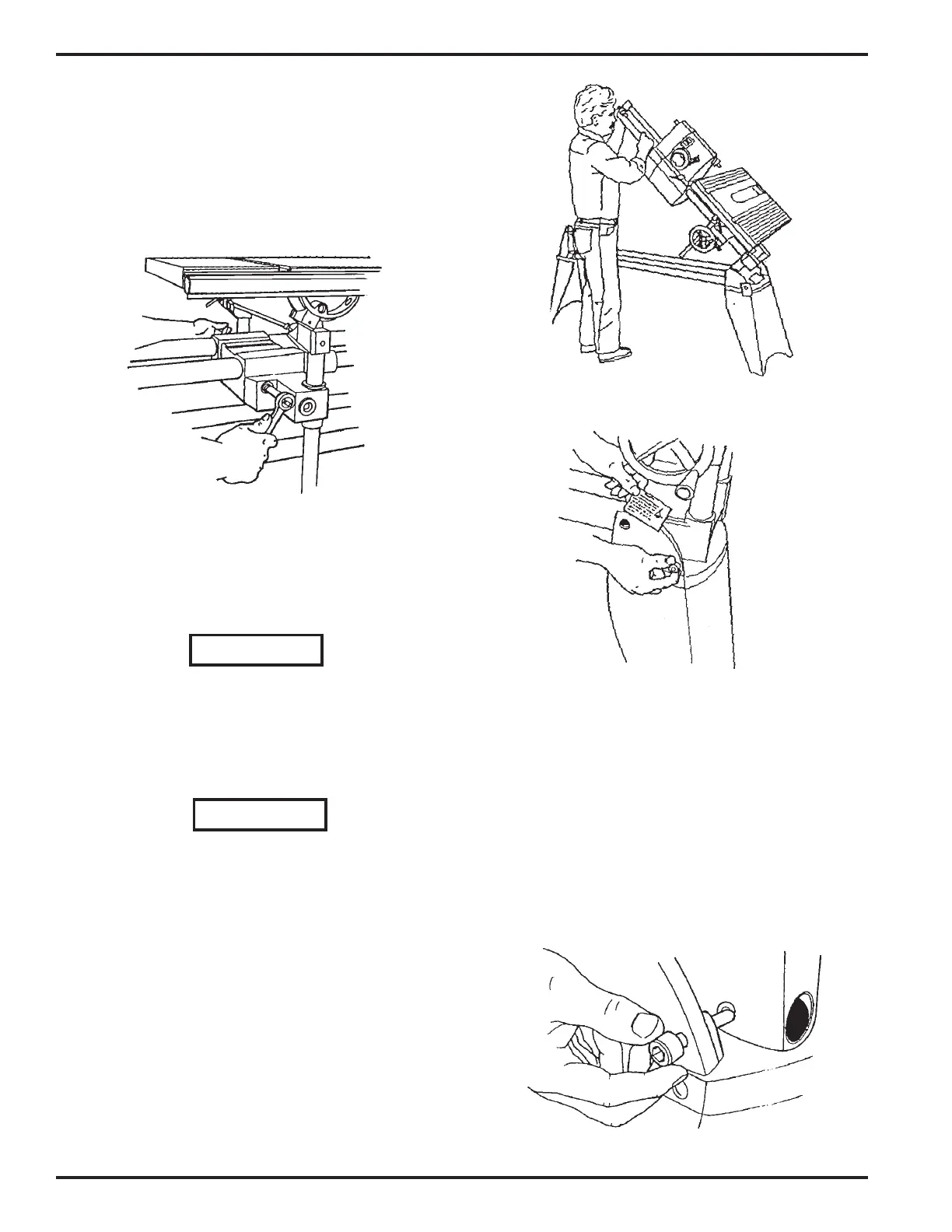

SET THE WORKTABLE'S 90° LEFT STOP

WARNING

Always make sure the Mark V headstock and

carriage are locked and all casters are raised off

the floor before lifting the Mark V into the vertical

drill press position.

5. Unlock the carriage and headstock. Move the

headstock to the middle of the way tubes.

Then move the carriage between the head-

stock and base mount (right side).

6. Tighten the headstock and carriage locks. Place

the Mark V in the vertical position by loosen-

ing the headrest handle (15), firmly grasping

the way tubes (20) near the headrest end, and

lifting the tubes into the 90° position, as dem-

onstrated in Figure B-46.

Figure B-46

Figure B-47

Figure B-48

7. See Figure B-47. Use your fingers to screw in

the base lock (2). Note the base lock is slightly

off center to the countersink found in the

bench base, as shown in Figure B-48. This

offset allows the base lock to more firmly hold

the base in place.

Loading...

Loading...