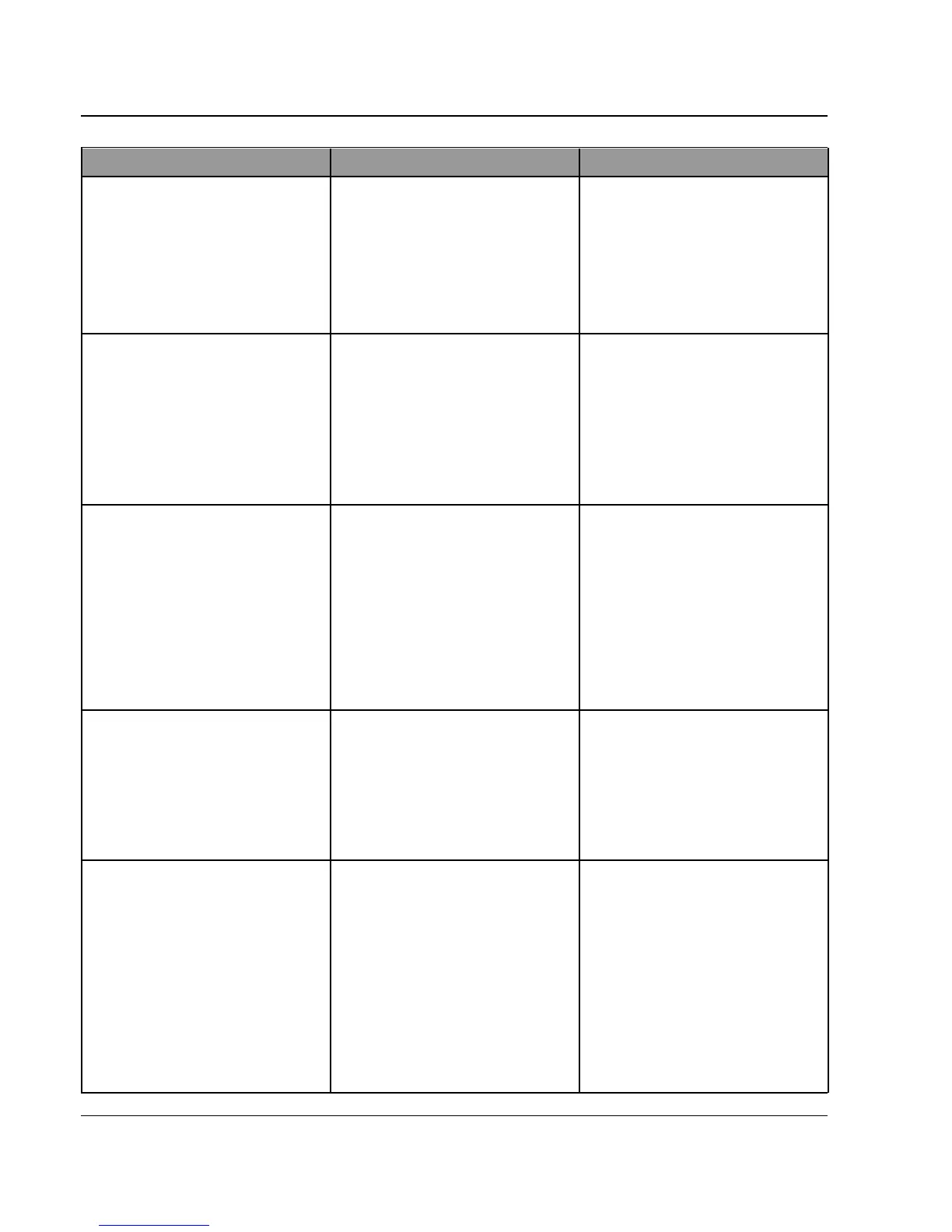

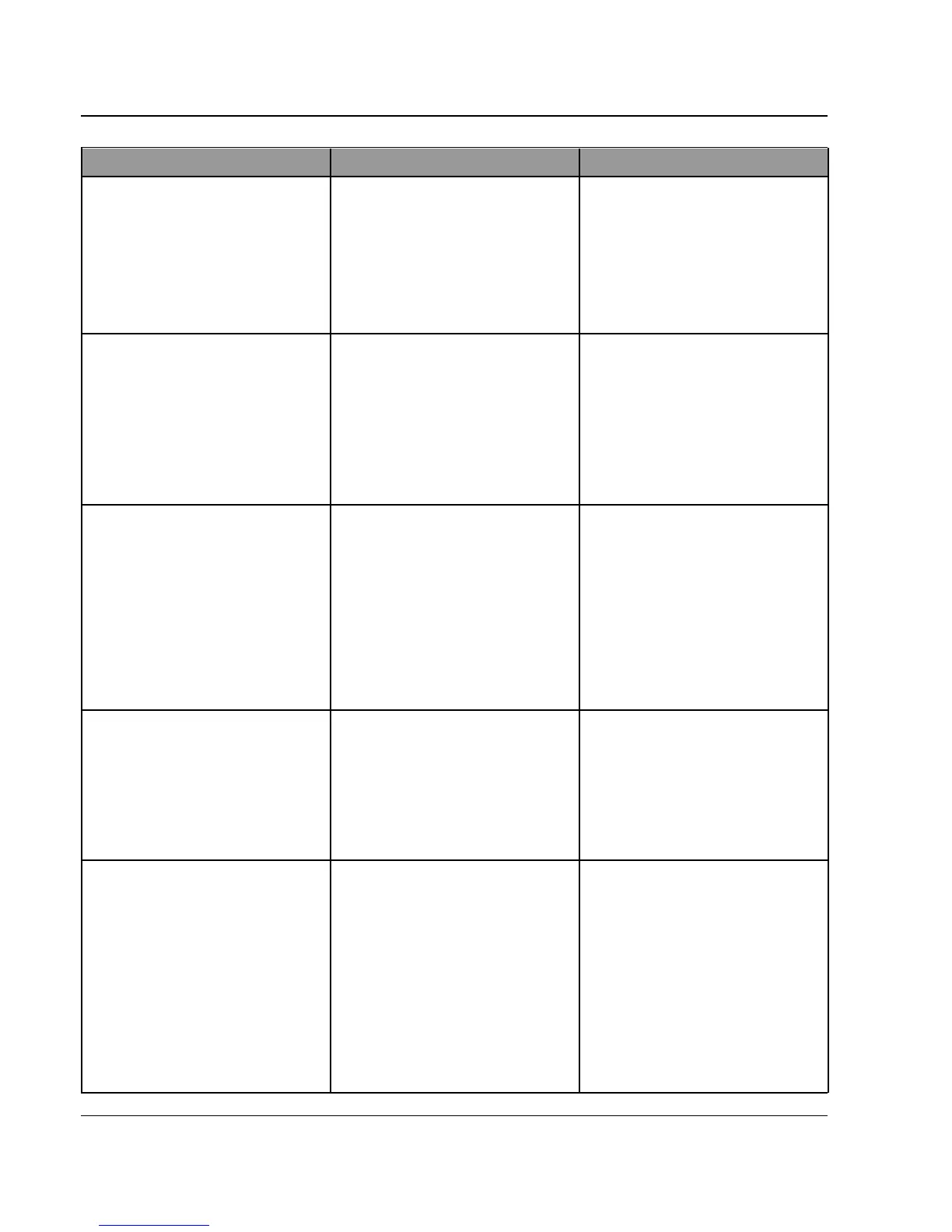

12-OPERATION 12-USO DELLA MACCHINA

F144/4-SX 70 A0398

SITUATION

The blade does not cut or grays the

tape.

The tape is not properly put on the back

part of the box.

The belts do not drive the box.

The tape is not centered on the box.

The box, although not open at the

driving belts, is pushed by the pushing

carriage.

CAUSE

Blade dirty of adhesive tape;

Unsufficient tape tensioning.

Cut levers springs not strong enough.

Damaged blade (Broken teeth)

The blade does not cut the tape

properly.

The tensioning of the main spring of the

taping unit is insufficient.

Adhesive clotting on the tape refeeding

rollers of the taping unit.

Rubber-coated roller at the exit.

Too low pressure.

Smooth ring on the pulley.

Excessive unrolling tensioning of the

tape.

Excessive tensioning of the spring of the

taping unit.

Excessive pressure of the head on the

box.

The driving guides are not correctly

positioned.

The laps is not positioned at the centre

of the taping unit.

The tape si not positioned at the centre

of the taping unit.

Uncorrect calibration of the sensor of

the vacuum pump.

SOLUTION

Clean

Increase the friction brake of the

tape drum.

Replace

Replace the blade

Replace/clean

Adjust the tensioning of the spring.

Clean and lubricate the refeeding

rollers.

Replace.

Adjust.

Replace.

Decrease friction on the drum.

Replace.

Adjust the position of the boxes'height

detector.

Check the position of the drive belts.

Make sure that the laps are centered.

Adjust the position of the tape.

Adjust the sensitivity of the sensor.

Loading...

Loading...