12-OPERATION 12-USO DELLA MACCHINA

A0398 69 F144/4-SX

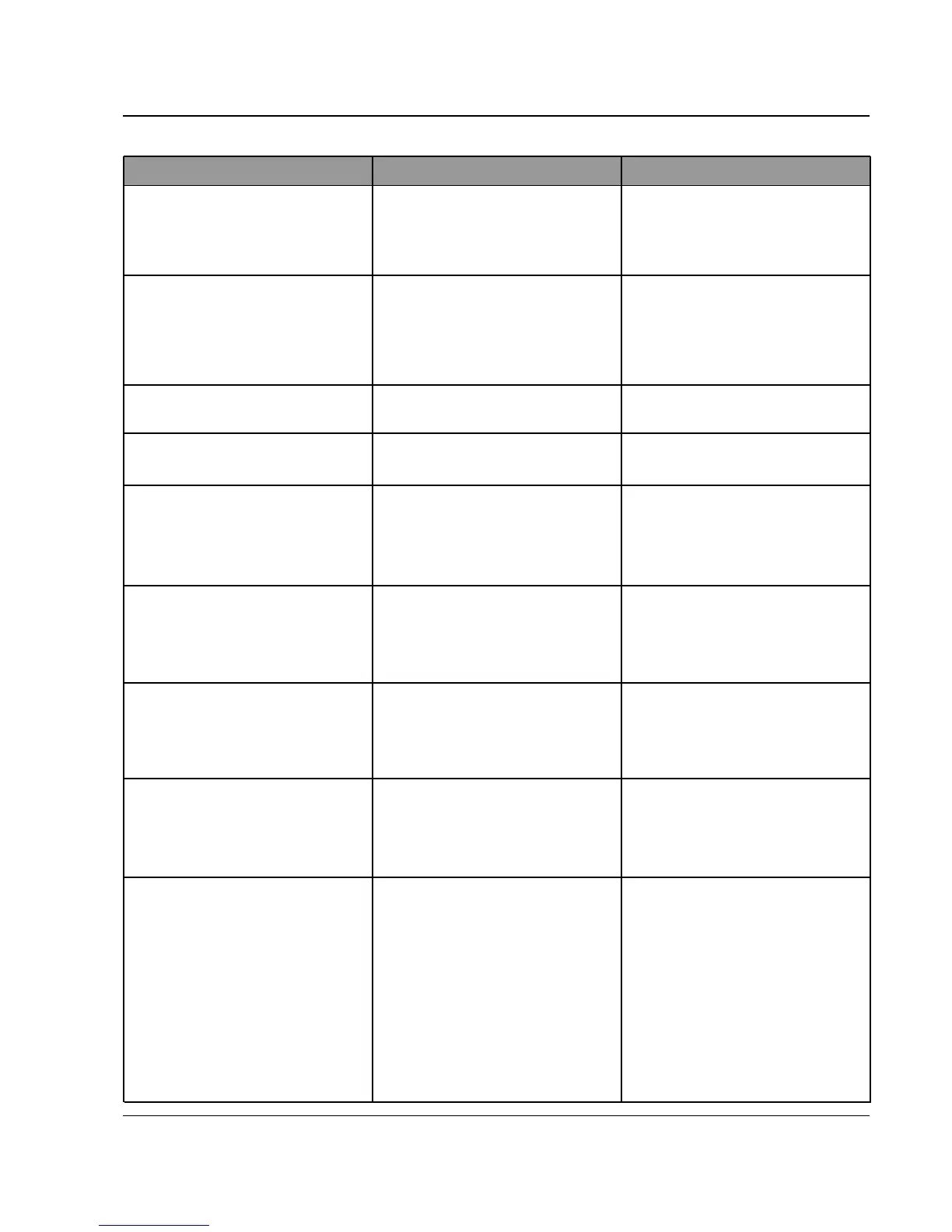

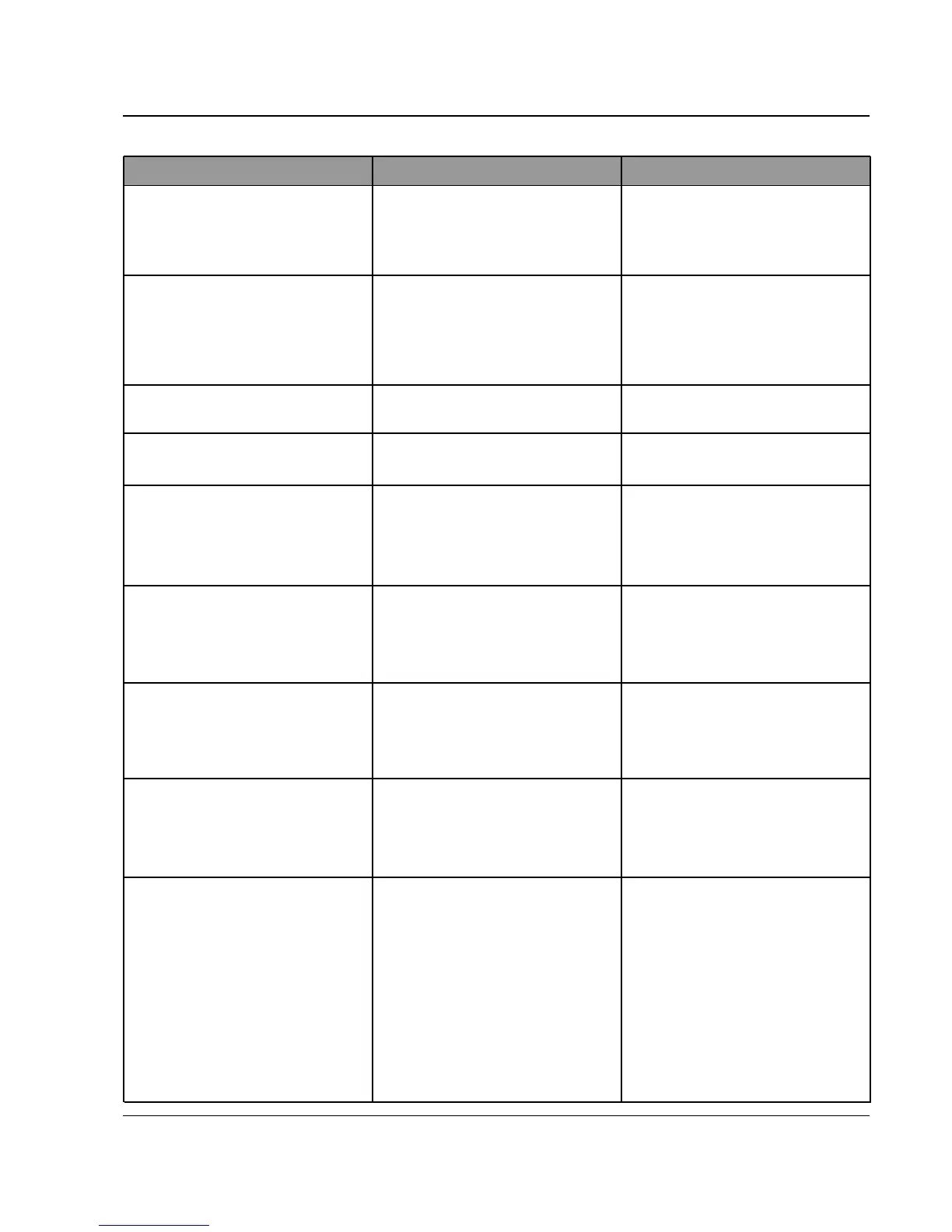

12.8 TROUBLE SHOOTING

SITUATION

Turning the mainswitch on ON, the

voltage lamp does not light up.

Pressing the START button, pressure the

suckers-holder carriage does not move.

The vacuum pump does not work.

Pressing the VACUUM PUMP button, the

motor devices do not turn.

The suckers do not take the cardboard.

The suckers-holder carriage goes

against the box storage.

The box is not opened by the suckers-

holder carriage.

During the back trip, the suckers-holder

carriage not stop in line with the driving

belts.

The machine stops without pushing the

box in the driving belts and the box falls

down.

CAUSE

EMERGENCY STOP button pressed.

Anti-accident guard open.

Magnetothermal.

Unsufficient air pressure.

The suckers-holder carriage is not in

position.

Solenoid valve N. 3.

Thermal switch N.12

Thermal switch

N. 11

Adjustment of height of box storage.

Speed of suckers-holder carriage;

Vacuum pump.

Sensor N. 2

Excessive distance between the sensor

and the suckers-holder carriage.

Box opener cylinder in a wrong position.

The back trip speed of the box opener is

too low.

Too high speed of the carriage.

Sensor N. 1

Wrong position of the sensor which

regulates the position of the

pushing carriage.

Uncorrect calibration of the sensor of

the vacuum pump.

SOLUTION

Check.

Check.

Check.

Adjust work to 6÷7 BAR

Press RESET

Check

Repair

Repair

Adjust

Adjust

Check

Check

Decrease the distance between them.

Adjust the position of the boxes in the

storage.

Slightly increase the back trip speed of the

suckers-holder carriage.

Decrease the speed acting on the does

regulator.

Adjust the distance between the sensor and

the suckers-holder carriage.

Adjust the position of the pushing

carriage (the best distance between

the slide and thepushing carriage

must be about 5mm higher than the

lenght of the box to be formed).

Adjust the sensitivity of the sensor.

Loading...

Loading...